Dry gas seals fail far more often than most operators realize. About 48% of centrifugal compressor failures trace directly to seal problems, making them the single biggest cause of unexpected downtime in petrochemical plants, refineries, and pipeline operations.

Here’s the thing: most seal failures don’t happen suddenly. They develop over time, and operators who know what to watch for can catch problems early. This guide explains the nine most common failure modes so you can recognize trouble before it shuts down your equipment.

The Nine Most Common Dry Gas Seal Failure Modes

1. Contamination

Contamination causes 80% of dry gas seal failures. That’s not speculation—that’s what every industry study confirms.

Here’s what happens: particles smaller than 3 microns from your compressor casing get into the seal gas supply. These microscopic contaminants enter the thin gas film between your seal faces and plug up the grooves. Once the grooves are blocked, the seal can’t maintain its lifting force, and the rotating and stationary faces touch directly.

When those faces make contact, friction generates heat instantly. That heat deforms the seal rings, creates small cracks, and causes catastrophic failure within hours.

2. Condensation and Moisture Issues

Moisture in your seal gas creates one of the most destructive failure modes because it happens quietly while you’re not watching.

When seal gas pressure drops as it travels through your system, the gas cools. If the gas temperature falls below its dew point, water condenses. That condensate lands on your hot seal faces and blisters them. The blistering cracks your seal ring surfaces, which then collect more contamination, which accelerates failure.

This is particularly dangerous because the first sign of trouble—small blistering—looks minor. But within a few days, the damage compounds and your seal fails completely.

3. Low Seal Gas Pressure During Startup

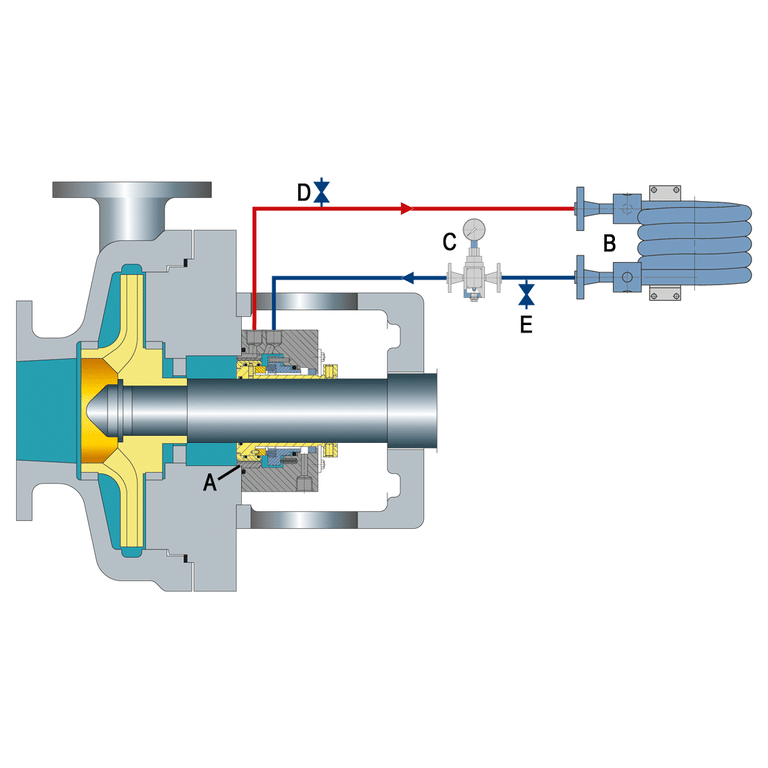

The first 30 minutes after you start a compressor are when most seal failures begin. Low seal gas pressure during startup lets dirty process gas flow backward into your seal cavity.

Here’s the sequence: you start the compressor, but seal gas pressure is slow to build. For those critical early minutes, pressure inside the compressor is higher than seal gas pressure. Process gas pushes backward through the seal cavity, contaminating your primary seal. By the time pressure normalizes 15 minutes later, the seal is already degraded.

Many operators don’t realize that low startup pressure causes problems because the compressor seems to run fine for hours afterward. But the damage is done—that contamination will cause failure within days or weeks.

4. Reverse Pressurization

Reverse pressurization happens when pressure on the downstream side of your seal becomes higher than the supply pressure on the upstream side. When that occurs, dirty process gas forces its way backward through the seal and contaminates everything.

Most operators don’t think about what happens during unusual operating conditions. If a flare system backs up, or if downstream equipment creates back pressure, or if your check valve fails, suddenly your seal sees pressure from the wrong direction.

5. Oil Migration from Bearing Lubrication

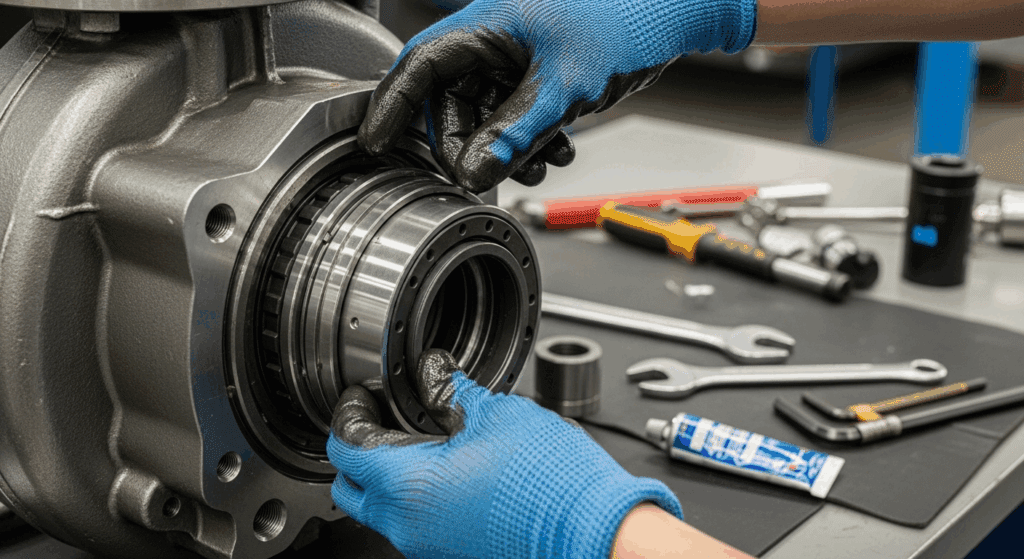

Bearing lubrication oil contaminating your seal is a slow poison. It starts with small amounts seeping through the barrier seal, gradually builds up, and eventually ruins your primary seal.

The barrier seal sits between your bearing oil and your dry gas seal. Its job is to keep oil out. But if something goes wrong—if pressure relationships shift, if an O-ring deteriorates, if the barrier seal develops a leak—oil creeps into the seal cavity. Once oil mixes with your seal gas, it coats the seal faces and destroys their ability to maintain the gas film.

6. Pressurized Hold (Settle-Out Condition)

This failure mode is sneaky because it happens during normal operation when your compressor is just sitting there, pressurized but not rotating.

When your compressor shuts down but the casing stays pressurized (because the suction valve didn’t close, or the recycle valve didn’t open, or you’re holding pressure for some other reason), your process gas just sits in there. With no shaft rotation and no seal gas flow, there’s nothing pushing process gas away from your seal cavity. Process gas slowly flows backward through the process labyrinth and into your primary seal.

That contamination sits there during the entire hold period. When you restart the compressor the next day, that degraded seal either fails immediately or within hours.

7. Explosive Decompression

Explosive decompression is what it sounds like: rapid pressure drop that causes catastrophic failure within seconds.

This usually happens because someone didn’t follow proper decompression procedure. Instead of slowly depressurizing through a relief valve over several minutes, the system loses pressure suddenly. The O-rings that seal your rotating and stationary components can’t flex fast enough for that pressure change. They extrude—push out of their grooves—and you lose all sealing capability instantly.

8. Misalignment

Misalignment forces your rotating and stationary seal faces to make uneven contact, concentrating all the force on one edge of the seal.

Think of it like pressing the edge of a piece of paper against another piece of paper instead of pressing face-to-face. You get high contact pressure on that edge, extreme heat generates, and failure happens quickly. Misalignment can develop over time as the compressor expands from heat or as equipment settles.

9. Reverse Rotation on Shutdown

When your compressor shuts down, the shaft should stop rotating immediately. If it doesn’t—if the suction valve stuck open or the recycle valve failed to open—your compressor keeps rotating backward due to pressure inside.

That reverse rotation forces gas backward through the grooved surfaces of your seal. The grooves are designed to work in only one direction. Backward flow actually pulls gas away from the seal cavity instead of pushing it in. That pressure loss causes contact between rotating and stationary faces, instant heat generation, and failure.