Your equipment’s reliability depends on a decision you might not even realize you’re making: what barrier gas should feed your dry gas seal? It sounds technical, but it’s really about preventing two expensive problems – process contamination and bearing oil leaks.

What is a Barrier Gas in Dry Gas Seals?

Barrier gas is pressurized gas—typically nitrogen or clean air—that you deliberately inject into the seal chamber at a pressure higher than your process fluid. Think of it as a protective buffer that stands between your process and your seal faces, preventing contamination from flowing backward into the equipment where it could cause damage.

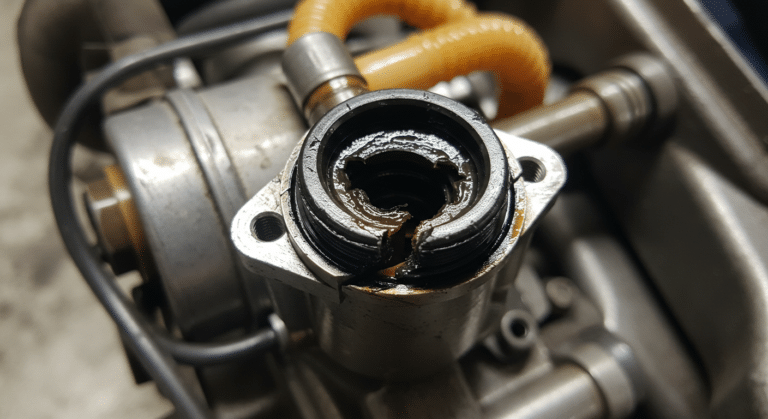

Here’s the basic setup: your dry gas seal has two main jobs to do. First, it needs to keep process fluid from leaking out. Second, it needs to prevent bearing oil from leaking in. Neither is optional. If process fluid touches the precision-ground seal faces, you’re looking at catastrophic failure. If bearing oil contaminates the seal chamber, the gas film that keeps the seal faces apart breaks down, and you’ve got face-to-face contact and rapid wear.

Barrier gas solves both problems at once. The pressurized gas creates a physical barrier that repels both the process fluid from above and the bearing oil from below. It’s like having a security guard standing between two doors, refusing entry to both. Without proper barrier gas, your seal is running blind and unprotected. With it, you’ve got a reliable defense against the two biggest threats to seal survival.

Nitrogen vs. Air: Which Should You Choose?

The two most common barrier gas options are nitrogen and clean air. Both work physically, but they’re not equally suitable for all applications, and your choice shapes your entire barrier gas system.

Nitrogen as Barrier Gas

Nitrogen is inert, meaning it doesn’t react with anything. It won’t combine with process chemicals, it won’t corrode seal materials, and it won’t create explosive mixtures with other gases in your system. That’s why nitrogen is the industry standard choice. Most plants that can access nitrogen use it without hesitation.

Nitrogen has zero chance of creating an explosive hazard. In applications where your process fluid is flammable or toxic, this matters enormously. Your vent line can discharge nitrogen safely into the atmosphere or a flare system without triggering fire alarms or safety concerns.

If you’re generating nitrogen on-site using PSA or membrane technology, you’ll get purity between 95-99.5%. This is clean enough for seal requirements and gives you a reliable, controlled supply. Most remote locations and high-volume users generate their own nitrogen specifically because it’s more economical than trucking it in.

Air as Barrier Gas

Clean air is tempting because it’s free if you’ve got a compressor on-site. You might think “why pay for nitrogen when I’ve got compressed air right here?” The answer is safety and regulations.

Air becomes explosive when mixed with certain gases and hydrocarbons in the right concentrations. If your process fluid contains hydrocarbons or your vent line connects to a flare system, using air as barrier gas can create an explosive mixture. API standards explicitly restrict air use in certain applications because of this risk.

Air also contains moisture and particles that nitrogen-only systems might not have. You’d need more aggressive drying and filtration to use air safely, which adds cost and maintenance complexity.

Decision Matrix: Nitrogen vs. Air

Use nitrogen if:

- Your process involves flammable or toxic fluids

- Your vent line connects to a flare or enclosed system

- You need maximum safety margin with zero risk

- You’re in a hazardous area classification (Class I, Class II)

- Regulatory compliance is non-negotiable

Consider air only if:

- Your process is non-flammable and non-toxic

- You have reliable, high-quality compressed air on-site

- Your vent line discharges safely to atmosphere

- Your equipment isn’t in a hazardous area

- You’ve verified with your equipment OEM that air is acceptable

Honestly? Most plants default to nitrogen and call it done. It removes ambiguity and safety concerns. The cost difference is usually small compared to the reliability you gain.

Barrier Gas Selection Criteria: What to Consider

Choosing the right barrier gas isn’t just about nitrogen-versus-air. You need to think through several factors that define what your system needs to do.

Process Compatibility

Start by asking: what’s my process fluid? Is it clean or dirty? Is it wet or dry? Is it corrosive or toxic?

If your process is dirty—say, you’re pumping crude oil with sand and water content—you might prefer an outside barrier gas source. That way, if the main seal fails and process fluid leaks into the seal chamber, your barrier gas remains uncontaminated and can maintain emergency sealing until you shut down for maintenance. This is called an “external” barrier gas supply, and it’s specifically designed into API Plan 74 configurations for exactly this scenario.

If your process is clean and stable, you might use the discharge pressure from your compressor or pump as a barrier gas source. This saves the cost of a separate nitrogen supply, though it requires that the discharge be filtered and dried to meet barrier gas quality standards.

Pressure Requirements

Pressure is your seal’s lifeline. Set it too low and process fluid or bearing oil can breach your seal. Set it too high and you can damage the seal cartridge itself.

Your barrier gas pressure must always exceed your maximum process pressure. The minimum differential is 0.2 MPa (3 psi), but for critical equipment or hazardous fluids, jump to 1.7 BARG (25 PSIG). This larger margin gives you safety headroom if process pressure spikes unexpectedly.

Here’s what usually goes wrong: maintenance teams set the pressure regulator once during commissioning and never look at it again. Then the regulator drifts or gets dirty, pressure slowly creeps below specification, and one day you’ve got contamination in your seal. Set a monitoring routine. Check that gauge weekly, and audit your regulator annually.

Flow Rate Needs

Barrier gas flow rate is the amount of gas actually flowing through the system, measured in cubic feet per minute (CFM) or standard cubic meters per hour (Nm³/h). This is different from pressure.

You need minimum flow to keep the separation seal (the barrier between bearing oil and your seal chamber) functioning. Too little flow and bearing oil migrates into the seal chamber despite the barrier. Too much flow wastes energy and increases operating costs. Most equipment manufacturers specify the required flow range on your seal data sheet.

If you’re commissioning a new system, call your seal vendor and ask for the exact flow requirement. If you’re retrofitting or troubleshooting an existing system, check the original installation documentation. Guessing at flow rate is how you end up with premature seal failures.

Supply Source Availability

Can you get nitrogen at your site? How far is the nearest supplier? What’s your consumption rate?

For a small operation that uses barrier gas occasionally, buying nitrogen from a local gas distributor in cylinders makes sense. For a large facility running continuous process equipment, an on-site nitrogen generator pays for itself within 1-3 years through cost savings alone. Generators also eliminate supply chain risk—you’re never without nitrogen because you’re never dependent on a delivery truck.

Geography matters. Remote sites far from gas suppliers almost always justify on-site generation. Urban industrial areas with established gas distribution might find cylinder delivery cheaper. Calculate both options and compare total cost of ownership over 5-10 years.

Environmental and Safety Factors

Check your equipment classification. If you’re in a hazardous area (Class I Division 1, for example), your barrier gas system needs to comply with specific standards. Air as a barrier gas might be prohibited. Nitrogen becomes not just preferred but required.

Your vent line also drives the decision. Where does your barrier gas vent after passing through the seal? If it goes to a flare system or enclosed recovery system, you must use nitrogen. If it safely vents to atmosphere at your loading dock, air might work. But again, nitrogen eliminates the ambiguity.

Conclusion

Barrier gas selection is one of those decisions that feels obscure until something goes wrong, then suddenly becomes the most important thing you didn’t pay attention to. Nitrogen is the right choice for nearly every industrial application—safer, more reliable, and increasingly cost-effective with on-site generation.

Your real job is maintaining that barrier gas properly. Check pressure weekly. Keep filtration at spec. Drain your oil traps. Replace cartridges on schedule. These simple habits prevent 90% of barrier gas failures and extend your seal life to the full 15-year design life.

The small investment you make in barrier gas system design and maintenance pays dividends through higher equipment reliability, lower total cost of ownership, reduced emissions, and fewer emergency repairs that disrupt production. That’s not just good maintenance—it’s good business.