Never touch a mechanical seal while equipment is running—it could seriously injure you or damage expensive equipment. These precision devices seal rotating shafts in pumps and compressors, operating under extreme pressure, temperature, and speed.

You can only safely handle a mechanical seal after completely shutting down the machine, locking it out, and relieving all pressure. Even then, you need proper training, clean gloves, and careful handling to avoid contaminating the ultra-smooth sealing surfaces that prevent leaks.

Touching a Mechanical Seal: Operation Vs. Shutdown

Running equipment means hands off—period. A mechanical seal sits where a spinning shaft meets the pump housing, surrounded by moving parts that can grab fingers or clothing in an instant.

During operation, seals can reach temperatures over 280°F and contain fluids under hundreds of pounds of pressure. Safety guards cover these areas for good reason. Removing them to touch a seal violates basic safety rules and could cost you fingers—or worse.

Only touch a seal when the equipment is completely dead. This means following lockout/tagout procedures: disconnect power, lock the switch, drain pressure, and wait for everything to cool down.

Even experienced mechanics verify the shaft won’t turn before starting work. One test? Try to start the equipment after locking it out. If nothing happens, you’re safe to proceed.

Safety Risks of Physical Contact with Seals

High Temperature Burns

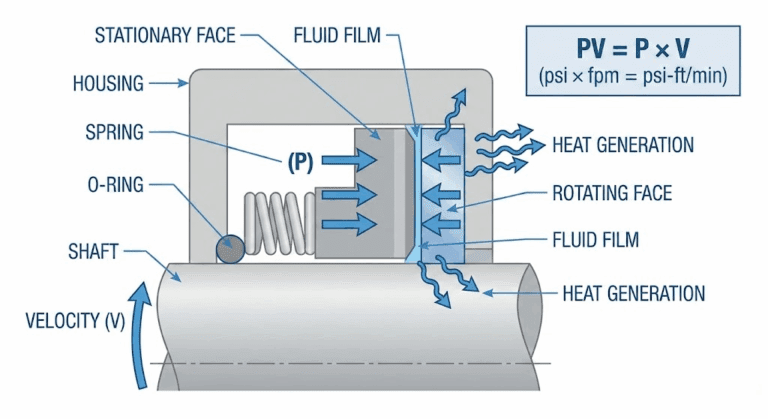

Mechanical seals get hot—really hot. Friction between the rotating faces generates heat, and process fluids can be scalding.

Even seals handling room-temperature water heat up from friction. Touch one right after shutdown and you’ll get burned. Always let equipment cool completely before maintenance.

Pressure Release and Fluid Injection

Seals contain fluids under serious pressure—often 150+ PSI. Disturb a seal that’s still pressurized and you risk a high-pressure spray.

These jets can inject fluid under your skin or spray dangerous chemicals everywhere. Never assume a seal area is depressurized. Always verify with gauges and drain valves first.

Chemical Exposure

Industrial pumps move all kinds of nasty stuff—acids, caustics, solvents. The seal area often has invisible residue from these chemicals.

Touch without protection and you might get chemical burns. Some fluids release toxic vapors when disturbed. Always know what fluid you’re dealing with and wear appropriate gloves.

Moving Parts and Entanglement

The shaft near a seal spins fast—sometimes thousands of RPM. Loose clothing, long hair, or fingers can get caught instantly.

Large pumps keep spinning even after power cuts off. Never trust your eyes alone. Physically verify the shaft is locked before approaching.

Lapped Faces Damage

Seal faces are polished smoother than glass—we’re talking millionths of an inch. One fingerprint ruins this finish.

Oil from your skin creates leak paths. Even tiny fibers from paper towels can cause failure. This is why pros never touch seal faces directly, even with clean hands.

Best Practices for Mechanical Seal Touching

1. Shut Down and Isolate First

Stop the machine completely using proper lockout/tagout procedures. This isn’t optional—it’s the law in most places.

Lock out all energy sources. Tag them with your name. Test the start button to confirm it’s dead.

Then relieve system pressure through drain valves. Let hot equipment cool for at least 30 minutes. Some large pumps need hours to cool safely.

2. Maintain Cleanliness and Avoid Direct Contact

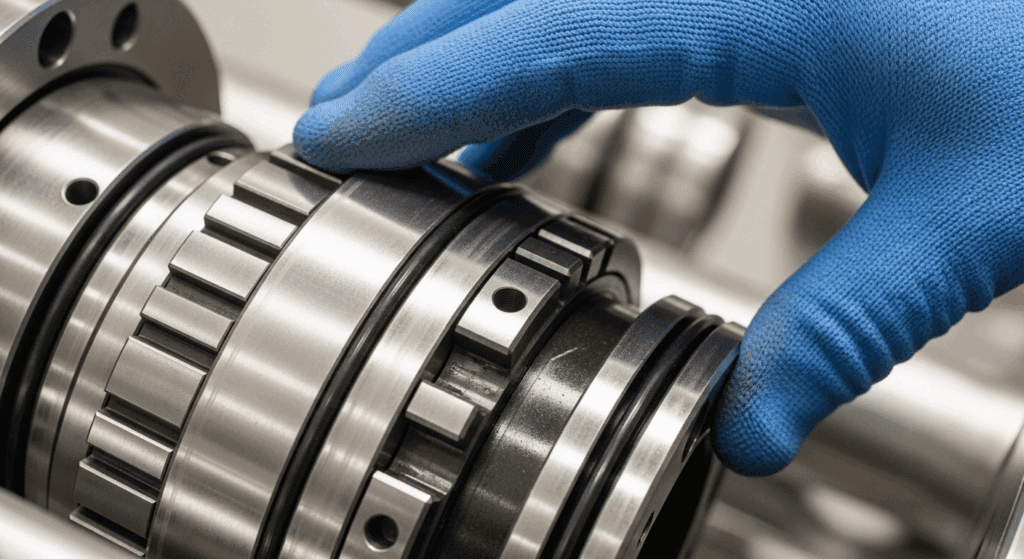

Wear clean, lint-free gloves—always. Nitrile or latex gloves keep oils off seal faces while protecting your hands.

Never touch the polished seal faces, even with gloves. If you accidentally touch them, clean immediately with isopropyl alcohol and lint-free wipes.

Set seal parts on clean cloth or paper, never directly on workbenches. Treat these components like surgical instruments—because that’s basically what they are.

3. Handle Components Gently and Inspect Them

Seal faces are often ceramic or carbide—hard but brittle. Drop one and it shatters like glass.

Inspect every component before installation. Look for chips, scratches, or dirt. Even a hair across the seal face causes leaks.

Check O-rings for cuts or nicks. Roll them between your fingers to feel for damage you can’t see. Replace anything questionable—it’s cheaper than a comeback.

4. Follow Manufacturer Instructions

Every seal comes with specific installation instructions. Read them. Follow them. No exceptions.

Manufacturers specify exact torque values, alignment tolerances, and assembly sequences. Skipping steps or improvising causes most seal failures.

Keep instruction sheets handy during installation. Even experienced mechanics reference them—there are too many seal types to memorize everything.

Use the recommended tools, not whatever’s handy. Special sleeves protect seals during installation. Setting clips ensure proper spacing. These tools exist for good reasons.