Basic Parameters

- 0.05-0.08: PTFE, carbon graphite (ideal conditions)

- 0.10-0.15: Carbon vs stainless steel (typical)

- 0.15-0.25: Metal vs metal, poor lubrication

- 0.25-0.30: Harsh conditions, startup

Temperature Rise Calculation (Optional)

The fundamental equation Q = μ × P × V × A gives you heat generation in watts.

- The friction coefficient (μ) typically ranges from 0.05 to 0.3 for dry running seals. Lower values mean materials like PTFE or carbon graphite, while higher values indicate harder materials under poor conditions.

- Contact pressure (P) is measured in pascals or PSI. You’ll find this value from your seal manufacturer’s specifications or calculate it from the spring force divided by contact area.

- Sliding velocity (V) equals π × D × N / 60, where D is shaft diameter in meters and N is rotational speed in RPM. Higher speeds always mean more heat.

Step-by-Step Calculation Process

Start by gathering your seal’s operating parameters: shaft diameter, rotational speed, contact pressure, and material combination.

Calculate the sliding velocity first. For a 50mm shaft at 3,000 RPM, your velocity is 3.14 × 0.05 × 3000 / 60 = 7.85 m/s.

Determine your friction coefficient from material data tables. Carbon against stainless steel typically gives you 0.1 to 0.15.

Measure or calculate the seal contact area. For a face seal, this is π × (R²outer – R²inner) where R is the radius of the sealing surfaces.

Multiply all values together: Q = 0.12 × 100,000 Pa × 7.85 m/s × 0.0003 m² = 28.3 watts.

Converting Heat Generation to Temperature Rise

Heat generation alone doesn’t tell you if your seal will survive. You need to convert watts to actual temperature rise.

The temperature rise formula is ΔT = Q / (m × c × cooling factor), where m is seal mass, c is specific heat capacity, and the cooling factor accounts for heat dissipation.

Without cooling, a typical carbon seal generating 30 watts might experience a 50°C temperature rise. With proper cooling, this drops to 10-15°C.

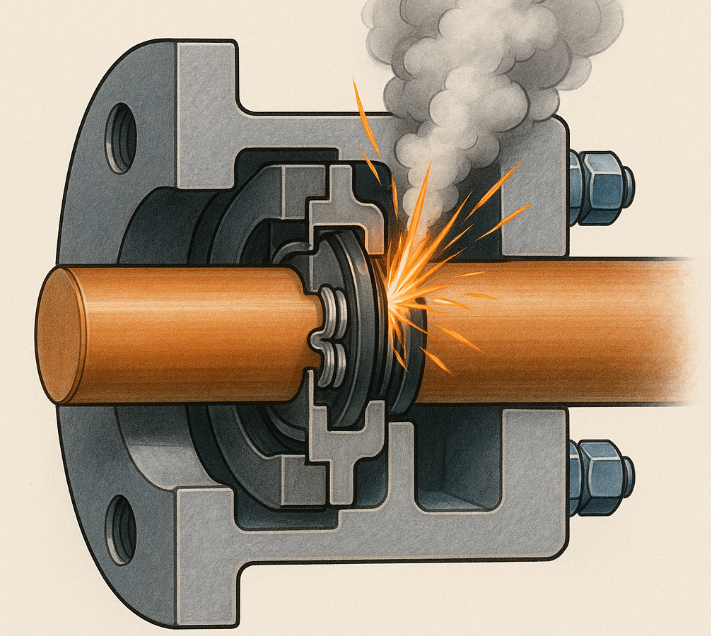

Common Mistakes to Avoid

- Never use wet seal friction values for dry running calculations. Dry friction coefficients are typically 5-10 times higher.

- Don’t forget to account for multiple sealing surfaces. Tandem seals generate heat at each interface.

- Always include a safety factor of 1.5 to 2. Real-world conditions rarely match ideal calculations.

- Temperature measurements must be taken at the sealing interface, not the housing. The actual seal face runs much hotter than surrounding components.

FAQs

What’s the typical heat generation range for dry running seals?

Most dry running seals generate between 10 and 100 watts of heat. Low-speed applications stay under 20 watts, while high-speed or high-pressure seals can exceed 75 watts without cooling.

How do I measure friction coefficient if it’s not provided?

Run the seal at known conditions and measure torque. Calculate backwards using τ = μ × F × r, where τ is torque, F is normal force, and r is radius.

Can I use the same formula for gas seals?

Yes, the basic formula applies to gas seals, but you’ll need different friction coefficients. Gas seals typically have μ values between 0.02 and 0.08.

Should I calculate heat for startup conditions?

Yes, startup generates the most heat due to higher friction before running-in. Use friction coefficients that are 50% higher for your startup calculations.