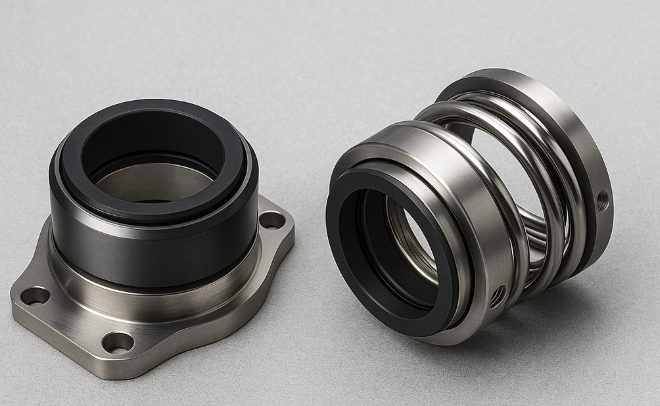

A mechanical seal bellows is a flexible component that prevents leakage while accommodating shaft movement and temperature changes in rotating equipment.

These bellows come in three main types: elastomer (rubber), metal, and PTFE (Teflon), each designed for specific operating conditions and applications.

Elastomer (Rubber) Bellows Mechanical Seals

Elastomer bellows provide excellent flexibility and sealing performance at moderate temperatures and pressures. These rubber-based components adapt well to shaft misalignment and vibration.

Different Types of Elastomer (Rubber) Bellows

- Nitrile (NBR) bellows work best with petroleum-based fluids and operate effectively between -40°F to 250°F. They dominate general-purpose sealing applications due to their low cost and good oil resistance.

- EPDM bellows excel in water, steam, and chemical services up to 300°F. They resist weathering and ozone but fail quickly when exposed to petroleum products.

- Viton (FKM) bellows handle aggressive chemicals and high temperatures up to 400°F. Industries choose them for demanding applications despite their higher cost.

- Silicone bellows maintain flexibility at extreme temperatures from -100°F to 450°F. Food and pharmaceutical industries prefer them for their non-toxic properties and FDA compliance.

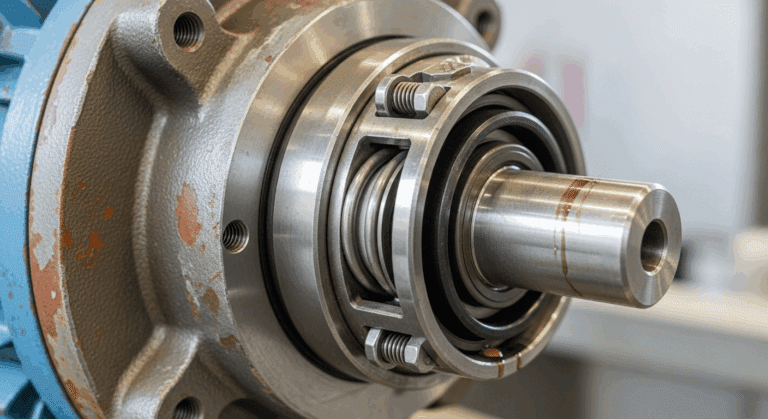

Metal Bellows Mechanical Seals

Metal bellows deliver superior performance in extreme temperature and pressure conditions. They eliminate the need for dynamic secondary seals, reducing potential leak paths.

These seals handle temperatures from cryogenic levels to over 800°F. Their welded or formed construction provides consistent spring force throughout the seal’s life.

Different Types of Metal Bellows

- Welded metal bellows use thin metal plates welded together to form convolutions. They provide maximum flexibility and longer stroke lengths for applications with significant axial movement.

- Edge-welded bellows join metal plates along their edges to form convolutions. This design handles higher pressures than other metal bellows types. Nuclear power plants often specify edge-welded bellows for critical sealing applications.

- Formed metal bellows are manufactured from a single piece of metal through hydroforming or mechanical forming. They offer greater pressure resistance but less flexibility than welded designs.

- AM350 stainless steel bellows combine corrosion resistance with high strength. They suit most chemical processing applications requiring metal bellows seals.

- Hastelloy bellows provide exceptional resistance to chlorides and acids. Chemical plants specify them for the most corrosive services where standard stainless steel fails.

- Inconel bellows maintain strength at extreme temperatures up to 1,800°F. Aerospace and power generation industries rely on them for high-temperature turbine applications.

PTFE (Teflon) Bellows Mechanical Seals

PTFE bellows offer universal chemical resistance and low friction properties. They bridge the gap between elastomer flexibility and metal bellows’ chemical resistance.

These seals work effectively from -100°F to 500°F in most chemical environments. Their non-stick surface prevents product buildup in crystallizing or polymerizing services.

Different Types of PTFE (Teflon) Bellows

- Virgin PTFE bellows provide the purest form with maximum chemical resistance. Pharmaceutical and semiconductor industries require them for ultra-clean applications.

- Filled PTFE bellows incorporate glass, carbon, or bronze fillers to improve wear resistance and reduce cold flow. They last longer in abrasive services than virgin PTFE.

- Modified PTFE bellows use special processing techniques to enhance flexibility and reduce permeation. They seal better against gases and volatile liquids than standard PTFE.

- Expanded PTFE bellows feature a microporous structure that increases conformability. They seal effectively on damaged or misaligned equipment where rigid bellows might leak.