Mechanical seals eat up 70% of your pump maintenance budget. That’s not a typo.

I’ve watched procurement teams spend weeks negotiating pump prices, only to see those savings vanish when seals fail every few months. The culprit? Wrong flush plan selection.

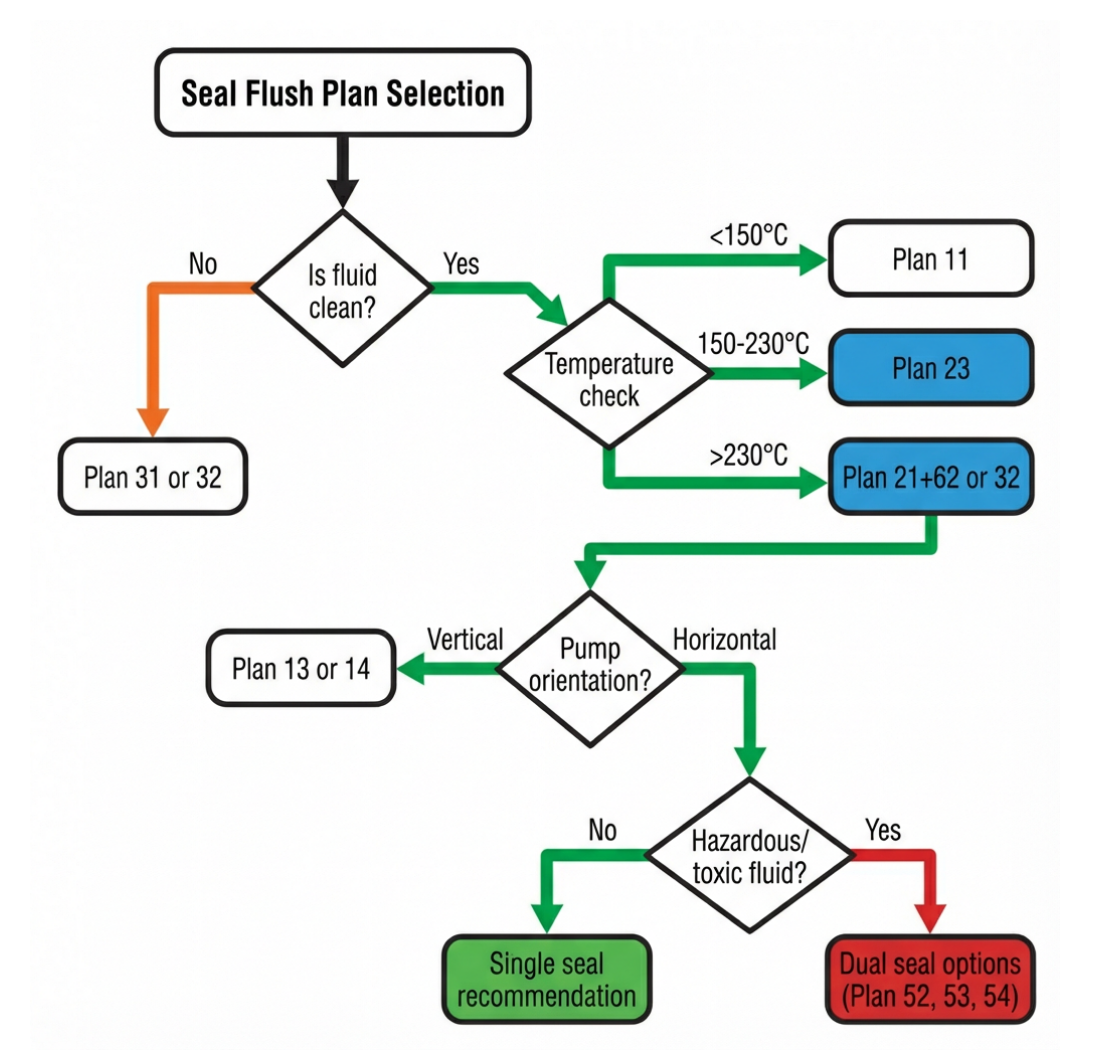

Match your flush plan to your fluid and conditions. Use Plan 11 for clean, cool fluids below 150°C. Switch to Plan 23 for hot water and hydrocarbons between 150-230°C. Go with Plan 32 when you’re dealing with dirty, abrasive, or corrosive fluids. And if you’re handling toxic or hazardous materials, dual seal Plans 52, 53, or 54 are your only real options.

What Are the Key Factors That Determine Flush Plan Selection?

Three things drive your flush plan choice: what you’re pumping, how you’re pumping it, and what happens if it leaks.

What Process Fluid Characteristics Must You Evaluate?

Your fluid tells you almost everything you need to know.

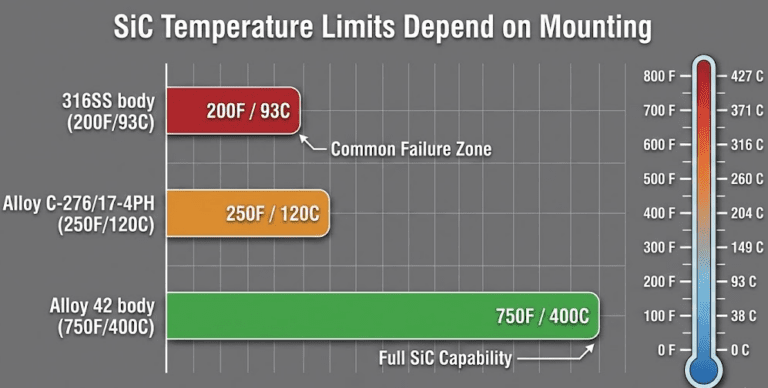

Temperature and vapor pressure come first. A flush plan must keep your seal faces at least 50 psi above the fluid’s vapor pressure. Drop below that, and the fluid flashes to vapor between the seal faces. No lubrication. Rapid failure.

Cleanliness matters more than you’d think. Solid particles act like sandpaper on seal faces. If your fluid carries suspended solids, you need a plan that either removes them (Plan 31’s cyclone separator) or bypasses them entirely with external clean flush (Plan 32).

Lubricity and compatibility affect seal face life directly. Water has terrible lubricity compared to hydrocarbons. That’s why boiler feed water applications almost always need Plan 23’s cooled circulation – it maximizes the lubricating film between faces.

Flashing and solidification tendencies create special challenges. Fluids that polymerize, coke, or crystallize when they contact atmosphere need quench plans (like Plan 62) to prevent buildup on the atmospheric side of the seal.

What Operating Conditions Affect Your Choice?

Pump orientation changes everything. Horizontal pumps work fine with Plan 11. Vertical pumps trap air at the seal faces – a death sentence for dry-running seals. You’ll need Plan 13 or 14 to vent that air automatically.

Seal chamber pressure determines whether process fluid flows into or out of the seal chamber. Higher discharge pressure relative to suction creates the circulation that makes Plan 11 work.

Cooling water availability limits your options. Plans 21, 23, and many dual seal systems need cooling water. If your plant doesn’t have reliable cooling water at the pump location, you’ll need to work around that constraint.

What Safety and Environmental Requirements Apply?

Hazardous fluids demand dual seals. There’s no way around this. If a primary seal failure could expose workers to toxic materials or create environmental violations, you need a backup seal with barrier fluid between the process and atmosphere.

Emission regulations are tightening. Even “safe” fluids face VOC restrictions. Plan 52’s unpressurized buffer system catches leakage past the primary seal. But remember – that reservoir must vent to a flare or vapor collection system, not atmosphere.

Zero-leakage requirements push you toward pressurized barrier plans (53A, 53B, 53C, or 54). The barrier fluid pressure exceeds seal chamber pressure, so any leakage goes into the process – not out to atmosphere.

How Do You Select a Flush Plan for Single Seal Applications?

Single seals handle 80% of pump applications. Here’s how to pick the right flush plan for yours.

Step 1: Start With the Default – Plan 11

Plan 11 works for 50-75% of all seal installations. It’s simple, cheap, and effective.

How it works: A small line taps off the pump discharge and routes fluid through a flow control orifice into the seal chamber. The higher discharge pressure pushes fluid across the seal faces, providing lubrication and carrying away heat.

Use Plan 11 when:

- Your fluid is clean (no suspended solids)

- Temperature stays below 150°C (300°F)

- You have adequate vapor margin (50 psi above vapor pressure in the seal chamber)

- The fluid provides good lubrication

Key specifications to remember:

- Minimum orifice bore: 3mm (1/8 inch)

- Tubing: 12mm minimum for shafts under 60mm

- Material: 300 series stainless steel

Watch for this failure mode: Clogged orifices kill more Plan 11 installations than anything else. Monitor the temperature differential across the orifice. If it drops more than 10%, the orifice is plugging. Clean it immediately or switch to a different plan.

Step 2: Add Cooling If Temperature Is High – Plan 21 or 23

When your process temperature exceeds 150°C, Plan 11’s simple circulation can’t keep seal faces cool enough. You need active cooling.

Plan 21 takes discharge fluid through a cooler before sending it to the seal chamber. It’s a single-pass system – fluid enters the seal chamber, mixes with process fluid, and leaves.

Plan 23 creates a closed loop. A pumping ring in the seal circulates fluid through a cooler and back to the seal chamber. The same fluid recirculates continuously.

| Feature | Plan 21 | Plan 23 |

|---|---|---|

| Cooling efficiency | Lower | Higher |

| Installation complexity | Simpler | Requires precise placement |

| Best temperature range | 150-200°C | 150-230°C |

| Fluid compatibility | Any pumpable fluid | Fluids that don’t foul coolers |

| Typical application | General hot service | Boiler feed water, hot hydrocarbons |

My recommendation: Plan 23 delivers better cooling, but it’s fussier to install. The cooler must sit within 3 meters of the seal and 18-24 inches above it. Get this wrong, and the pumping ring can’t overcome friction – you’ll get no circulation at all.

For most hot hydrocarbon services, Plan 21 is easier to make work reliably. Save Plan 23 for boiler feed water and other applications where you absolutely need that extra cooling efficiency.

Step 3: Use External Flush for Problem Fluids – Plan 32

Some fluids just can’t lubricate a seal properly. Slurries grind faces apart. Polymerizing fluids gum up the works. Acids attack seal components. When your process fluid is the problem, bring in clean fluid from outside.

Plan 32 injects clean fluid from an external source directly into the seal chamber. A close-clearance throat bushing keeps most of the external fluid in the seal chamber while allowing a small flow into the process.

Use Plan 32 when dealing with:

- Abrasive slurries and fluids with suspended solids

- Polymerizing or coking fluids

- Corrosive acids

- Fluids with poor lubricity

- High-temperature services where process fluid isn’t compatible with seal materials

Critical pressure requirement: Your external flush must run 10-15 psi above seal chamber pressure. Too low, and process fluid contaminates the seal chamber. Too high, and you crush the lubricating film between seal faces.

Flow rate rule of thumb: 1 gallon per minute for each inch of seal diameter at 3600 RPM. A 2-inch seal needs about 2 GPM of flush flow.

How Do You Select a Flush Plan for Vertical Pumps?

Vertical pumps need special attention. The physics work against you.

Why Is Venting Critical for Vertical Installations?

Picture a vertical pump. The seal chamber sits at the top of a closed cavity. Any air or vapor in the system rises and collects right at the seal faces.

That trapped air creates a dry-running condition. Without liquid between the faces, seal materials generate massive friction heat. They fail fast.

Plan 11 doesn’t solve this problem. Fluid enters the seal chamber, but there’s no path for trapped air to escape. Even if operators vent the chamber before startup, vapors can accumulate during operation.

Which Plans Work Best for Vertical Pumps?

Plan 13 routes fluid from the seal chamber back to pump suction through a flow control orifice. This creates continuous venting – air and vapors get swept back into the process stream instead of accumulating at seal faces.

Plan 14 combines discharge-to-seal with seal-to-suction flow. Fluid enters from discharge, passes through the seal chamber, and exits to suction. It’s self-venting and maintains good circulation.

| Feature | Plan 13 | Plan 14 |

|---|---|---|

| Flow direction | Seal chamber to suction | Discharge to seal to suction |

| Venting | Continuous | Continuous |

| Heat removal | Good | Better |

| Best for | Standard vertical pumps | Vertical pumps needing extra cooling |

My preference: Plan 14 handles most vertical pump applications well. It provides better heat removal than Plan 13 and vents continuously. Use it as your default for vertical installations.

How Do You Choose Between Dual Seal Flush Plans?

When single seals aren’t enough, dual seals provide backup protection. But which flush plan? That depends on whether you need buffer or barrier protection.

Step 1: Determine If You Need Buffer or Barrier Protection

Buffer systems (unpressurized) use Plan 52. The outer seal runs at atmospheric pressure. If the primary seal leaks, process fluid enters the buffer reservoir instead of escaping to atmosphere. You’ll know about the leak because reservoir level rises and fluid characteristics change.

Barrier systems (pressurized) use Plans 53A, 53B, 53C, or 54. Barrier fluid pressure exceeds seal chamber pressure. Any leakage flows into the process, not out. The atmosphere never sees process fluid.

The key question: Can you tolerate any process leakage to atmosphere?

If the answer is no – truly toxic materials, strict environmental requirements, or regulatory mandates – you need barrier protection. Buffer won’t cut it.

Step 2: Select the Appropriate Unpressurized Plan – Plan 52

Plan 52 works well for many VOC services and low-emissions applications. It’s simpler and cheaper than pressurized alternatives.

How it works: An external reservoir holds buffer fluid. A pumping ring in the outer seal circulates this fluid through the reservoir and back. When the pump stops, thermosyphon effect maintains slow circulation.

Critical setup requirement: The reservoir MUST vent to a flare or vapor collection system. If it’s sealed, pressure can build up to match seal chamber pressure. At that point, the outer seal loses its pressure differential and fails.

Limitation: Plan 52 isn’t truly hermetic. If the primary seal leaks badly, process fluid contaminates the buffer. For genuinely toxic applications, don’t rely on Plan 52.

Step 3: Select the Right Pressurized Barrier Plan – Plan 53A, 53B, 53C, or 54

Pressurized barrier plans guarantee zero process emissions. Here’s how they differ:

| Plan | Pressure Source | Gas Absorption | Fluid Volume | Best Application |

|---|---|---|---|---|

| 53A | Nitrogen blanket on reservoir | Yes – possible | Large (full reservoir) | Standard toxic/hazardous services |

| 53B | Pre-charged bladder accumulator | None | Limited (bladder capacity) | When gas absorption causes problems |

| 53C | Piston accumulator | None | Limited | High-pressure applications (>200 psig) |

| 54 | External pump or pressure system | N/A | Continuous supply | Hot, heavily contaminated services |

Plan 53A is the industry workhorse. A nitrogen blanket pressurizes the barrier fluid reservoir. Simple, reliable, widely used. One consideration: nitrogen can absorb into some barrier fluids, creating problems with seal face lubrication.

Plan 53B solves the gas absorption issue. A bladder separates nitrogen from barrier fluid. The downside? Limited fluid volume. Most of the accumulator is gas, so you don’t have much barrier fluid capacity.

Plan 53C uses a piston instead of a bladder. It handles higher pressures and provides better pressure control. Reserve it for demanding applications where 53A or 53B can’t meet pressure requirements.

Plan 54 brings barrier fluid from an external source – another pump or a central pressure system. It’s the go-to choice for temperatures above 400°F where the heat load overwhelms a Plan 53 reservoir. The trade-off: you’re dependent on that external supply. If it fails, you lose barrier protection.

Quick Reference: Which Plan for Which Service?

Keep this table handy during bid evaluation. It covers 90% of applications.

Single Seal Applications

| Service Condition | Primary Plan | Alternative | Notes |

|---|---|---|---|

| Clean HC <150°C | Plan 11 | – | Default choice, 50-75% of applications |

| Clean HC 150-230°C | Plan 23 | Plan 21 | Plan 23 more efficient but fussier |

| Clean HC >230°C | Plan 21 + 62 | Plan 32 | Add quench for coking prevention |

| Vertical pump | Plan 13 or 14 | – | Never use Plan 11 alone |

| Dirty fluid with solids | Plan 31 | Plan 32 | Plan 31 needs 2x SG difference |

| Abrasive/corrosive fluid | Plan 32 | – | External flush mandatory |

| Boiler feed water | Plan 23 | – | Water needs maximum cooling |

| Crystallizing fluid | Plan 11 + 62 | Plan 32 + 62 | Steam quench prevents buildup |

Dual Seal Applications

| Service Condition | Primary Plan | Alternative | Notes |

|---|---|---|---|

| Low emissions/VOC | Plan 52 | – | Must vent reservoir to flare |

| Toxic/hazardous | Plan 53A | Plan 53B | 53B if gas absorption is concern |

| High pressure (>200 psig) | Plan 53C | Plan 54 | Piston accumulator handles pressure |

| Hot + contaminated | Plan 54 | – | External supply for heat load |

| Low specific gravity (<0.7) | Plan 52, 53, or 54 | – | Light fluids need dual seals |

| Coking service >350°F | Plan 53B + 62 | Plan 54 + 62 | Quench prevents atmospheric coking |

Conclusion

Selecting the right seal flush plan comes down to four questions:

- Is your fluid clean and cool enough for Plan 11? If yes, you’re done – it handles most applications.

- Do you need cooling? High temperatures push you toward Plan 21 or 23.

- Is your fluid the problem? Dirty, abrasive, or corrosive fluids need external flush (Plan 32).

- Can any leakage reach atmosphere? Toxic or hazardous fluids require dual seals with appropriate buffer (Plan 52) or barrier (Plan 53/54) protection.

For complex applications, work directly with your seal manufacturer. Show them your process data sheets and ask them to validate your flush plan selection. The best vendors will run calculations on heat load, flow requirements, and vapor margin. That collaboration costs nothing and prevents expensive mistakes.