I’ve seen mechanical seals fail spectacularly from something simple: wrong flush pressure. One misadjusted regulator and suddenly you’re looking at catastrophic seal failure, process fluid leaking everywhere, and equipment down for days.

Flush plan pressure might seem like a minor detail, but it’s the difference between a seal lasting three years or three months. Get it right, and your seals run clean and quiet. Get it wrong, and you’ll be explaining a costly failure to your plant manager.

What is Flush Plan Pressure?

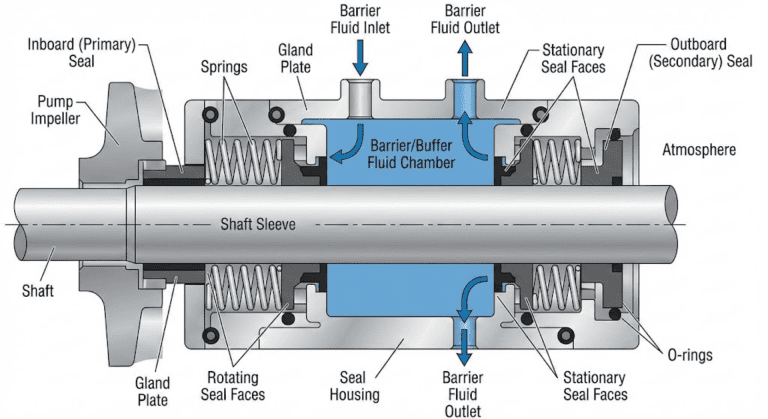

Flush plan pressure is the pressure at which clean external fluid is pushed into your seal chamber. Think of it as a protective barrier that says “process fluid, you don’t come past here.” This pressure must stay higher than the seal chamber pressure to work.

Your seal faces sit at the boundary between the clean flush fluid and your process fluid. If the flush pressure drops below the process pressure, even slightly, contaminated process fluid starts creeping back into the flush circuit. That’s when problems start—accelerated wear, face vaporization, and eventually seal failure.

When everything is set correctly, the flush fluid does three jobs: it blocks process fluid from entering, it cools the seal faces, and it lubricates them. That’s why the pressure band is so narrow—typically 10-15 psi above seal chamber pressure for Plan 32 systems. Too low and contamination wins. Too high and you crush the lubricating film between the faces.

Common Flush Plan Types and Their Pressure Ranges

Different API 682 flush plans have specific pressure requirements based on their design and application. The following table summarizes the most commonly used flush plans:

| Flush Plan | Description | Minimum Pressure | Typical Flush Pressure Above Chamber | Applications |

|---|---|---|---|---|

| Plan 32 | External flush from clean fluid source | 5 psi minimum above atmospheric | 10-15 psi above seal chamber | Standard applications with clean process fluids |

| Plan 53A | Barrier fluid reservoir (pressurized) | 20 psi above seal chamber | 20-30 psi above seal chamber | Hazardous or hot process fluids; dual seal configurations |

| Plan 53B | Barrier fluid with alternate pressurization | 20 psi above seal chamber | 20-30 psi above seal chamber | Applications requiring alternative pressure sources |

| Plan 54 | Seal water at higher pressure than process | 30 psi above seal chamber | 30+ psi above seal chamber | High-pressure pump applications; refinery duty |

Instrumentation Verification Checklist

Before you measure anything, verify your gauges are actually accurate. I’ve seen engineers make adjustments based on readings from an uncalibrated gauge—wasting hours troubleshooting a problem that never actually existed. Bad instrumentation gives bad data. Bad data leads to wrong adjustments.

Gauge Calibration Status:

Start here. Pull your gauge and check for a current calibration certificate (within 12 months). If it doesn’t have one, don’t trust it.

Gauge Accuracy Ranges:

Choose a gauge with roughly twice your expected operating pressure as its maximum. If you expect 12-15 psi, grab a 0-30 psi gauge, not a 0-100 psi. Here’s why: gauges are most accurate in the middle third of the dial. A 0-100 psi gauge showing 12 psi is barely visible and inaccurate. The same reading on a 0-30 psi gauge is right where it should be. Typical industrial gauges read ±1.6% of full scale—close enough when you’re in that sweet spot.

Instrument Installation Verification:

Walk the system and verify three things: (1) pressure taps are in the right locations per your P&ID (typically on the outlet side of flow control orifices), (2) block-and-bleed valves are installed at each tap, and (3) gauges are mounted properly. Snug the connections but don’t over-torque them—10-15 ft-lbs for typical NPT connections. If your equipment vibrates, fill your gauge with glycerin damping fluid to prevent the needle from bouncing around.

Safety Preparation

Working with pressurized systems can bite you if you’re not careful. I’m not exaggerating—pressurized flush systems can cause serious injuries. These safety steps are non-negotiable.

Lockout/Tagout Procedures:

Before touching anything, lockout the motor. Place your personal lock on the motor starter breaker, tag it with your name and the date, then try to start the motor from the control panel. It shouldn’t move. Now try to rotate the shaft manually to confirm it’s truly de-energized. Never, ever work on a pressurized system. Depressurize first, always.

Pressure Relief Valve Settings:

Check that all relief valves in your system are set and functioning. The setpoint should be no more than 10-20% above your normal operating pressure—this gives you a safety margin without letting pressure climb too high. If you need to test a relief valve, do it during planned maintenance windows, not while the plant is running.

System Depressurization Protocols:

Slow and steady wins here. Open the bleed valve gradually and give the system time to depressurize—typically 3-5 minutes for most flush systems. Don’t rush it. Rapid depressurization can cause temperature spikes that shock your components. Once pressure reads zero on the gauge, crack open the block valve just slightly. If fluid drips out, keep bleeding. Once you confirm zero pressure, it’s safe to disconnect gauges.

Measuring Flush Plan Pressure: Practical Procedures

Follow these five steps to accurately measure, monitor, and adjust your mechanical seal flush plan pressure.

Step 1: Inspect and Prepare Measurement Points

Walk up to your system and find the pressure measurement taps. This is where you’ll connect your gauge.

Locating Pressure Taps:

For Plan 32 systems, look on the discharge side of your pump and on the seal chamber return line. For Plan 53A systems, the taps are on the circulator unit return line. Pull out your mechanical seal layout drawing or P&ID—they show exactly where these taps are located. Mark the correct taps with temporary labels so you don’t measure the wrong line. I’ve seen technicians spend 20 minutes measuring suction pressure instead of flush pressure because nobody marked the lines.

Cleaning Connection Points:

The tap connection probably has dust and corrosion on it. Wipe it clean with a cloth, then use a wire brush to gently remove any oxidation from the threads. If the tap is heavily corroded or damaged, don’t use it—contact your equipment vendor for an alternative. For taps that haven’t been used in months, slowly crack the block valve to let any sediment or trapped air escape before you install your gauge.

Confirming Block Valve Installation:

Every pressure tap must have a block valve right at the connection point. It’s your safety valve—allows you to isolate and bleed pressure safely. Check that the block valve is closed before you start. Turn the handle through a full cycle to confirm it moves freely. If there’s no block valve installed, stop. Have one installed before you proceed. A proper setup has three components: the block valve (to isolate), the gauge port (where your gauge connects), and the bleed valve (to release pressure).

Step 2: Select and Install Appropriate Gauges

Grab a gauge with roughly twice your expected operating pressure as the maximum range.

Pressure Gauge Range Selection:

Check your equipment specs for your expected flush pressure (typically 10-15 psi for Plan 32, 20-30 psi for Plan 53A). A gauge that’s too large gives you a needle sitting barely visible on the left side of the dial. Not useful. A 0-30 psi gauge reading 12 psi is clear and accurate. A 0-100 psi gauge reading the same pressure is guessing.

Material Compatibility:

Before installing, verify your gauge material matches your flush fluid. Water-based systems use standard stainless steel. Oil-based barrier fluids need gauges that won’t corrode from chemical exposure. If you’re unsure about your fluid chemistry, check the manufacturer’s compatibility chart or install a diaphragm seal to separate the gauge from direct fluid contact.

Connection Torque Specifications:

Hand-tighten first to make sure threads line up. Then use a wrench to tighten to the manufacturer’s spec (typically 10-15 ft-lbs for standard NPT connections). Not finger-tight, not hand-over-hand, but a firm wrench-turn. Once the gauge is reading pressure, check for leaks around the connection. If it’s weeping, increase torque slightly in small increments until it stops.

Step 3: Monitor at Startup

Watch the gauge like a hawk when you start the pump. Don’t just walk away.

Initial Pressure Readings During System Start:

Hit the start button. Within 10-15 seconds, you should see pressure rising on the gauge. Record readings at 30 seconds, 1 minute, and 2 minutes. Watch for anything weird: sudden spikes, erratic bouncing, or pressure that never climbs. These are red flags telling you something’s wrong.

Pressure Stabilization Observation:

Keep watching for 5-10 minutes until everything settles out. Healthy pressure climbs gradually and plateaus around 10-15 psi above your seal chamber pressure. If pressure keeps climbing past expected values, the regulator is probably misset or stuck. If it’s stuck low, you’ve got a leak, a blocked filter, or an undersized flow line. A normal startup looks like a smooth ramp that levels off in about 5 minutes.

Step 4: Record Operating Pressure

Baseline Documentation:

Create a simple log sheet with: pump ID, date, time, ambient temperature, actual flush pressure reading, and anything unusual you observed. For the first month, record weekly. Then switch to monthly. Include RPM, flow rate, inlet/outlet pressures, and fluid temperatures.

Comparing Actual vs. Design Pressure Values:

Pull your equipment specs. They show the design pressure your seal was engineered for. Compare your measured value against that specification. You should be within ±3 psi. If you’re outside that band, something’s changed—either the process got hotter, the regulator drifted, or there’s a system modification. When discrepancies show up, dig into the cause before you adjust anything.

Step 5: Adjust Pressure if Needed

Don’t just leave it if the pressure is wrong. Fix it. But do it carefully.

Opening/Closing Flow Control Orifices:

Plan 32 systems use a simple orifice (restrictor) to control flow and pressure. Smaller orifice = higher pressure. Larger orifice = lower pressure. The trade-off is you have to shut down the system, swap the orifice, and restart. Orifice sizes typically range from 0.040″ to 0.125″ diameter. Check your seal vendor’s sizing chart for the specific orifice that gives you your target pressure. After you swap it, run the system and verify the new pressure. Document the change.

Regulator Adjustments:

Plan 53A systems have adjustable regulators—much easier. Find the adjustment screw (usually under a cap on top of the regulator). Clockwise increases pressure, counterclockwise decreases it. Small turns work best: typically 1-2 psi per quarter turn. After each adjustment, wait 2-3 minutes for the system to settle, then remeasure. Don’t crank on it all at once.

Iterative Fine-Tuning:

Adjust in 5 psi increments. Measure. Wait 2-3 minutes. Measure again. Repeat until you hit your target. Example: Measuring 8 psi, need 12 psi. Adjust to ~10 psi. Wait and remeasure. Now adjust to ~12 psi. Wait and verify it’s stable. Once you get to target, lock the adjustment screw to keep it from drifting.

FAQs

How often should I check mechanical seal pressure?

Check at startup, then monthly for the first three months. After that, quarterly is fine for stable systems. But here’s the thing: if you start seeing pressure drift over time, switch to weekly checks until you figure out why. For critical pumps or hot-fluid applications, spend the money on continuous electronic monitors. They catch problems while you’re asleep.

When should I adjust the flush pressure?

Only when you’re outside your design band (typically ±3 psi). Don’t fiddle with it constantly—that causes hunting and instability. Adjust when: pressure consistently runs low, you’ve changed the process (and seal chamber pressure increased), or you just swapped a seal. Always document why you made the change.

How do I know if pressure is too high or too low?

Low pressure signs: leakage increasing, leakage color changing (meaning process fluid is mixing in), temperatures creeping up. The seal gets hungry for the process fluid to cross the barrier. High pressure signs: sudden leakage spike, high temperatures, squealing or noise from the seal, fast wear. You’re crushing the lubricating film. Stay within your ±3 psi band and you’re fine.

What’s the relationship between temperature and pressure?

Pressure and temperature are locked together. Every 10°F temperature rise causes roughly 1-2 psi pressure increase in a sealed system. But there’s more: hotter fluid means higher vapor pressure. At some point, your fluid just wants to boil. That’s why API 682 demands that 50 psi minimum vapor pressure margin. When your process gets hotter, you have to raise flush pressure to keep that margin. Always log both pressure and temperature. Sometimes what looks like a pressure problem is just the plant running hotter than normal.