A mechanical seal fails unexpectedly, and your pump starts leaking. You rush to replace it, but within weeks, the new seal fails too. The problem isn’t the seal—it’s the shaft. Excessive shaft runout is one of the leading causes of premature seal failure in industrial pumps, and most technicians never measure it before installation.

Essential Tools and Equipment

- Dial Indicators

- Magnetic Base and Indicator Holders

- Shaft Coupling or Reference Surface

- Optional: Laser Alignment Equipment

Step-by-Step Measurement Procedure

Step 1: Prepare the Measurement Workspace

Clear the area around the pump shaft and remove any obstacles that might interfere with rotating the shaft by hand. Ensure the pump is de-energized and locked out per your facility’s safety procedures. Verify the shaft can rotate freely without hitting anything. Wipe the shaft and coupling surfaces clean with a lint-free cloth to ensure the indicator makes good contact.

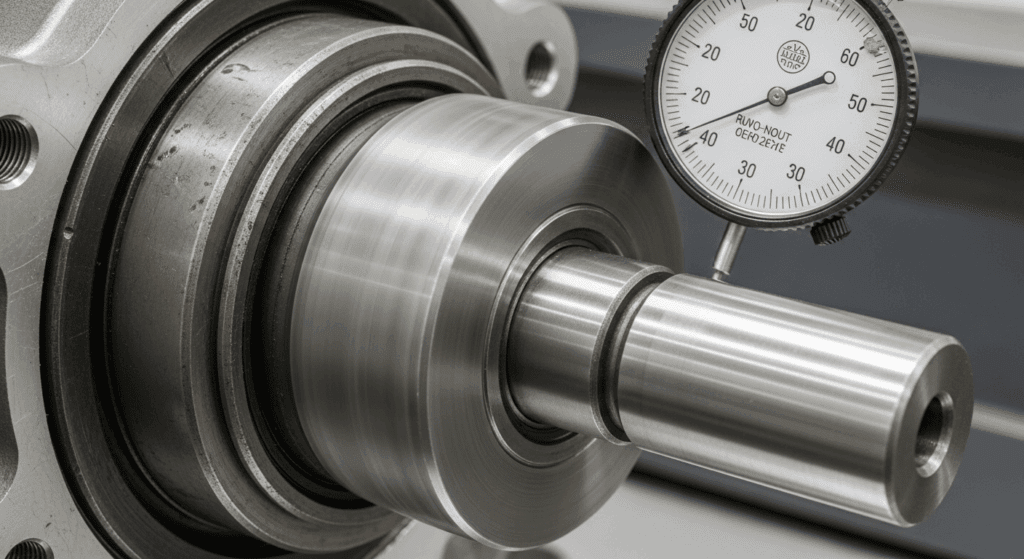

Step 2: Mount and Zero the Dial Indicator

Attach the magnetic base to a fixed metal surface positioned perpendicular to the shaft. Place the dial indicator tip lightly against the shaft or coupling surface. The indicator tip should contact the surface at roughly the middle of its travel range (not at either extreme).

Rotate the indicator face until the zero mark aligns with the needle. This is your zero or baseline measurement.

Step 3: Rotate Shaft and Record Measurements

Slowly rotate the shaft by hand through a complete 360-degree rotation. Watch the needle as it moves—it will show high points and low points on the shaft surface. Rotate the shaft at least 2-3 complete rotations to confirm your readings are consistent.

Note the maximum value the needle reaches (the highest reading as the shaft rotates) and the minimum value (the lowest reading). If the needle goes below zero, record that as a negative number.

Step 4: Interpret TIR (Total Indicated Runout)

TIR stands for Total Indicated Runout. It’s the difference between the maximum and minimum readings you recorded. Subtract the minimum value from the maximum value to get your TIR.

For example, if your highest reading is 0.004 inches and your lowest is -0.001 inches, your TIR is 0.005 inches (0.004 minus negative 0.001 equals 0.005). This TIR value tells you how much the shaft wobbles or moves off-center as it rotates.

Compare your TIR to the acceptable tolerance for your pump. Most mechanical seals require runout below 0.005 inches (0.13 mm) TIR. For high-speed pumps running faster than 3,600 RPM, the tolerance should be tighter—no more than 0.001 to 0.002 inches (0.025 to 0.05 mm) TIR. Check your seal manufacturer’s specifications for the exact requirement.

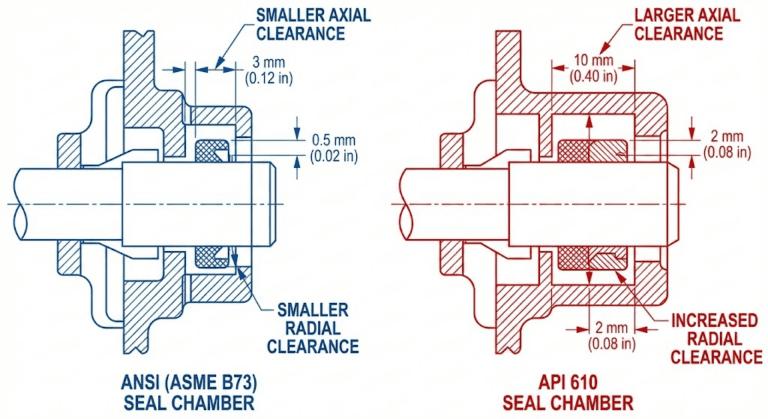

Step 5: Verify Seal Chamber Register

After measuring shaft runout, reposition your indicator to measure the seal chamber register (the mounting surface where the stationary seal component sits). Mount the indicator perpendicular to this surface and repeat the rotation and measurement process.

The seal chamber register should also show minimal runout—typically no more than 0.002 inches TIR. If the seal chamber runout exceeds this, you may need to machine or replace the seal housing.

Record both the shaft runout and seal chamber runout measurements. Both must be within tolerance for the seal to function properly.

Step 6: Document and Compare to Standards

Write down all your measurements on your installation checklist or work order. Include the date, pump model, shaft diameter, maximum reading, minimum reading, calculated TIR, and acceptable tolerance range.

Compare your measured TIR to the manufacturer’s specification. If your measurement is below the maximum allowable runout, you’re cleared to proceed with seal installation. If your measurement exceeds the maximum, stop and troubleshoot before installing the seal.

FAQ: Common Questions About Shaft Runout Measurement

Can I measure shaft runout with the pump running?

No, always measure with the pump stopped and de-energized. Measuring a running shaft is dangerous and gives false readings because the shaft moves under load differently than it does at rest. Measure before installation and after the pump is commissioned to monitor for changes over time.

How often should I check shaft runout?

Measure shaft runout before every seal installation. After installation, monitor the pump’s vibration and temperature during the first 24 hours of operation. If vibration is normal, the seal is likely functioning properly. Repeat full runout measurements annually or whenever you service the pump.

What if my shaft runout is slightly over tolerance—can I still install the seal?

No, don’t proceed if runout exceeds the manufacturer’s specification. Excessive runout causes the seal faces to separate, resulting in immediate leakage. Install a new seal correctly or correct the runout problem first. Trying to save time will cost you far more in emergency downtime and seal replacement costs.