Most pumps have just one mechanical seal, though some specialized pumps use two (called a dual seal arrangement) for extra protection against leaks. The exact number depends on your pump’s design and what it’s pumping.

Here’s the simple truth: if you’re dealing with a standard water pump in your home or business, you’re looking at a single mechanical seal. But if you’re pumping hazardous chemicals or working with high-pressure systems, you might have two seals working together.

Single Seal Pumps

About 90% of pumps you’ll encounter use a single mechanical seal. These work perfectly for most applications – pumping water, oil, mild chemicals, or other non-dangerous fluids.

Single seals are cheaper and easier to maintain. When they eventually wear out (usually after 2-5 years of continuous use), you simply replace them during routine maintenance.

They’re ideal when:

- The pumped liquid isn’t toxic or extremely valuable

- Operating pressures are moderate

- A small amount of leakage won’t cause major problems

- Cost-effectiveness is important

Double (Dual) Seal Pumps

Some pumps use two mechanical seals arranged in tandem or back-to-back configurations. Think of it as wearing both a belt and suspenders – you’re doubling your protection against failure.

Between these two seals, there’s a barrier fluid that serves multiple purposes. It lubricates both seals, carries away heat, and acts as an early warning system if the primary seal starts to fail.

You’ll find dual seals in:

- Chemical processing plants handling toxic materials

- Pharmaceutical manufacturing where contamination must be avoided

- Oil refineries dealing with volatile compounds

- Food processing where product purity is critical

The extra seal adds significant cost – often doubling or tripling the price of the sealing system. But when you’re pumping sulfuric acid or liquid propane, that extra protection becomes invaluable.

Specialized Configurations

Some pumps break the one-or-two seal rule entirely. Multistage pumps might have a seal at each stage, meaning you could have three, four, or even more seals in a single pump assembly.

Magnetic drive pumps take a different approach altogether. They use zero mechanical seals by using magnets to transfer power through a sealed chamber. The trade-off? They’re more expensive and can’t handle as much power as traditional sealed pumps.

Submersible pumps often use a single mechanical seal combined with additional lip seals or packing for extra protection against water ingress. This hybrid approach gives them the reliability needed for underwater operation.

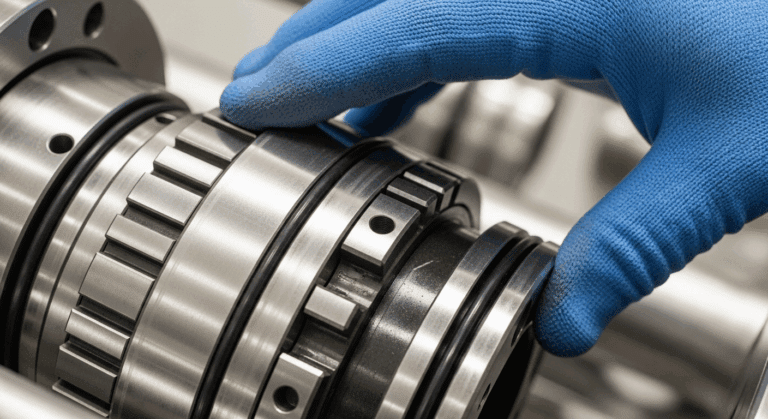

How to Tell How Many Seals Your Pump Has

Look at your pump’s nameplate or technical documentation – it should specify “single seal” or “dual seal” configuration. If that’s not available, check these visual cues:

- Seal chamber size: Dual seal chambers are noticeably larger to accommodate two seals

- External piping: Dual seals often have small tubes running to and from the seal area for barrier fluid circulation

- Flush plans: Look for API flush plan numbers – plans 52, 53, and 54 indicate dual seals

- Cost records: If the seal replacement cost seems unusually high, you probably have a dual seal system

Choosing the Right Number of Seals

Selecting between single and dual seals isn’t just about safety – it’s about finding the right balance for your specific needs.

Start by asking what you’re pumping. Water, oil, or other benign fluids almost always call for a single seal. Acids, bases, or flammable liquids often require dual seals for safety and environmental compliance.

Consider the consequences of a leak. If a seal failure means shutting down an entire production line or evacuating a building, the extra cost of a dual seal system pays for itself quickly.

Temperature and pressure matter too. Single seals handle most normal conditions fine, but extreme temperatures or pressures above 300 PSI often warrant dual seal protection.

FAQs

Can I convert a single seal pump to dual seal?

Converting requires significant modifications including a new seal chamber, different shaft, and auxiliary support systems. It’s usually more cost-effective to buy a pump designed for dual seals from the start.

How do I know if my pump needs a dual seal?

You need a dual seal if you’re pumping toxic, carcinogenic, or explosive fluids, if environmental regulations require zero emissions, or if seal failure would cause significant safety hazards or production losses.