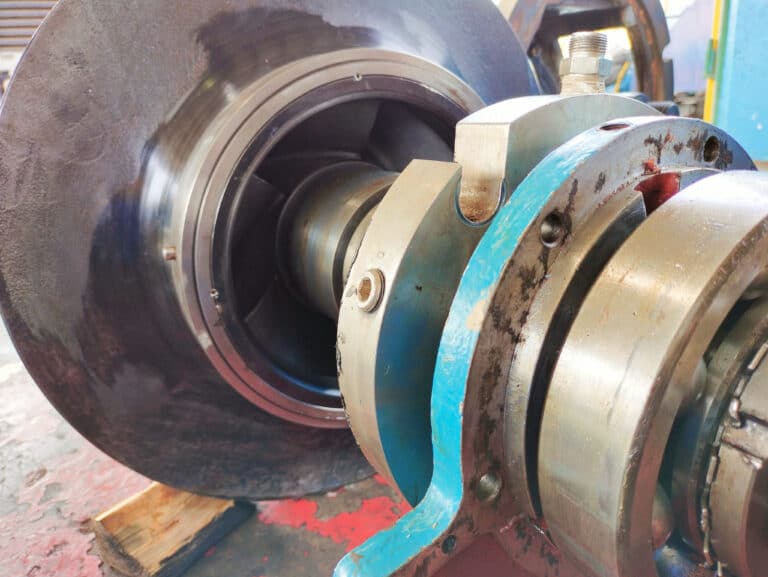

No, labyrinth mechanical seals don’t need lubrication to function properly. Unlike traditional contact seals that rely on a thin film of oil or grease to prevent wear, labyrinth seals work through a clever non-contact design that creates a tortuous path for fluids trying to escape.

Why Labyrinth Seals Don’t Require Lubrication

The non-contact design is the key to understanding why these seals run dry. Since nothing touches, there’s no friction to generate heat or cause wear that would need lubrication to prevent.

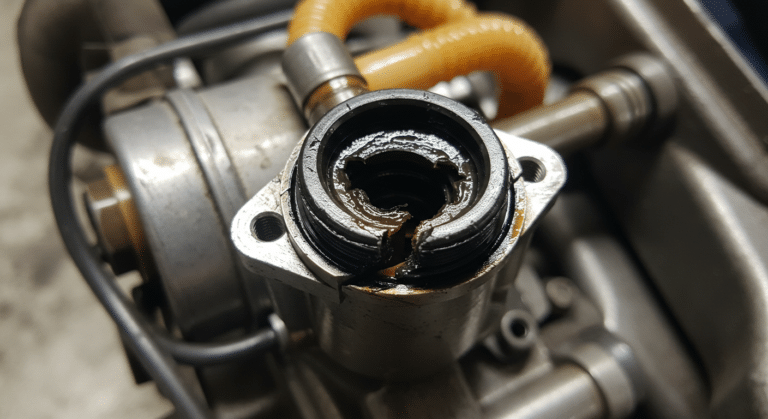

Traditional seals work like a rubber gasket pressed against a spinning shaft. Without oil, they’d quickly overheat and fail from the constant rubbing. Labyrinth seals sidestep this problem entirely.

The air or gas trapped in the seal’s chambers actually acts as its own barrier. As the shaft spins, it creates tiny vortexes in each chamber that help block the flow path even more effectively.

When You Might Consider Adding Lubrication

While labyrinth seals don’t need lubrication for their basic function, there are specific situations where you might add it anyway.

In extremely dusty environments, a light oil mist can help flush out particles that might accumulate in the seal chambers. This isn’t lubricating the seal itself but using oil as a cleaning agent.

Some applications use grease-packed labyrinths as a secondary barrier. The grease doesn’t lubricate moving parts but creates an additional obstacle for contaminants trying to enter the system.

Steam turbines sometimes inject sealing steam into labyrinth seals. Again, this isn’t lubrication but rather using steam pressure to prevent air from entering the system.