I’ve spent years troubleshooting pump failures, and the question that keeps coming up is whether mechanical seals can run without seal water. The short answer? Yes, they absolutely can.

Mechanical seals work without seal water through four main methods: dry gas seals that use pressurized nitrogen to create a non-contacting gas film, self-lubricating face materials like carbon graphite, process fluid lubrication where the pumped liquid itself lubricates the seal faces, and internal circulation designs that eliminate external flush piping.

What Methods Allow Mechanical Seals to Operate Without Seal Water?

How Do Dry Gas Seals Create a Non-Contacting Seal?

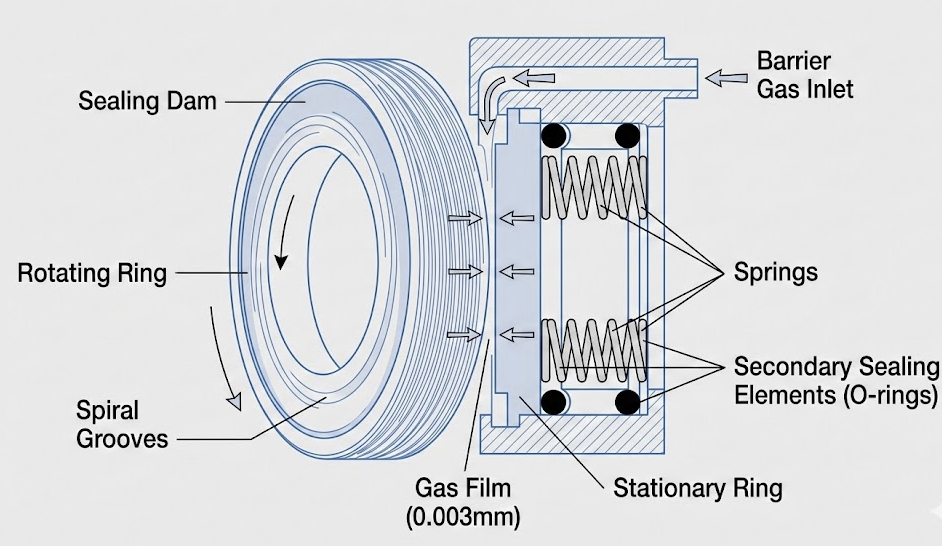

Dry gas seals use a thin film of pressurized gas—usually nitrogen—to keep the rotating and stationary seal faces completely separated. No liquid, no contact, no wear.

The secret is in the spiral grooves etched into the rotating face. When the shaft spins, these grooves act like tiny pumps, drawing gas inward and compressing it against a sealing dam. This creates enough pressure to lift the stationary face away from the rotating one.

The gap between the faces is incredibly small—about 0.003mm, roughly 1/10th the thickness of a human hair. But that tiny gap is enough to prevent contact while keeping leakage to near-zero levels.

How Does Process Fluid Lubrication Work?

Process fluid lubrication uses the liquid you’re pumping to lubricate the seal faces. No external water supply needed.

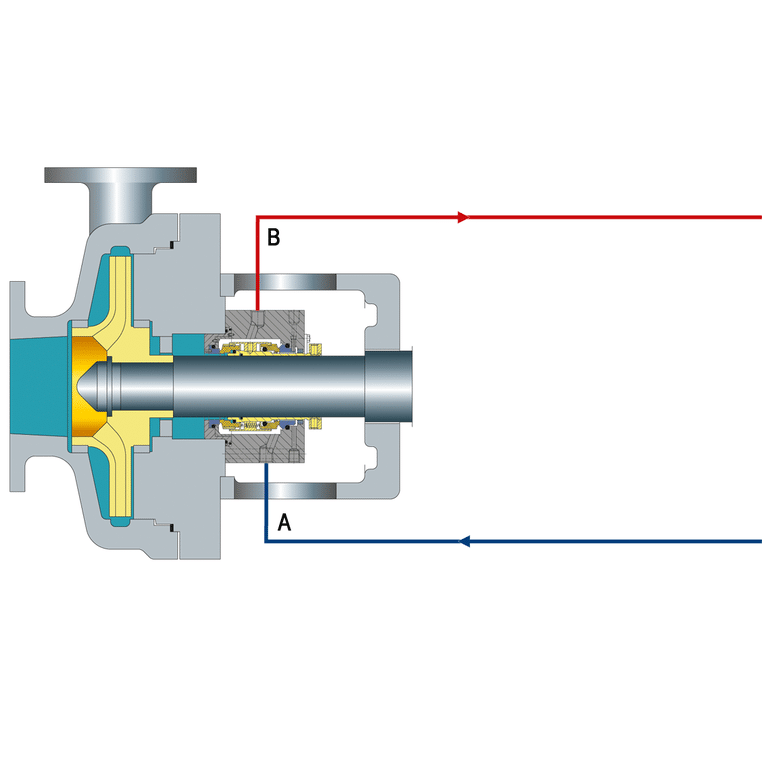

In the simplest setup—API Plan 01—the pump’s own internal passages circulate fluid from the discharge side to the seal chamber. The pressure difference drives flow without any external piping.

This approach works well when you’re pumping clean fluids at moderate temperatures. The process fluid creates a hydrodynamic film between the seal faces, providing both cooling and lubrication.

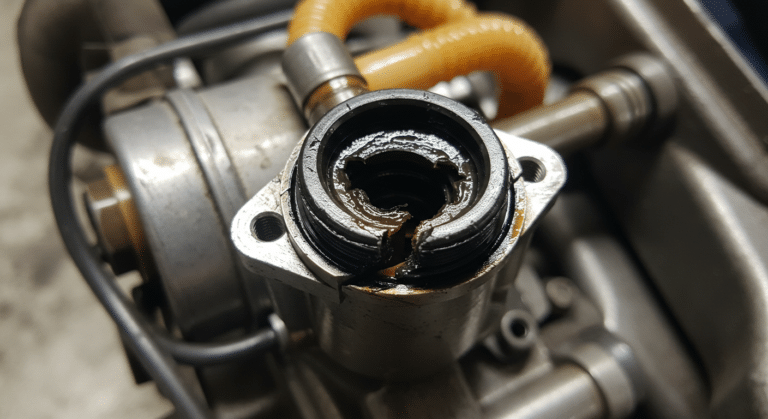

But there’s a catch. If your pumpage contains abrasives, runs too hot, or doesn’t lubricate well, you’ll wear out the seal faces fast.

What Self-Lubricating Materials Enable Dry Running?

The right face material can handle brief dry running without external lubrication. Here’s how the main options compare:

| Material | Self-Lubrication | Max Temperature | Best For |

|---|---|---|---|

| Carbon Graphite | Excellent | 350°C (662°F) | General dry running, gas seals |

| Silicon Carbide | Good | 500°C+ (932°F+) | High wear, abrasive conditions |

| Graphite-Loaded SiC | Very Good | 450°C (842°F) | Harsh conditions with limited lubrication |

Carbon graphite is my go-to for most dry running applications. The graphite particles act like millions of tiny lubricant reservoirs, depositing a protective film on the mating face as the seal operates.

Silicon carbide handles abuse better—it’s nearly as hard as diamond with a Mohs hardness of 9-9.5. But it doesn’t self-lubricate as well as carbon.

The best of both worlds? Graphite-loaded silicon carbide. It combines SiC’s toughness with graphite’s lubricity. I recommend it for applications where you need wear resistance but can’t guarantee constant lubrication.

What Are the API Piping Plans for Gas-Lubricated Seals?

How Does API Plan 72 (Buffer Gas) Work?

API Plan 72 supplies a buffer gas—typically nitrogen—to sweep away any leakage from the inner seal. It’s like having a constant, gentle breeze pushing vapors toward a collection system.

The key detail: buffer gas pressure stays BELOW the seal chamber pressure. The gas doesn’t prevent the process fluid from reaching the inner seal. It just dilutes and carries away whatever leaks past.

Here’s how it flows:

- Nitrogen enters the space between the inner and outer seals

- The gas mixes with any process fluid vapor

- The mixture vents to a collection system or flare

I recommend Plan 72 when you need to handle small amounts of leakage without letting it escape to atmosphere. It works well with volatile hydrocarbons where you want to reduce the explosion hazard around the seal.

How Does API Plan 74 (Barrier Gas) Differ?

API Plan 74 takes a more aggressive approach. It pressurizes the barrier gas to at least 25 PSI (1.7 bar) ABOVE the seal chamber pressure. This prevents any process fluid from reaching the outer seal.

With Plan 74, you’re creating an absolute barrier. Nothing gets past the inner seal because the pressure gradient pushes everything back into the process.

This setup requires:

- A pressure-regulated gas supply system

- Continuous monitoring of barrier gas pressure

- A reliable nitrogen source (don’t rely on gas bottles)

Plan 74 is your choice when zero emissions matter—pharmaceutical applications, toxic chemicals, or anywhere you can’t tolerate any process leakage to atmosphere.

But watch out for one gotcha: the high-pressure nitrogen will leak INTO your process. If that contamination matters, you’ll need to account for it.

Conclusion

Mechanical seals can work without seal water through four proven methods: dry gas seals with spiral groove technology, self-lubricating face materials, process fluid lubrication, and internal circulation designs.

The right choice depends on your specific application. Dry gas seals deliver the best performance for compressors and gas-handling equipment. Process fluid lubrication works well for clean liquids at moderate conditions. Self-lubricating materials handle intermittent dry running when liquid lubrication isn’t guaranteed.