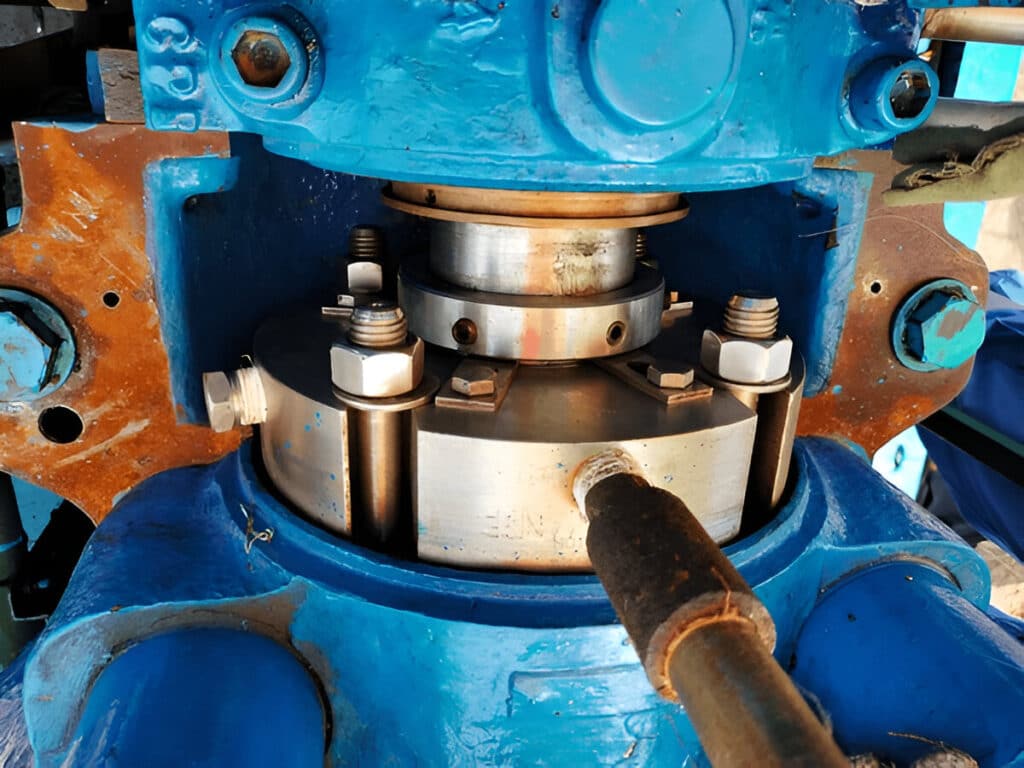

Mechanical seals prevent fluid from leaking out of pumps in industrial facilities. They’re the seal between the rotating shaft and the stationary pump housing, using precision-machined faces that press together to stop leaks.

This seal sits at the heart of your pump operation. When it fails, you face an immediate decision: repair the existing seal or replace it with a new one.

The cost difference matters more than you think. A simple repair might run 10-20% of the seal’s original price, while replacement costs vary from hundreds to thousands of dollars depending on the seal type. But the real expense often hides in downtime, lost production, and emergency labor rates.

How Much Does Mechanical Seal Repair Cost?

Mechanical seal repair costs range from 10% to 60% of the original seal price, depending on what needs fixing. The final bill depends on which components failed and how extensive the damage is.

Types of Repairs and Cost Ranges

Simple repairs cost the least because they only replace wear items.

- O-ring and gasket replacement: 10-20% of the seal’s initial price. These elastomer components wear out from heat, chemical exposure, and age. Most facilities replace them during routine maintenance before they fail.

- Face re-lapping: 30-40% of the original seal cost. The seal faces develop minor scratches and surface imperfections over time. Re-lapping restores the mirror-smooth finish needed for proper sealing.

- Face replacement and shaft sleeve refurbishment: 40-60% of the original seal price. Deep scoring, cracks, or material loss on the seal faces requires complete component replacement. Shaft sleeve damage adds to the repair scope and cost.

These percentages apply to the seal’s purchase price, not its replacement cost. A dual mechanical seal originally priced at $3,000 might need $900 to $1,800 in repairs for extensive work.

The repair bill also includes labor. Simple O-ring replacement might take one hour. Extensive repairs involving face replacement and seal reconditioning can require several hours of skilled technician time at $50-$75 per hour.

Which Seals Can Be Repaired?

Component seals offer more repair options than cartridge seals because you can access individual parts.

Component seals bolt together from separate pieces. You can replace faces, springs, O-rings, and sleeves individually. This design makes them ideal candidates for repair when only specific parts show wear.

Cartridge seals come pre-assembled as complete units. The manufacturer sets all tolerances and alignments at the factory. While you can repair some cartridge seal designs, the modular nature often makes replacement more practical. Cartridge seals reduce maintenance time by 60% compared to component seals, saving $1,000-$2,000 in labor costs per change-out.

What factors affect the repairability?

Material type affects repairability. Silicon carbide and tungsten carbide faces can be re-lapped if damage is minor. Carbon faces typically can’t be repaired and require replacement. Certain exotic materials used in chemical service have limited repair options.

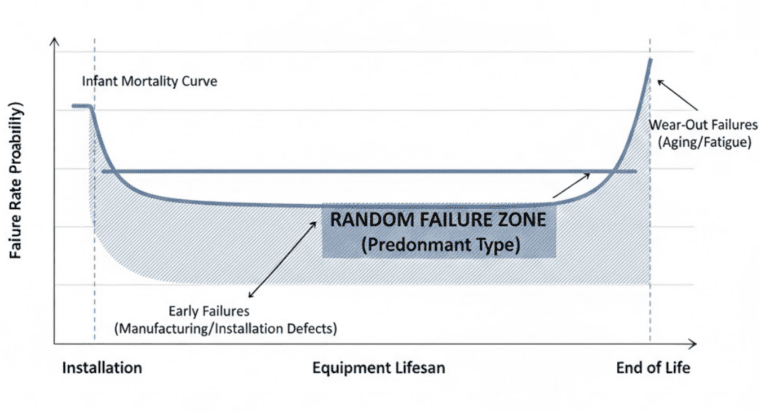

Seal age and condition determine whether repair makes sense. A seal with five years of service life remaining is worth repairing. A seal nearing the end of its design life should be replaced, not patched.

High-quality seals from major manufacturers repair better than budget models. Premium seals use tighter tolerances and better materials. These characteristics mean repairs can truly restore like-new performance.

When Should You Repair vs Replace a Mechanical Seal?

Replace the mechanical seal when repair costs exceed 50% of a new seal’s price. This industry-standard threshold helps you avoid spending repair money on a seal that won’t deliver reliable long-term performance.

The 50 Percent Rule

The 50 percent rule provides a clear decision framework for maintenance managers facing seal failures. If your repair estimate costs less than half of what a new seal would cost, repair makes financial sense. If repairs cost more than 50% of replacement price, you’re better off installing a new seal.

Calculate the rule correctly by comparing total costs, not just part prices. Add the seal price, labor hours, shipping, and expected downtime for both scenarios. A $2,000 repair on a seal with a $3,500 replacement cost crosses the 50% threshold at 57%.

Repair When

Repair makes sense when the seal can return to reliable service at reasonable cost.

- Damage is minor or localized: Small chips on the seal face, worn O-rings, or surface scratches respond well to repair. The seal’s core structure remains sound.

- Seal can be returned to like-new condition: Many seal designs can have faces re-lapped and elastomers renewed to restore full performance. This works best on high-quality seals built to tight tolerances.

- Cost stays under 50% of replacement: Keep total repair costs below half of what a new seal would cost, including parts, labor, shipping, and downtime.

- High-quality or custom seals with long remaining life: Specialty seals designed for your specific application are worth repairing. Custom seals with long lead times should be repaired rather than waiting months for a replacement.

- Quick turnaround is possible: Repair facilities can often complete work in one to two weeks. Some shops offer emergency repair service for critical seals.

Replace When

Replacement becomes necessary when repair can’t restore reliable operation or costs approach new seal prices.

- Cracks, warps, or extensive material loss: Structural damage to the seal housing, severe face scoring, or metal erosion can’t be repaired. These conditions compromise the seal’s integrity.

- Repeated failures despite multiple repairs: A seal that fails every three to six months despite proper repairs signals a deeper problem. Replacement with an upgraded design solves chronic issues.

- Seal is outdated or doesn’t meet current standards: Older seal designs may not comply with current API 682 standards, which aim for minimum three-year service life. Modern seals offer better performance and reliability.

- Operating conditions have changed: Pumps moved to more demanding service, higher temperatures, or corrosive fluids need seals designed for those conditions. Your original seal can’t be upgraded to handle the new requirements.

- Persistent leakage continues: Continuous leakage after proper repair and installation indicates the seal can’t handle your application. Material compatibility or design issues require a different seal type.

- Visible damage to seal faces: Deep scoring, cracks, or chips in the sealing surfaces prevent proper sealing. Re-lapping can’t fix damage that extends beyond the surface layer.

Red Flags Requiring Immediate Replacement

Certain failure symptoms tell you replacement is the only safe option.

- Continuous or excessive leakage: Heavy leakage indicates worn seal faces, failed elastomers, or improper installation that can’t be corrected with repair. This poses safety and environmental risks in chemical plants, water treatment facilities, and food processing lines.

- Cracks, chips, or scoring on seal faces: Surface damage visible to the naked eye means the seal faces can’t maintain the contact needed for sealing. These defects grow worse under operating conditions.

- High operating temperatures indicating failure: Elevated seal chamber temperatures point to dry running, poor lubrication, or friction from misalignment. The heat damages elastomers and can warp metal components beyond repair.

- Multiple previous repair attempts: A seal repaired twice that fails a third time should be replaced. The pattern indicates fundamental problems that repairs can’t solve. Each failure increases downtime costs that quickly exceed replacement expense.

FAQs

How long do mechanical seals typically last?

Mechanical seals typically last three to five years in properly maintained pump systems. The API 682 standard, published in 1994, sets a minimum three-year uninterrupted service life as the industry benchmark for quality seal designs.

Actual lifespan varies with operating conditions, fluid type, temperature, pressure, and maintenance practices. Seals in clean water service often exceed five years, while seals handling abrasive slurries or corrosive chemicals may need replacement sooner.

Should I keep spare seals in inventory?

Keep spare seals in inventory for critical pumps where downtime costs exceed seal storage costs. A $2,000 seal sitting on the shelf costs less than one day of lost production in most industrial facilities.

Stock spares for seals with long lead times, typically 8-12 weeks for specialty or custom designs. Common seals from major manufacturers often ship within days, making spare inventory less critical. Store spare seals in a clean, dry environment away from direct sunlight and heat sources to prevent elastomer degradation.

How do I choose between repair vendors?

Request quotes from at least two qualified seal repair vendors. Compare total costs including shipping both ways, turnaround time, warranty terms, and their experience with your specific seal brand and model.

Ask if they offer complimentary seal failure analysis. Many manufacturers provide free analysis on any seal brand to identify root causes. This service, typically completed in about two weeks, helps you understand whether repair or replacement makes more sense for your situation.