Across the industry, 88% of plants outsource some or all of their maintenance operations. The surprising part is the reason: 44% cite existing supplier agreements as the primary driver. Not cost analysis. Not quality assessment. Inertia.

That default mindset costs plants real money. The in-house vs. outsource decision for mechanical seal repair deserves the same rigor you apply to any capital expenditure. Plants with sufficient repair volume and a willingness to invest in training can cut per-repair costs by 30% or more — but only if they evaluate the decision with actual data rather than habit.

The Decision Framework Most Plants Skip

The core question is not “should we repair in-house?” It is “do we have the volume and capability to justify it?”

Start with volume. A typical hydrocarbon processing facility with 2,500 pumps spends roughly $2.5 million per year on mechanical seals alone. At that scale, even a 10-15% cost reduction from in-house repairs translates to $250,000-$375,000 in annual savings. Smaller plants running fewer than 25 seal repairs per year rarely justify the overhead.

Next, examine your current outsourcing arrangement. Only 23% of maintenance tasks are actually outsourced across the average plant, despite 88% having outsourcing agreements. This gap reveals something important: most plants already do partial maintenance in-house without recognizing they could extend that capability to seal work.

Three criteria drive the decision:

- Annual repair volume. Above 50 seal repairs per year, the economics strongly favor building in-house capability for routine seals.

- Existing shop infrastructure. A clean workspace, basic measurement tools, and a lapping plate are the minimum. You do not need a dedicated seal shop to start.

- Workforce skill base. This is where most plants miscalculate. Forty percent cite lack of skills as the reason they outsource — but the skills gap is smaller than they assume.

True Cost Comparison

Seal repair costs range from 10% to 60% of new seal price, averaging around 50%. That number applies whether you repair in-house or outsource. The difference lies in the total cost surrounding that repair.

Outsourcing carries three hidden costs most buyers miss. First, management redundancy — you maintain internal staff to coordinate with the contractor, duplicating oversight roles. Second, loss of direct control — you cannot prioritize urgent jobs or adjust schedules on the fly when the work happens offsite. Third, knowledge erosion — in-house employees accumulate decades of plant-specific experience that contractors never match.

The Fluid Sealing Association’s life-cycle cost framework captures this well. Their analysis across six cost categories — operating costs, equipment maintenance, seal maintenance, downtime losses, environmental compliance, and energy — consistently shows that the lowest upfront option rarely delivers the lowest total cost. The same principle applies to repair sourcing: the cheapest per-invoice option is not the cheapest over time.

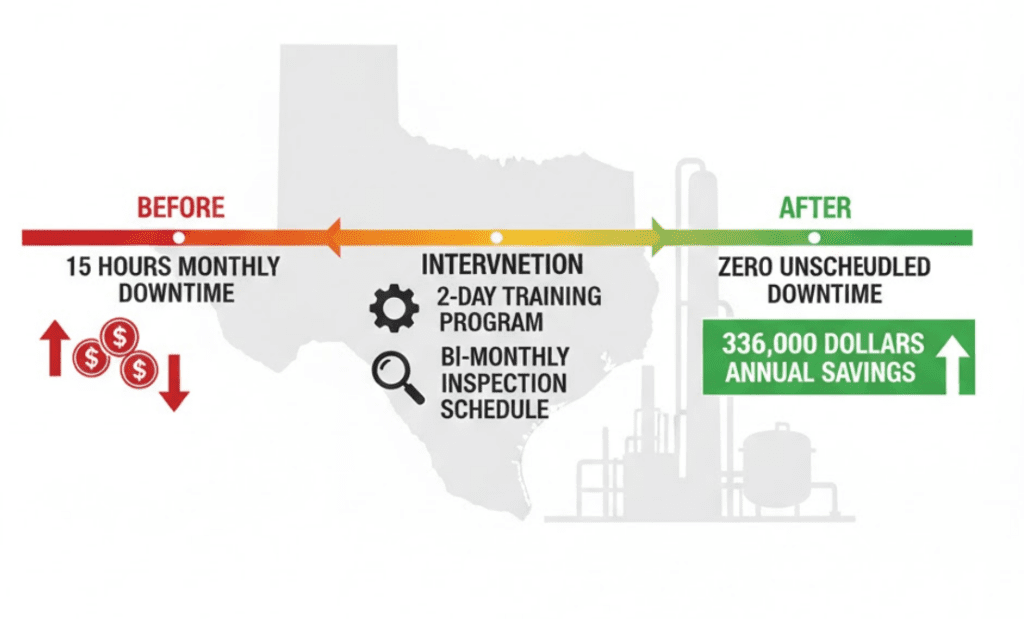

A SEPCO case study at a Texas chemical plant proved this. After years of recurring seal failures, the plant invested in a two-day staff training program and established bi-monthly inspections. Within three months, unscheduled downtime dropped to zero. Annual savings reached $336,000 — combining recovered production time, prevented product losses, and reduced maintenance costs. The total investment was a fraction of what they had been paying contractors.

Capability Requirements for In-House Repair

The real barrier to in-house seal repair is technique, not equipment. I have seen plants invest heavily in shop tooling only to achieve a 50% success rate on rebuilt seals. The seals leaked because technicians did not understand the fundamentals: surface finish requirements, contamination prevention, and proper compression settings.

Successful in-house programs share three characteristics:

Training comes first. A focused two-day program covering seal disassembly, inspection criteria, face lapping, and reassembly builds enough competence to handle routine single seals. The critical skills are not complex — keep seal faces mirror-smooth, prevent lubricant contamination of carbon or ceramic rings, and set compression square to the shaft.

Standard procedures exist. Document your repair process with go/no-go criteria at each step. A seal face with longitudinal scratches will leak regardless of how carefully you reassemble it. Clear rejection standards prevent wasted effort on seals that should be replaced.

Scope stays realistic. In-house programs work best for standard single seals and common cartridge configurations. Specialized dual seals, non-standard metallurgies, and seals from critical-service pumps demand capabilities most plants should not try to build.

Cartridge seal designs help bridge the skill gap. They reduce installation time by roughly 50% compared to component seals and eliminate on-site measurement errors. The 15-25% higher purchase cost pays for itself in reduced rework.

When Outsourcing Is the Right Call

Not every seal belongs in your shop. The hidden cost most buyers miss with in-house programs is overconfidence — attempting repairs beyond your team’s capability and suffering repeated failures that cost more than the outsourced alternative.

High-criticality seals warrant specialist attention. One synthetic fiber manufacturer running a Bornemann slurry pump at 120 PSI and 210F faced $15,000 per hour in downtime costs when their double cartridge seal failed. Gallagher Fluid Seals partnered with EagleBurgmann for a detailed examination and repair that doubled the seal’s service life. At that downtime rate, the premium for specialist repair paid for itself in under an hour of recovered production.

Outsource when any of these conditions apply:

- Equipment downtime exceeds $5,000 per hour, making first-time repair success critical.

- The seal involves exotic metallurgy, dual pressurized arrangements, or compliance requirements your team has not handled before.

- You lack root cause analysis capability — sending seals out for expert failure analysis, even if you repair routine seals yourself, prevents repeating the same mistakes.

The Hybrid Approach

The smartest maintenance programs treat the in-house vs. outsource question as a false binary. A tiered repair strategy handles routine seals internally while routing complex applications to specialists.

Tier your seal inventory by criticality. Routine single seals on non-critical water and utility pumps go to your in-house team. High-value or safety-critical seals — anything on reactor duty, hazardous service, or high-speed applications — go to a qualified specialist supplier with demonstrated competence on that seal type.

John Crane’s managed reliability programs demonstrate the value of this model at scale. Dedicated onsite engineers working against agreed KPIs achieved 50% fewer recurring equipment failures at one refinery. You do not need a contract that large to apply the principle. Even a small plant can split its seal population: build capability for the 70% of seals that are straightforward, and develop a relationship with one or two repair specialists for the remaining 30%.

When outsourcing complex seals, custom machined seal solutions address applications where standard replacements are unavailable — legacy equipment, discontinued models, or non-standard configurations that OEM channels no longer support.

Making the Right Choice

The repair sourcing decision comes down to honest self-assessment, not vendor promises. Plants running 50 or more seal repairs annually, with a clean workspace and trained personnel, will consistently spend less per repair in-house than outsourcing routine work. Plants handling fewer seals or lacking the commitment to proper training are better served by a good external partner.

Most facilities benefit from the hybrid approach: build in-house competence where volume justifies it, outsource where criticality demands it. The worst strategy — and the most common one — is defaulting to outsourcing without ever running the numbers.