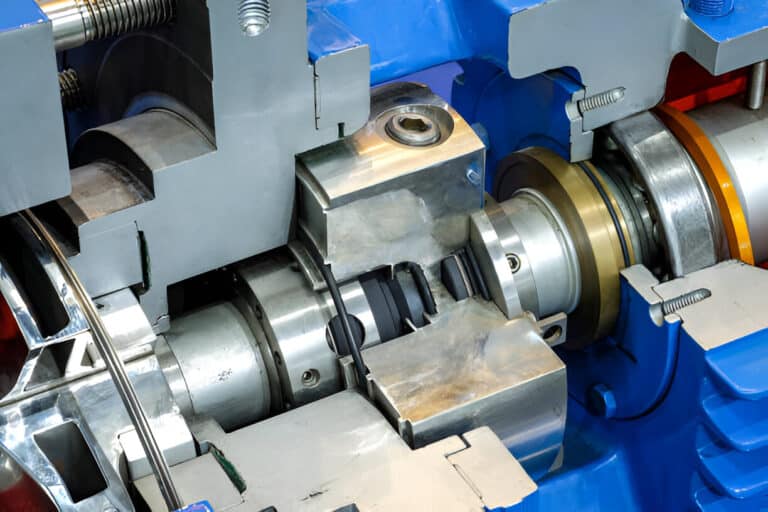

No, you should never run standard mechanical seals dry. Running a mechanical seal without proper lubrication will destroy it within minutes, causing expensive equipment damage and potential safety hazards.

Why Running Dry Destroys Mechanical Seals

Running a mechanical seal dry is like driving your car without oil – friction quickly generates extreme heat that destroys the components. The two seal faces need constant lubrication to function properly.

When liquid flows between the seal faces, it does three critical jobs. First, it reduces friction between the moving parts. Second, it carries away heat generated by the rotation. Third, it maintains the microscopic gap that allows the seal to work without wearing out.

Without this liquid film, the seal faces grind directly against each other. This metal-on-metal contact creates temperatures exceeding 1,000°F within seconds.

What Happens When You Run a Seal Dry

The destruction happens fast – usually within 30 seconds to 5 minutes. Here’s the typical sequence of failure:

First, the seal faces start generating extreme heat from friction. You might hear a high-pitched squeal or grinding noise as the surfaces scrape against each other.

Next, the heat causes the seal faces to crack, warp, or shatter. Carbon faces often turn to dust, while harder materials like silicon carbide can explode from thermal shock.

Finally, the damaged seal completely fails. This leads to massive leakage, potential pump damage, and possible safety hazards if handling dangerous chemicals.

The damage extends beyond just the seal. The excessive heat can damage the pump shaft, bearings, and housing, turning a $200 seal replacement into a $5,000 pump rebuild.

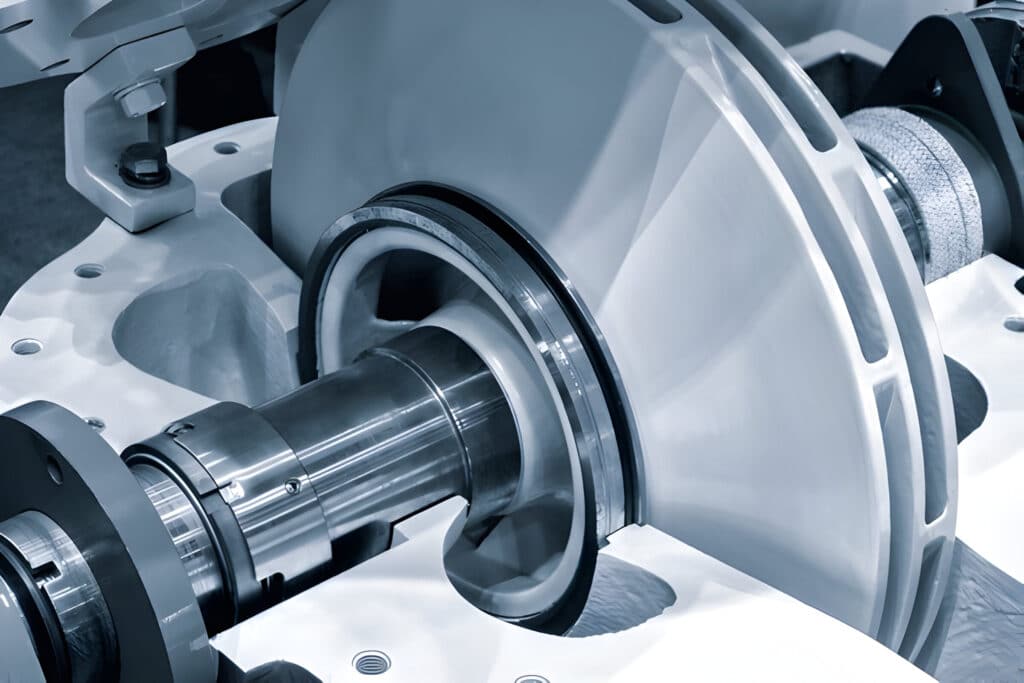

Special Seals Designed for Dry Running

Some specialized mechanical seals can handle limited dry running, though they’re the exception, not the rule. These cost significantly more than standard seals.

Gas seals use special face designs and materials that can operate with minimal lubrication. They’re commonly used in compressors handling gases instead of liquids.

Dry-running seals incorporate features like specialized coatings or self-lubricating materials. They might survive brief periods without liquid but still can’t run completely dry indefinitely.

Even these special seals have strict limitations. Most can only handle dry running for a few minutes during startup or shutdown, not continuous operation.

FAQs

How long can a mechanical seal run dry before failing?

Standard mechanical seals fail within 30 seconds to 5 minutes of dry running. The exact time depends on rotation speed, seal materials, and size, but damage starts immediately.

Can you repair a mechanical seal that ran dry?

No, you cannot repair a seal damaged by dry running. The seal faces experience permanent damage like cracking, warping, or material transfer that makes them unusable.

What materials handle dry running best?

Silicon carbide against carbon graphite tolerates brief dry running better than other combinations. However, even these materials fail quickly without proper lubrication, typically lasting only minutes longer than standard materials.