FFKM costs 329 times more than NBR. Is it worth it?

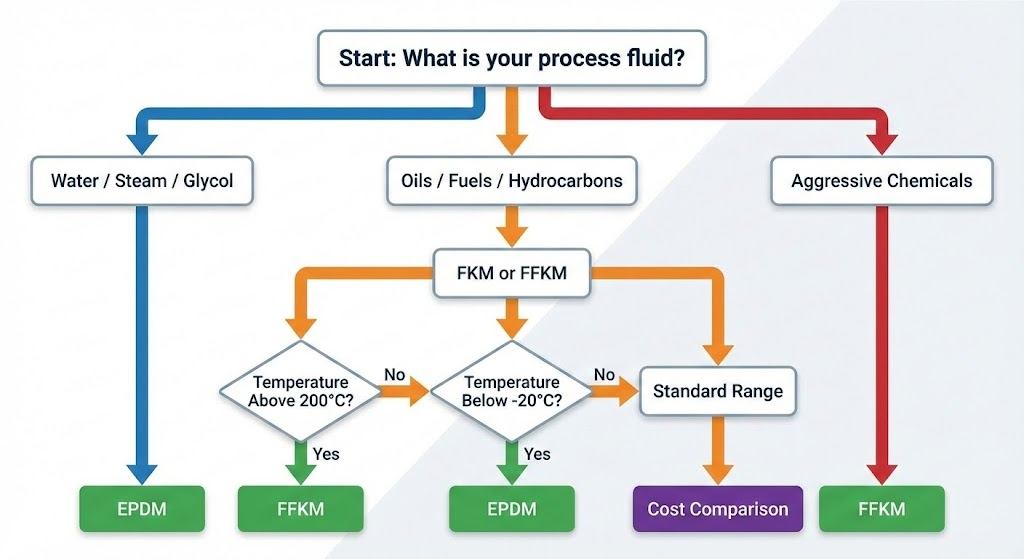

That depends entirely on your operating conditions. The answer is not always what you expect. EPDM outperforms FFKM in several critical applications, including water, steam, and low-temperature environments. Over-specifying FFKM for a water pump wastes money without improving seal life. Under-specifying EPDM for aggressive chemicals causes premature failure.

This guide provides a clear decision framework. Match the elastomer to your specific temperature, chemical, and cost requirements.

What Are FFKM and EPDM?

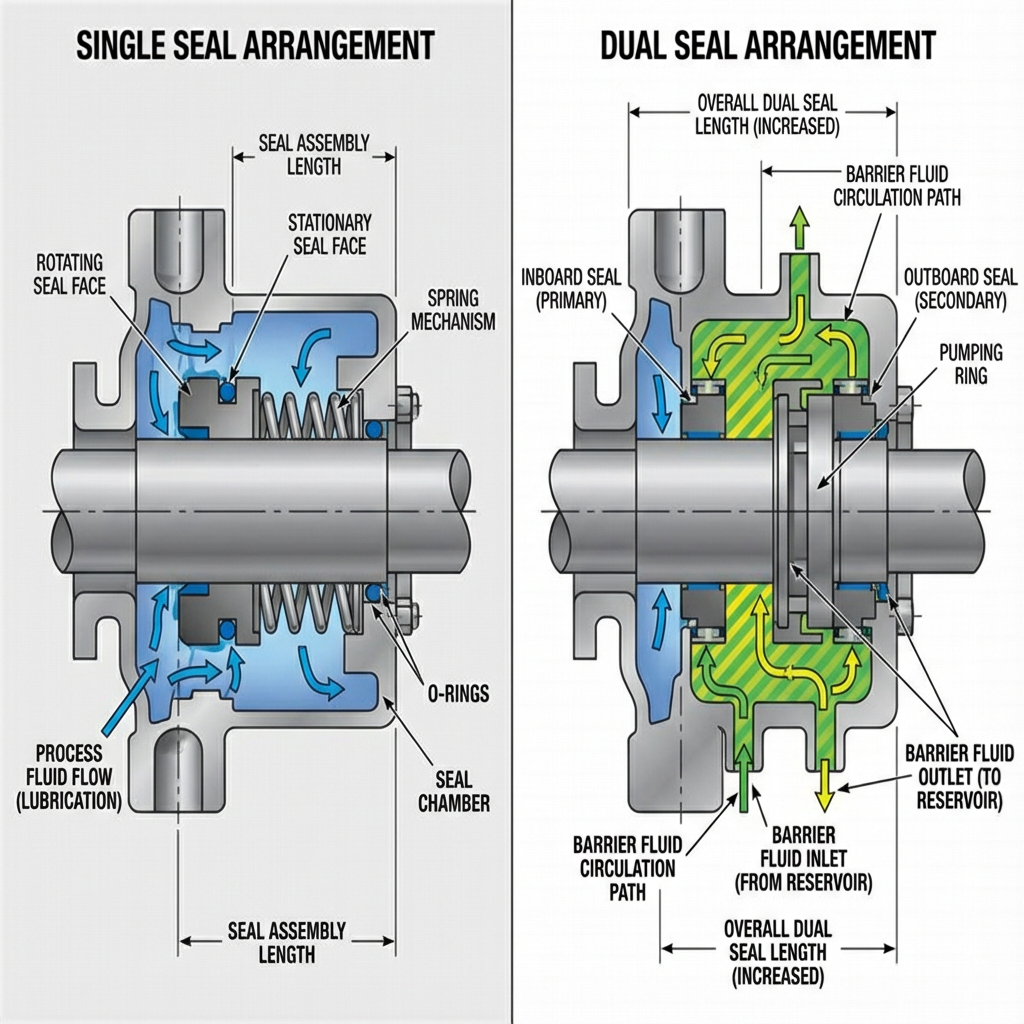

Both materials serve as secondary sealing elements in mechanical seals, but their chemistry determines vastly different performance envelopes.

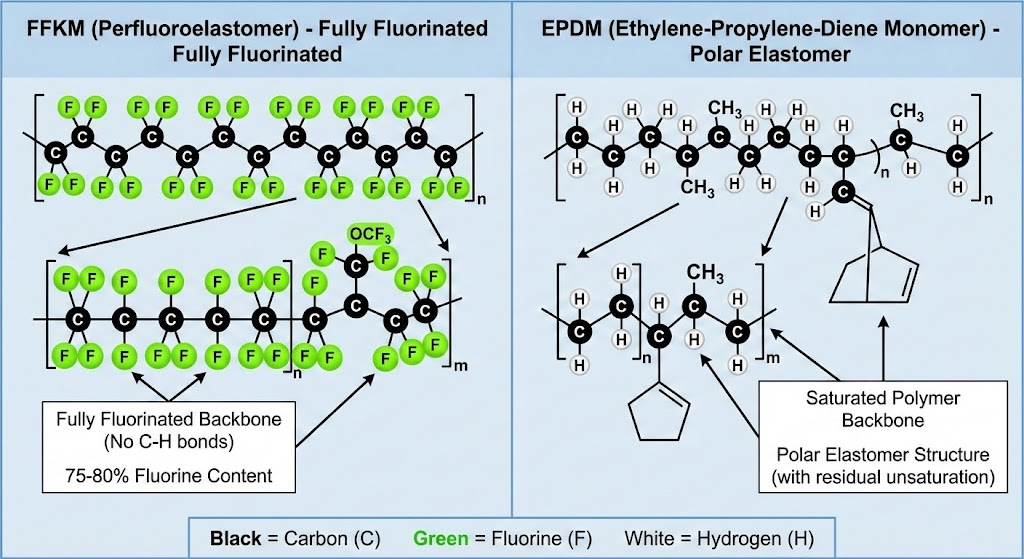

FFKM: The Fully Fluorinated Elastomer

FFKM (perfluoroelastomer) contains no carbon-hydrogen bonds. Its fully fluorinated backbone, with 75-80% fluorine content, eliminates most chemical attack vectors. This molecular structure gives FFKM near-universal chemical resistance.

Key specifications:

- Temperature range: -20C to +327C continuous

- Chemical resistance: 1,800+ chemicals, solvents, and plasmas

- Cost: 329x NBR (the most expensive elastomer available)

The fully fluorinated structure combines elastomeric flexibility with PTFE-like chemical resistance. However, this chemistry trades mechanical strength for chemical performance.

EPDM: The Versatile Workhorse

EPDM (Ethylene Propylene Diene Monomer) uses a saturated polymer backbone that provides exceptional resistance to ozone, UV, and weathering. As a polar elastomer, it excels with water-based fluids but fails with hydrocarbons.

Key specifications:

- Temperature range: -50C to +150C (specialty grades to 288C in steam)

- Tensile strength: 7-21 MPa (500-2500 psi)

- Elongation at break: 300-600%

- Cost: USD 5-10/kg raw material

EPDM offers superior mechanical properties at lower cost. For water and steam applications, I recommend EPDM over FFKM every time.

Which One Should You Choose?

Match the elastomer material to your operating conditions. Not price. Not reputation.

Choose EPDM When:

- Water, steam, or glycol-based fluids – EPDM excels here; FFKM offers no advantage

- Low-temperature applications below -20C – EPDM handles -50C; FFKM stops at -20C

- Outdoor exposure requiring UV/ozone resistance – Saturated backbone provides inherent stability

- Brake systems with glycol-based fluids – EPDM is the only appropriate choice

- Cost-sensitive applications without oil/fuel exposure

Choose FFKM When:

- Temperatures above 200C continuous – Standard EPDM fails above 150C

- Aggressive chemical environments – Acids, solvents, process chemicals

- Semiconductor or pharmaceutical applications – Ultra-clean, plasma-resistant

- Seal failure consequences are severe – Production loss, safety hazards, environmental incidents

- 1,800+ chemical compatibility required – No other elastomer matches this range

The decision is rarely about which material is “better.” It is about which material matches your specific conditions.

Temperature Comparison: Where Each Material Excels

Temperature capability drives most FFKM vs EPDM decisions. But the comparison is not one-sided.

High-Temperature Performance

| Material | Standard Limit | Maximum Capability |

|---|---|---|

| FFKM | 325C continuous | 327C (621F) specialty grades |

| EPDM | 150C standard | 288C specialty steam grades |

Per API 682, Type A mechanical seals with O-ring secondary seals are limited to 176C. This standard recognizes the practical limits of elastomeric sealing under pressure.

For high-temperature service, FFKM provides the widest operating margin. But specialty EPDM grades like E1121 can withstand steam up to 288C with excursions to 315C. Do not assume you need FFKM for steam applications.

Low-Temperature Performance

EPDM wins the low-temperature comparison decisively:

| Material | Glass Transition Temp | Practical Low Limit |

|---|---|---|

| EPDM | Below -50C | -50C |

| FFKM (standard) | -20C | -20C |

| FFKM (Chemraz 678) | -35C | -35C |

Standard FFKM becomes brittle below -20C. Specialty grades like Chemraz 678 extend this to -35C, but EPDM still outperforms at -50C. For cryogenic or cold-climate applications, EPDM is the correct material regardless of cost.

Pressure Effect on Temperature Ratings

Glass transition temperature shifts +1C per 50 bar increase in pressure. A seal rated for -20C at atmospheric pressure may only perform to 20C at 30,000 psi. Factor this shift into your selection for high-pressure pump applications.

Chemical Resistance: Key Differences

Chemical compatibility determines seal life more than any other factor in process applications.

FFKM Chemical Resistance

FFKM withstands attack from more than 1,800 chemicals, solvents, and plasmas. The fully fluorinated backbone eliminates the chemical attack vectors present in all other elastomers.

Excellent resistance to:

- Acids (most concentrations)

- Ketones and esters

- Aldehydes

- Ethers

- Amines (most grades)

- Fuels and oils

- Process solvents

Limitations exist: some FFKM grades remain vulnerable to amines, concentrated sulfuric acid, and concentrated nitric acid. Always verify compatibility for your specific grade and chemical concentration.

EPDM Chemical Resistance

EPDM performs exceptionally with polar fluids:

- Water and steam (excellent)

- Dilute acids and alkalis

- Ketones and alcohols

- Glycol-based coolants and brake fluids

- Ozone and UV exposure

EPDM fails with non-polar substances. This is not a weakness to overcome; it is a fundamental material property to respect.

The Oil Exposure Problem

EPDM is a polar elastomer. Exposure to non-polar substances like oils, fuels, and hydrocarbons causes swelling, softening, and seal failure.

Short-term exposure produces limited swell. Long-term exposure is catastrophic. The rubber continues absorbing hydrocarbon until complete structural failure.

Never use EPDM in oil, fuel, or hydrocarbon service. This is a hard limit, not a recommendation. If your application involves any oil exposure, select FKM or FFKM regardless of cost.

Cost Analysis: When Does FFKM Pay for Itself?

The price difference between EPDM and FFKM is extreme. Understanding total cost of ownership determines when the premium makes sense.

Raw Material Cost Comparison

| Material | Cost Ratio (vs NBR) | Relative Position |

|---|---|---|

| NBR | 1x (baseline) | Budget |

| EPDM | Low | USD 5-10/kg |

| FKM | 3.9x NBR (~8x EPDM) | Premium |

| FFKM | 329x NBR | Extreme premium |

The cost gap is real. FFKM should only be specified when no other elastomer can perform the function.

When FFKM Premium Is Justified

Calculate your true cost before specifying FFKM:

Total Cost = Acquisition + Installation + Downtime Cost

FFKM justifies its premium when:

- Downtime costs exceed seal costs by 10x or more

- Current materials fail within months, not years

- Seal failure creates safety or environmental incidents

- Production loss from a single failure exceeds the seal cost difference

A typical payback period runs about 9 months on critical applications. If your application does not meet these criteria, you are over-specifying.

Mechanical Properties Comparison

Material selection extends beyond chemical and thermal resistance. Mechanical properties affect seal function and longevity.

| Property | FFKM | EPDM |

|---|---|---|

| Hardness (Shore A) | 40-90 (typical 70-80) | 40-90 (typical 60-70) |

| Tensile Strength | Lower than EPDM | 7-21 MPa (500-2500 psi) |

| Elongation at Break | Varies by grade | 300-600% |

| Compression Set | Good | Good |

What This Means for Seal Performance

EPDM delivers superior mechanical properties at lower cost. Higher tensile strength and elongation provide better resilience under dynamic conditions.

FFKM trades mechanical performance for chemical and thermal resistance. This tradeoff makes sense only when chemical or thermal demands exceed EPDM capabilities.

For most water and steam applications, EPDM’s mechanical properties provide more than adequate performance. The lower hardness values typical of EPDM also improve sealing on imperfect surfaces.

Industry-Specific Recommendations

Application context determines material selection. These recommendations apply to common scenarios.

Pump Applications

| Application | Recommended Material | Rationale |

|---|---|---|

| Water pumps | EPDM | Cost-effective, excellent water resistance |

| Chemical pumps (water-based) | EPDM | Adequate resistance at lower cost |

| Chemical pumps (aggressive) | FFKM | Required for broad chemical compatibility |

| Hot oil pumps | FFKM or FKM | Never EPDM |

Understanding mechanical seal materials helps match components to pump service conditions.

Process Industries

Semiconductor manufacturing: FFKM required. Ultra-clean requirements and plasma exposure demand fully fluorinated elastomers.

Pharmaceutical processing: FFKM for aggressive CIP/SIP chemicals. FDA and USP Class VI compliance available. EPDM acceptable for water-based processes.

Steam systems: EPDM specialty grades. The assumption that fluorinated elastomers handle all high temperatures fails here. Select purpose-built steam grades like E1121.

General Guidelines by Media

| Process Media | Elastomer Selection |

|---|---|

| Water/steam | EPDM |

| Glycol coolants | EPDM |

| Dilute acids/alkalis | EPDM |

| Oils/fuels | FKM or FFKM (never EPDM) |

| Aggressive chemicals | FFKM |

| Solvents | FFKM |

For applications involving multiple media or uncertain conditions, consult detailed compatibility charts or contact an applications engineer to verify material suitability.

Conclusion

Material selection requires matching elastomer properties to operating conditions. EPDM excels in water, steam, and low-temperature applications at a fraction of FFKM cost. FFKM justifies its premium only when temperatures exceed 200C or aggressive chemicals are present.

Verify chemical compatibility for your specific process fluid before finalizing selection. Our engineering team can assist with material recommendations for challenging applications.