Yes, you can upgrade from gland packing to a mechanical seal, but only in some cases. Success depends on your specific equipment, operating conditions, and application requirements. Not every pump is a good candidate, and not every situation justifies the investment.

Why Upgrade?

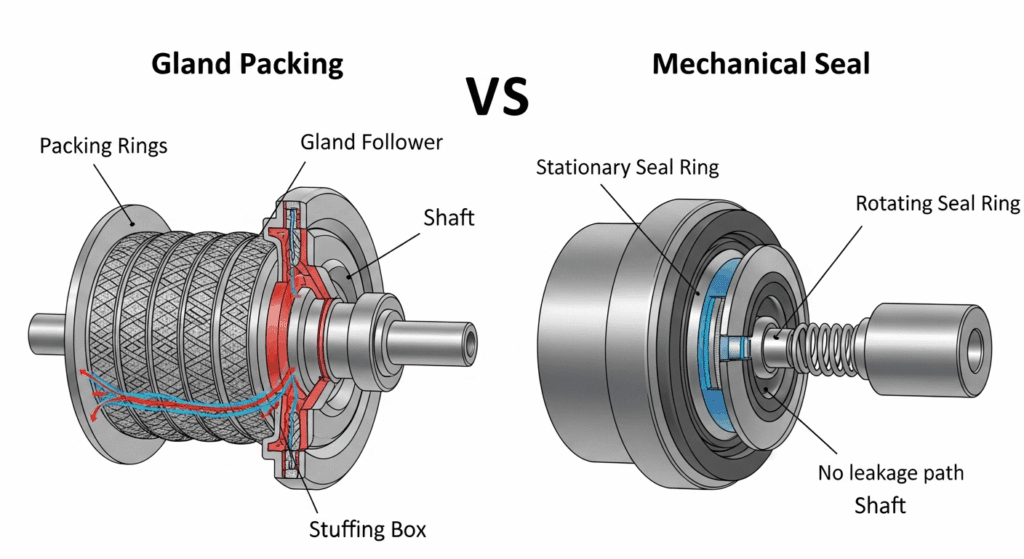

Dramatically Lower Leakage

Mechanical seals leak so little that the leakage is often visually undetectable. With gland packing, you’ll see a steady drip of fluid around the shaft—this is normal operation, but it adds up to significant product loss over time.

Significant Energy Savings

Mechanical seals require 80% less power to operate compared to gland packing. The friction between the rotating and stationary seal faces is minimal, while packing creates substantial friction as the shaft rotates against compressed material.

Reduced Maintenance and Labor

Gland packing requires regular readjustment and replacement—typically every 12-24 months depending on operating conditions. This means recurring service visits, equipment downtime, and skilled labor costs.

Mechanical seals, once properly installed, require no maintenance. They can run for 10+ years without adjustment or replacement in many applications.

Better Environmental and Safety Protection

Leaking gland packing contaminates nearby bearings and motor components, leading to premature failures and unplanned downtime. For hazardous fluids, packing leaks pose safety risks and environmental compliance issues.

Mechanical seals confine fluid completely, protecting equipment, personnel, and the environment. For critical applications (toxic chemicals, flammable liquids), this advantage alone often justifies the upgrade.

Extended Equipment Life

The bearing contamination caused by packing leaks is one of the biggest hidden costs of traditional sealing. Mechanical seals prevent this damage, extending your pump and motor lifespan significantly.

When NOT to Upgrade

Fire Pumps and Critical Safety Systems

Fire pumps and other emergency equipment prioritize availability over perfection. If a mechanical seal fails, it can require hours of diagnosis and replacement work. If gland packing fails, you simply tighten it slightly while the pump continues running.

In these safety-critical applications, the ability to maintain partial sealing under degraded conditions outweighs the efficiency advantages of mechanical seals.

Equipment with High Shaft Movements

Mechanical seals tolerate very little shaft movement—typically less than 0.5 millimeters of axial displacement. Mining pumps, slurry processors, and large ore handling equipment experience significant shaft deflection and misalignment due to their size and operating conditions.

Gland packing adapts to these movements and maintains its seal. Mechanical seals in these conditions fail quickly.

Abrasive and Dirty Fluid Applications

Gland packing tolerates abrasive slurries and dirty fluids far better than mechanical seals. The packing material itself can trap particles, while mechanical seal faces are sensitive to even small contamination.

In large slurry pumps and ore processing equipment, gland packing remains the standard choice because it’s more forgiving and robust than mechanical seals.

Budget-Constrained Operations with Skilled Maintenance Staff

Mechanical seals cost 3-5 times more upfront than gland packing. If your operation has limited budget for capital improvements but maintains skilled technicians experienced in packing maintenance, the lower upfront cost of packing may be the practical choice.

Over the long term, mechanical seals usually cost less. But if you can only afford the immediate expense, packing is the realistic option.

Poor Equipment Condition

Mechanical seals demand precision installation and excellent equipment condition. If your pump has a worn shaft, chronic misalignment problems, bearing wear, or vibration issues, installing a mechanical seal will likely fail.

Gland packing tolerates imperfect equipment much more readily. In these situations, fix the underlying equipment problems first, or upgrade to mechanical seals later when conditions improve.

Step-by-Step Evaluation Process Before Upgrading

Step 1: Assess Your Current Operating Conditions

Compile specific data about your pump’s current operation: continuous or intermittent running, typical operating temperature, system pressure, pump speed (RPM), fluid type, and maintenance history over the past 12-24 months.

This baseline data helps you identify if your operating conditions are suitable for mechanical seals and estimate the current cost of packing maintenance.

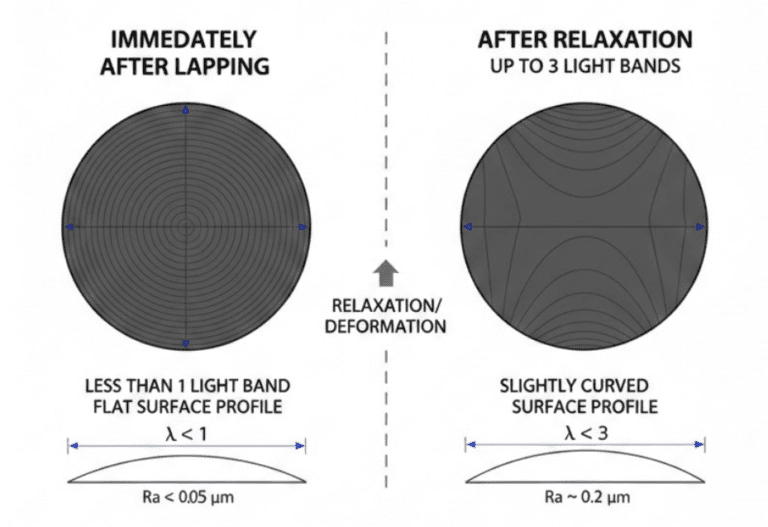

Step 2: Evaluate Equipment Condition

Inspect the pump shaft for wear, scoring, or rust. Check pump-to-motor alignment using a dial indicator (ideal is less than 0.1 millimeter runout). Listen for abnormal vibration or grinding sounds during operation.

Equipment in poor condition—worn shafts, misalignment, vibration—will cause mechanical seal failure. If you find problems, note whether they can be corrected before upgrade or if they disqualify the pump.

Step 3: Determine if Your Pump Housing Can Be Adapted

Examine your pump’s gland pocket where the packing is currently installed. Mechanical seals require a different physical footprint and installation space.

Most standard centrifugal pumps can accommodate mechanical seals without housing modifications. Some older pumps or specialty designs may require modifications to the seal cavity, adding cost and complexity to the project.

Step 4: Calculate True Cost of Ownership

Create a spreadsheet comparing five-year costs: current packing replacement and labor, product loss due to leakage, estimated bearing damage and replacement, energy costs, and downtime expenses. Then compare this to the mechanical seal upgrade cost plus five years of minimal maintenance.

Include a realistic estimate of when you’d need to replace the mechanical seal (typically 8-12 years, but later if conditions are ideal).

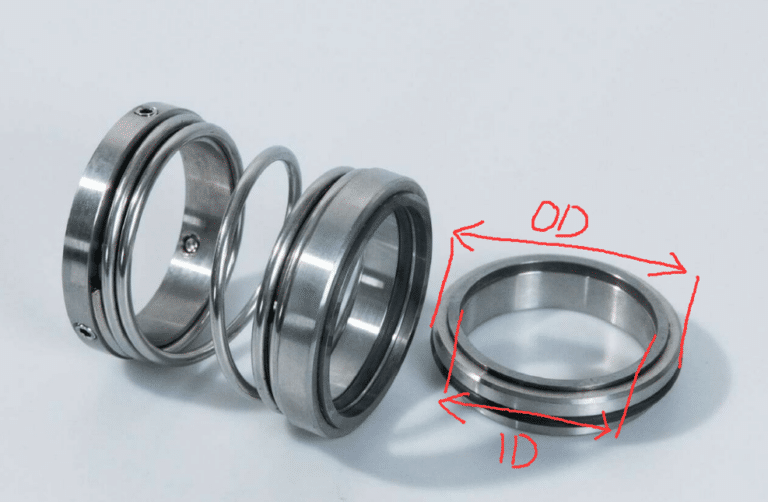

Step 5: Select Appropriate Seal Type and Materials

Single cartridge seals work well for clean liquids with moderate operating conditions. Double cartridge seals are necessary for hazardous fluids or non-lubricating process media. The seal material (carbon, ceramic, or silicon carbide) depends on your fluid type and operating temperature.

This selection requires understanding your specific application. Work with a seal supplier who can match equipment specifications to seal design.

Step 6: Plan Professional Installation

Contact experienced seal suppliers or pump service providers in your area to assess your specific pump and provide installation quotes.

A good supplier will inspect your equipment, identify any modifications needed, and provide a guarantee on the installation work.

Step 7: Establish Baseline Monitoring and Verification

After installation, monitor the upgraded seal during the first 30 days: check for any visible leakage (should be zero or near-zero), measure temperature near the seal chamber, and listen for unusual sounds.

FAQs

Can a non-expert install a mechanical seal?

Professional installation is strongly recommended. Improper installation is the most common cause of mechanical seal failure. Many seal suppliers offer installation guarantees only when trained technicians perform the work.

What’s the typical cost range for an upgrade?

Expect $1,300-$4,500 total cost: $800-$2,500 for the seal itself, plus $500-$2,000 for professional installation labor, depending on equipment complexity and local labor rates.