Dry-running mechanical seals face extreme conditions that would destroy conventional materials in minutes. These seals must operate with little to no lubrication, generating intense friction and heat that can exceed 400°C. The right material selection determines whether your seal lasts years or fails catastrophically.

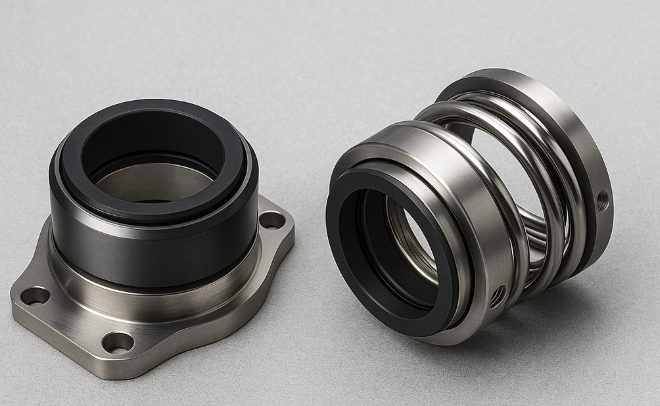

Two critical components need special materials: the seal faces (which create the primary seal) and the secondary seals (O-rings and gaskets that prevent leakage around the assembly).

Seal Face Materials

Carbon-Graphite

Carbon-graphite is the workhorse material for dry-running seals because it creates its own lubrication. The graphite structure naturally shears along molecular layers, depositing a microscopic lubricating film on the opposing face during operation. This self-lubricating behavior means the seal essentially runs on a graphite-on-graphite interface rather than destructive metal-on-metal contact.

- Pure carbon-graphite needs enhancement to work effectively in seals. Manufacturers impregnate the porous carbon with resins, metals, or special additives to boost strength and temperature resistance. Resin-impregnated carbon handles temperatures up to 250°C and resists most chemicals, making it the standard choice for general applications.

- Metal-impregnated carbon, typically filled with antimony, performs even better in demanding conditions. The antimony filling increases thermal conductivity, helping dissipate heat that would otherwise destroy the seal. These grades can operate continuously at 370°C while maintaining their lubricating properties.

Silicon Carbide (SiC)

Silicon carbide has become the gold standard for hard seal faces in dry-running applications. Its extreme hardness (second only to diamond) and exceptional thermal conductivity allow it to survive conditions that crack other ceramics. SiC conducts heat away from the friction zone five times better than alumina, preventing the hot spots that cause seal failure.

Two main types serve different needs in seal applications.

- Reaction-bonded SiC contains 8-12% free silicon, which limits its chemical resistance to pH 4-11 but provides excellent wear characteristics.

- Direct-sintered SiC offers nearly 100% purity, resisting virtually all chemicals while maintaining superior strength.

The material’s main weakness is brittleness – rapid temperature changes can cause catastrophic cracking.

Engineers often pair SiC with carbon-graphite faces to create the ideal combination. The carbon provides lubrication while the SiC offers a hard, thermally conductive surface that resists wear and dissipates heat effectively.

Tungsten Carbide (WC)

Tungsten carbide brings mechanical toughness to seal faces where silicon carbide might crack. WC consists of tungsten carbide grains cemented with cobalt or nickel binder, creating a material that handles vibration and mechanical shock better than any ceramic. This toughness makes it valuable in pumps experiencing cavitation or intermittent operation.

The material cannot self-lubricate, making it unsuitable for hard-on-hard dry running. Tungsten carbide faces must always run against carbon-graphite to avoid destructive friction and galling. Even with proper pairing, WC generates more heat than SiC due to its higher friction coefficient with carbon.

WC remains popular in oil-lubricated services and moderate conditions where its toughness provides value. For truly dry or high-temperature applications, silicon carbide has largely replaced it.

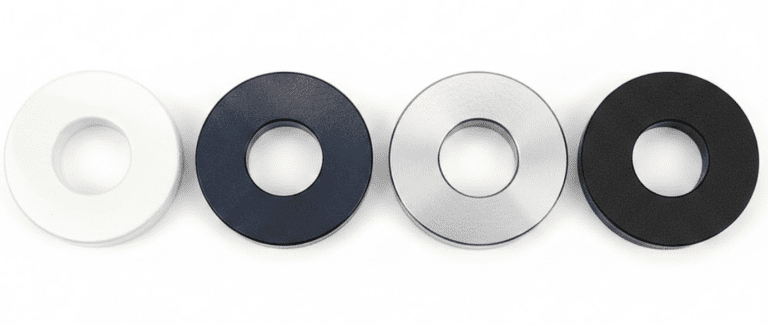

Elastomer O-Ring Materials

Ethylene Propylene Diene Monomer (EPDM)

EPDM excels in hot water and steam applications, maintaining flexibility up to 150°C with brief excursions to 180°C. The saturated polymer backbone resists ozone and weathering that destroys nitrile, making it suitable for exposed installations. Steam-quenched seals and caustic services particularly benefit from EPDM’s chemical resistance.

The material’s critical weakness is incompatibility with petroleum products. EPDM swells destructively in oils and hydrocarbon solvents, making it unsuitable for any oil-lubricated equipment. Even assembly lubricants must be silicone-based rather than petroleum-based.

Fluorocarbon (FKM, e.g. Viton®)

FKM elastomers have become the industry standard for demanding seal applications, combining 200°C continuous temperature rating with broad chemical resistance. Viton O-rings handle oils, fuels, acids, and most solvents while maintaining seal integrity at temperatures that destroy other rubbers. Low gas permeability makes FKM ideal for vacuum and gas seal applications.

But this material fails in hot water, steam, and strong bases, which cause rapid degradation. Amines and certain polar solvents also attack standard FKM grades.

Most dry-running seals specify FKM O-rings by default. The combination of heat resistance and chemical compatibility covers the majority of industrial applications, justifying the moderate cost premium over basic elastomers.

AFLAS (TFE/P copolymer)

AFLAS fills the gap where FKM fails, specifically in steam and amine services. This tetrafluoroethylene-propylene copolymer maintains stability at 200°C while resisting the bases and steam that destroy Viton. Oil and gas applications particularly value AFLAS for sour gas and ammonia resistance.

The material sacrifices some hydrocarbon resistance compared to FKM. Aromatic solvents and chlorinated compounds cause more swelling in AFLAS, limiting its use in some chemical processes.

Refinery seals exposed to high-pressure steam or amine corrosion inhibitors often specify AFLAS. The material costs more than standard FKM but less than perfluoroelastomers, providing a cost-effective solution for specific chemical challenges.

Perfluoroelastomer (FFKM, e.g. Kalrez®)

Perfluoroelastomers represent the pinnacle of elastomer technology, surviving continuous temperatures up to 280°C (specialty grades to 330°C) while resisting virtually all chemicals. FFKM combines the chemical inertness of PTFE with true rubber elasticity, maintaining seal force at temperatures that carbonize other elastomers.

The material’s extraordinary properties come at extraordinary cost – often 10-50 times more expensive than FKM. Mechanical properties are slightly inferior to standard elastomers, requiring careful handling during installation.

FFKM becomes essential when nothing else survives. Hot chlorine compressors, aggressive vacuum processes, and semiconductor manufacturing all require FFKM’s unique combination of temperature and chemical resistance.

Non-Elastomer Secondary Seals

PTFE O-Rings / Encapsulated O-Rings

PTFE offers universal chemical resistance and operates continuously at 232°C, but lacks the elasticity required for dynamic sealing. Pure PTFE O-rings work only in static applications where they can be mechanically compressed. The material’s tendency to cold-flow under load causes gradual seal degradation.

Encapsulated O-rings solve the elasticity problem by wrapping a PTFE sheath around a rubber core. This design provides chemical resistance on the wetted surface while maintaining elastic recovery. The PTFE jacket protects the core from aggressive chemicals that would destroy exposed elastomers.

These hybrid seals serve critical roles in ultra-corrosive applications. Fuming acids, strong oxidizers, and high-temperature oxygen services all benefit from PTFE’s inertness when elastomer options are exhausted.

Flexible Graphite (Graphite Foil)

Flexible graphite survives extreme temperatures that destroy all organic materials – up to 455°C in air and over 1000°C in inert atmospheres. Pure carbon composition provides immunity to virtually all chemicals except strong oxidizers at elevated temperatures. The material’s layered structure offers some self-lubrication, beneficial in dry-running conditions.

Graphite lacks elasticity entirely, requiring mechanical compression to maintain seal force. The brittle sheets crack easily during handling and can extrude under high pressure without proper support. Installation requires experienced technicians and specialized groove designs.

High-temperature mechanical seals above 250°C invariably use flexible graphite for secondary sealing. API 682 Category III seals specify graphite when elastomers would carbonize. Power plants and refineries rely on graphite’s temperature resistance for boiler feed pumps and hot oil services.

Metal Bellows

Metal bellows eliminate dynamic O-rings entirely, using welded metal convolutions to provide both spring force and sealing. This all-metal construction survives extreme temperatures and aggressive chemicals that destroy any soft seal. The bellows flexes axially while maintaining a hermetic seal, avoiding the stick-slip problems of dynamic O-rings in dry conditions.

FAQs

What’s the best seal face combination for completely dry running?

Carbon-graphite running against silicon carbide provides the optimal combination for dry conditions. The carbon deposits a lubricating film while the SiC dissipates heat effectively, allowing continuous operation without liquid lubrication.

How hot can dry-running seals operate?

Standard carbon/SiC combinations operate up to 370°C, while specialized materials like graphite-loaded SiC or diamond coatings can exceed 400°C. Secondary seal materials typically limit maximum temperature, with FFKM elastomers reaching 330°C and flexible graphite surviving over 450°C.

Why do O-rings fail in dry-running seals?

O-rings fail from thermal degradation when frictional heat exceeds their temperature rating. Standard nitrile hardens above 120°C, while even high-performance FKM elastomers carbonize beyond 230°C without proper heat management.

Can two hard faces run together dry?

Conventional hard face pairs like SiC-on-SiC fail quickly without lubrication due to extreme friction. Graphite-loaded silicon carbide enables hard-hard combinations by incorporating lubricating graphite particles within the ceramic matrix.

What’s the most economical material combination for occasional dry running?

Resin-impregnated carbon against reaction-bonded silicon carbide with FKM O-rings provides good dry-running tolerance at moderate cost. This combination handles intermittent dry conditions in most industrial applications without premium materials.