Your pool pump’s mechanical seal is like the heart of your circulation system. It relies on water flowing through it constantly for both cooling and lubrication. Stop that water, and the seal will fail in minutes.

When a pump runs without adequate water—called “dry running”—the friction between internal components skyrockets. The seal overheats and cracks almost instantly. What starts as a $300-400 repair (seal replacement) can turn into a $1,200-2,500 pump replacement if you don’t catch it fast.

Immediate Warning Signs (Listen & Watch)

You don’t need special tools to spot dry running. Your ears and eyes tell the story.

Unusual Noises

A pump running dry sounds angry. You’ll hear grinding, screeching, or squealing—not the normal quiet hum you’re used to.

These noises come from excessive friction as the seal deteriorates. The grinding “roar” of damaged bearings is especially distinctive and unmistakable. If you hear sudden weird sounds, shut the pump off immediately.

Burning Smell

The combination of an overheating motor and scorched pump seal creates a sharp, acrid smell. It smells like burning plastic or electrical insulation.

If you catch a whiff of this near your pump, dry running is almost certainly happening. The smell is strong enough that you’ll notice it even from several feet away.

Overheating

Feel the pump housing. A normal pump is warm to the touch. A pump running dry becomes extremely hot—hot enough to burn your hand if you’re not careful.

A pump can reach internal temperatures of 300-400°F within minutes without water to cool it down. If the pump is too hot to hold your hand on, stop running it immediately.

Sudden Loss of Water Flow or Pressure

Check your filter pressure gauge and return jets. Are they weaker than normal?

A pump that has run dry loses its prime or develops severely diminished flow. You’ll see low filter pressure, reduced water circulation, and possibly air bubbles in the pump basket or returns.

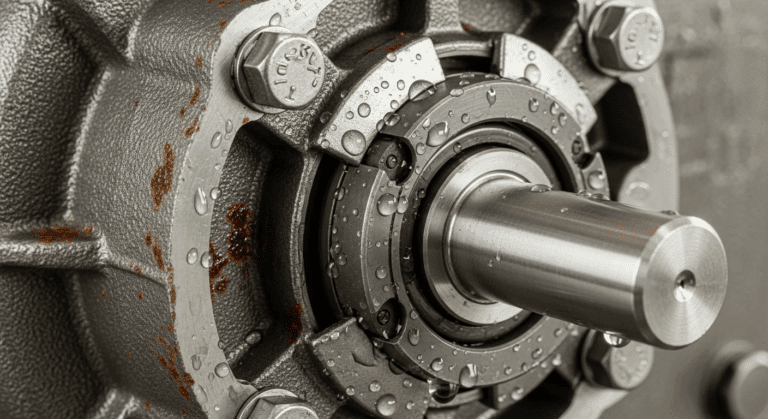

Physical Evidence of a Dry-Run Seal

After suspected dry running, these visible signs confirm the pump took damage.

Water Leaking From the Seal Plate

The seal plate is where the motor bolts to the pump housing. Look underneath—this is where a failed shaft seal always leaks.

Water trickles down the back of the seal plate and drips off the bottom. The leak point is distinctive: water coming from the underside center of the pump where the shaft connects (not from loose pipe fittings above).

Even a slow drip signals seal failure. If you see moisture there, replacement is needed.

Melted or Warped Plastic Components

Extreme heat warps plastic parts. Look at the pump basket, volute (housing), and PVC fittings attached to the pump.

Do they appear shrunken, distorted, blistered, or discolored? These are telltale signs the pump experienced severe overheating. Heat-damaged fittings often develop new air or water leaks, worsening the problem.

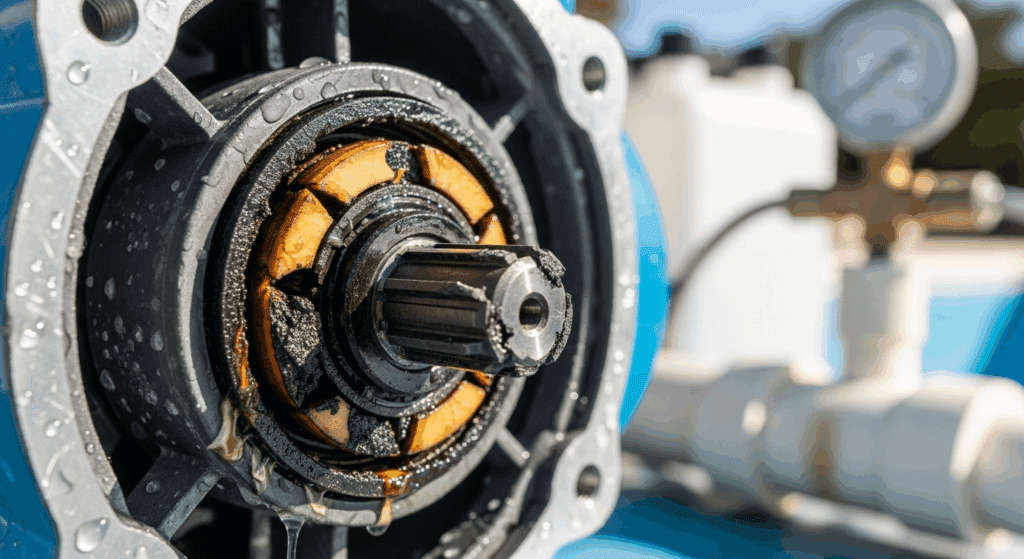

White Residue or Discoloration on Seal Faces

The mechanical seal has a polished ceramic face mated against a carbon face. When it overheats from dry running, the seal face turns white.

You’ll only see this if you disassemble the pump, but pool technicians use it as a diagnostic clue. Water that leaked into the motor leaves white calcium deposits and rust around the motor’s front end—dried mineral deposits from escaped water.

Seized or Stiff Pump Shaft

With the power off and after the pump cools, try gently rotating the motor shaft or impeller by hand.

A pump that ran dry may have a seized shaft or much more friction than normal. If the shaft won’t turn at all, the pump likely suffered significant internal damage from melted seal parts or heat-damaged bearings.

How to Diagnose a Dry-Run Problem

Don’t guess—follow these diagnostic steps to confirm what happened.

1. Shut Off the Pump Immediately

Never continue running a pump you suspect ran dry. Turn off the power right away.

Allow the system to cool for at least 20-30 minutes before touching anything. A pump can be hot enough to cause burns.

2. Check the Strainer Basket Water Level

Look through the pump’s strainer lid. Is the basket empty or only partially filled with water?

A pump that lost its prime (little to no water in the pot) definitely ran dry. While you’re there, inspect for clogs. A basket packed with debris can starve the pump of water and cause dry running.

Remove any debris and ensure incoming lines are clear before restarting the pump.

3. Inspect Water Level and Valves

Verify the pool water level is at least at the midpoint of the skimmer. If water level was low, that explains the dry-run condition.

Also confirm all suction line valves were open. Check that nothing blocked the flow—like a skimmer weir stuck in the closed position. These simple oversights cause most dry running incidents.

4. Look for Leaks at the Seal Plate

With the pump off, use a flashlight to examine the joint between the motor and pump housing (seal plate area).

Any water dripping from this interface or wetness underneath the pump points to a failed shaft seal. If water is leaking even when the pump is off, the seal is definitely compromised.

Dry the area and observe carefully when the pump runs to ensure the water isn’t coming from a loose pipe fitting above.

5. Feel the Pump Housing Temperature

Carefully tap the pump housing and motor exterior. Does it still feel extremely hot long after shutdown?

Extreme residual heat indicates the pump overheated from dry running. Use an infrared thermometer to document the temperature if needed.

6. Listen on Restart (If Safe)

Once water supply is restored and the pump is reprimed, you might do a brief test run. Listen for grinding or screeching sounds.

Loud bearing noise could mean water penetrated the motor. Screeching could mean the new seal surfaces are damaged. Watch the pump’s pressure and flow—if it’s not pumping properly (low flow or pressure), the pump might still be air-bound or the impeller may be damaged.

If severe noises or lack of flow persist, shut it off again immediately.

7. Check the Timeline

How long did the pump run dry? The timeline tells you how serious the damage is.

30 seconds to 1 minute: Seal faces can crack or burn up. Water starts leaking at the bottom of the pump.

15 minutes to 1 hour: Los componentes plásticos, como la cesta de la bomba, pueden deformarse o ablandarse. Los devanados del motor comienzan a sobrecalentarse.

1-4 horas: Deformación del impulsor, daños más graves en el sello y degradación del aislamiento del motor.

6+ horas: Daño catastrófico: piezas plásticas fundidas, rodamientos agarrotados y posible quemado del motor.

Por qué sucede esto: Causas comunes

Nivel bajo de agua en la piscina

Esta es la causa principal del funcionamiento en seco. Cuando el nivel del agua de la piscina desciende por debajo del punto medio del skimmer, la bomba aspira aire junto con agua.

La evaporación, salpicaduras intensas o simplemente olvidarse de rellenar la piscina durante el clima caluroso pueden hacer que el nivel del agua baje rápidamente. Verifique el nivel del agua regularmente, especialmente durante el verano.

Skimmer o cestas de la bomba obstruidos

Hojas, cabello, insectos y residuos se acumulan en el skimmer y en las cestas de la bomba. Una cesta obstruida corta el suministro de agua a la bomba.

La bomba no puede aspirar suficiente agua, pierde la cebadura y funciona en seco. Esto sucede gradualmente, por lo que muchos propietarios de piscinas no se dan cuenta de que necesitan limpiar sus cestas hasta que ocurren daños.

Fugas de aire en las líneas de succión

Incluso si el nivel del agua de su piscina es correcto, las fugas de aire en el lado de succión de la tubería pueden romper la cebadura y causar funcionamiento en seco.

Los culpables comunes incluyen una junta tórica desgastada de la tapa de la bomba, tapones de drenaje flojos o accesorios de PVC agrietados. Si observa burbujas de aire en la cesta de la bomba, tiene una fuga de aire en algún lugar.

Válvulas cerradas o líneas bloqueadas

¿Alguien cerró accidentalmente una válvula? ¿Una línea está pellizcada o bloqueada?

Estos simples descuidos privan de agua a la bomba y la hacen funcionar en seco. Revise todas las válvulas de la línea de succión antes de asumir que su bomba tiene un problema.

Conclusión

La bomba de su piscina es el corazón de todo su sistema de circulación. Reconocer los signos tempranos de funcionamiento en seco (ruidos inusuales, olores a quemado, sobrecalentamiento y pérdida de flujo) le da la oportunidad de actuar antes de que ocurran daños catastróficos.

La diferencia entre un reemplazo rápido de sello por 300-400 dólares y un reemplazo de motor por 2,500 dólares a menudo se reduce a minutos. Si detecta un funcionamiento en seco temprano, apague la bomba inmediatamente, diagnostique qué lo causó y solucione el problema.