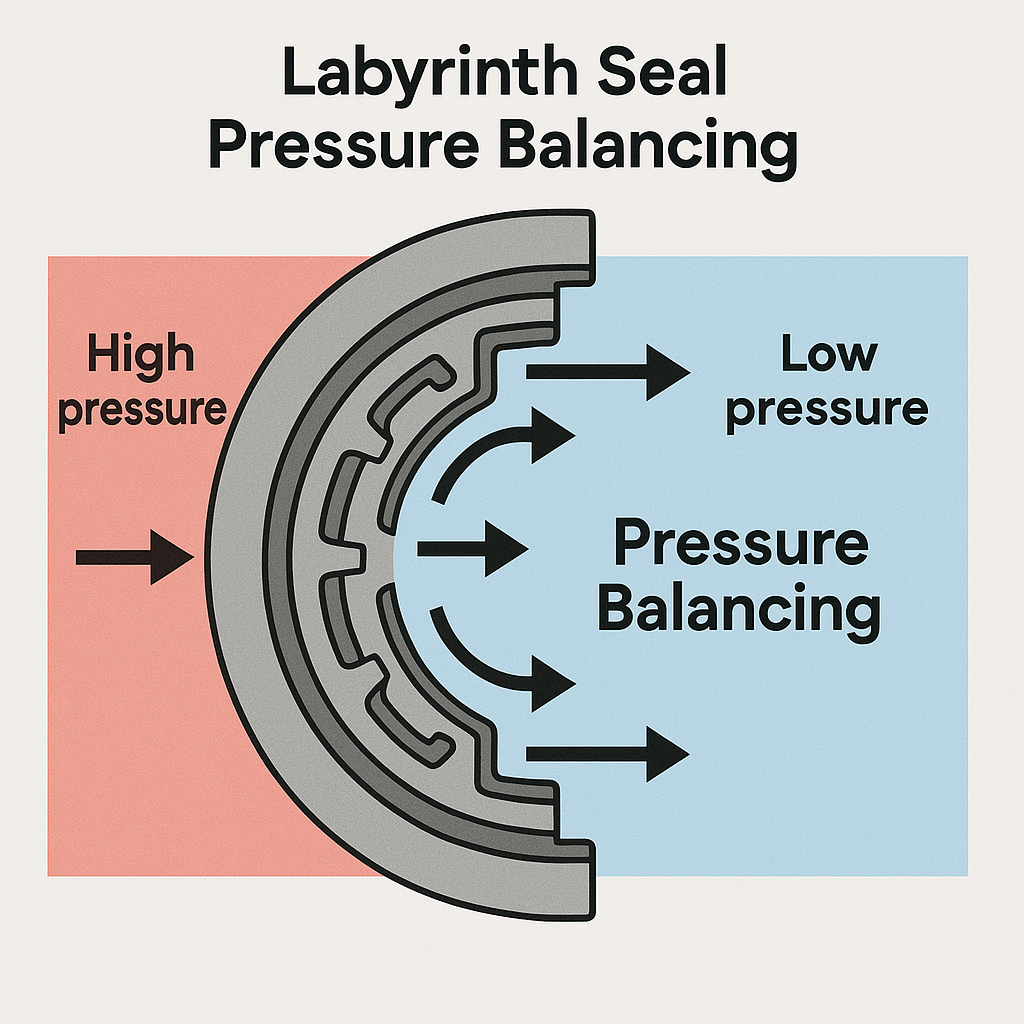

Labyrinth seals balance high pressure differences in turbines and compressors by breaking them into smaller, manageable steps. Instead of handling a massive pressure drop all at once, these seals use multiple sharp teeth and chambers to gradually reduce pressure while allowing minimal leakage. They’re the workhorses of turbomachinery because they’re simple, reliable, and can withstand extreme speeds and temperatures without wearing out.

Pressure Staging Mechanism

Labyrinth seals divide a large pressure drop into many smaller drops by forcing fluid through a series of narrow gaps under sharp teeth. Each tooth acts like a tiny throttle that speeds up the fluid and converts pressure into kinetic energy. Right after passing under a tooth, the fluid expands into a cavity where its speed dissipates as turbulence and heat.

This staged approach means no single tooth has to handle the entire pressure difference. The total pressure drop gets distributed across all the teeth, with each one taking a manageable portion. You end up with a series of pressure steps rather than one giant cliff.

The sum of all these individual pressure drops equals the total pressure difference the seal manages. It’s like going down stairs instead of jumping off a building – you get to the same place but much more safely.

Pressure Distribution and Load on Teeth

The pressure drop across a labyrinth seal isn’t perfectly even – the first tooth nearest the high-pressure side often takes the biggest hit. Sometimes a single tooth can experience almost half of the total pressure difference, which stresses that tooth and reduces its effectiveness. This uneven distribution is why designers add more teeth to spread the load.

With enough teeth, each one only needs to handle a small fraction of the total pressure. This protects individual teeth from excessive stress and makes the whole seal more durable. The staged drops also reduce the force pushing fluid through any given gap, effectively “balancing” the pressure in manageable increments.

Design Elements for Effective Pressure Reduction

- Number of Teeth: More teeth create more pressure drops and less leakage – it’s the single most important factor in seal performance. Studies show tooth count has a stronger influence on leakage than clearance or tooth size. You need enough teeth to safely distribute the pressure (typically 10-20 for high-pressure applications), but adding too many gives diminishing returns and takes up excessive space.

- Tooth Geometry: Sharp, thin, knife-like teeth work best because they promote flow separation and create larger vortices downstream. The tooth height and spacing (pitch) matter too – taller teeth create deeper cavities for better expansion, while closer spacing fits more teeth in a given length.

- Seal Clearance: The gap between tooth tips and the opposing surface dominates leakage performance – doubling the clearance can increase leakage by eight times. Typical clearances are just thousandths of an inch, with a rule of thumb being about 0.001″ clearance per inch of shaft diameter.

- Cavity Design: Wider and deeper cavities allow better flow expansion and larger recirculation vortices, which removes more kinetic energy. If cavities are too shallow, the high-velocity jet shoots through with minimal loss, reducing the next tooth’s effectiveness. Some designs include honeycomb linings or swirl brakes in cavities to increase turbulence and improve stability.

- Straight vs. Stepped Configuration: Stepped labyrinths (with alternating larger and smaller diameters) can reduce leakage by up to 30% compared to straight-through designs. They create asymmetrical cavities that induce extra turbulence and higher pressure drops per stage. Designers choose stepped seals when clearances must be larger or when handling extreme pressure ratios, though they’re more complex to manufacture.