An API mechanical seal and a non-API mechanical seal differ in their design and performance standards.

API seals adhere to strict guidelines set by the American Petroleum Institute, ensuring reliability in demanding industrial applications.

In this post, we’ll explore these differences and help you choose the right seal for your needs.

What is API 682 Standard

API 682 is a standard developed by the American Petroleum Institute (API) that provides guidelines for the design, selection, and operation of mechanical seals in centrifugal and rotary pumps used in the petroleum, natural gas, and chemical industries. This standard aims to improve the reliability and performance of mechanical seals in these critical applications.

The API 682 standard covers various aspects of mechanical seals, including:

- Seal types and configurations

- Materials of construction

- Seal design requirements

- Testing and qualification procedures

- Installation, operation, and maintenance practices

Differences Between API Mechanical Seals and Non-API Mechanical Seals

Standards and Specifications:

API mechanical seals: Designed and manufactured according to the API 682 standard, which provides comprehensive specifications for the design, materials, testing, and operation specifically for the petroleum, natural gas, and chemical industries. It defines different seal categories, types, arrangements, and piping plans to cover a wide range of applications and operating conditions.

Non-API mechanical seals: Do not necessarily follow the rigorous standards of API 682. These seals have more flexibility in their design and configuration, allowing for variations that might not meet the stringent requirements set for API seals.

Materials and Construction:

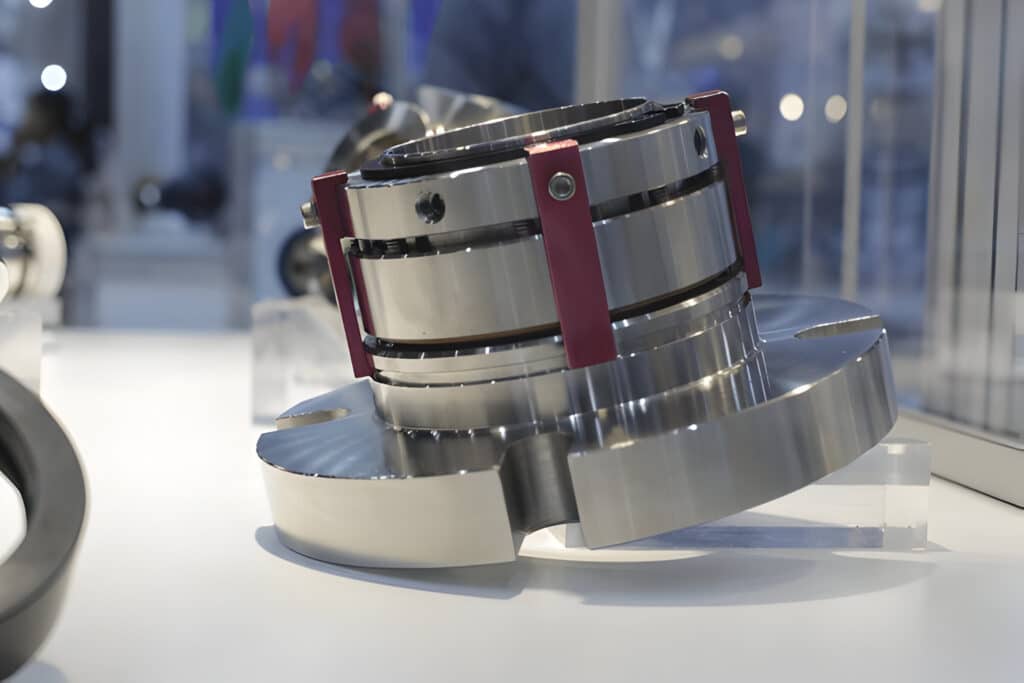

API mechanical seals: Utilize high-quality, durable materials capable of withstanding demanding conditions like high pressures, temperatures, and aggressive fluids. Common materials include premium, hard face materials such as silicon carbide, tungsten carbide, or graphite loaded silicon carbide. They feature robust construction with elements like metal bellows, balanced seal faces, and dual seals to enhance reliability.

Non-API mechanical seals: May use a broader variety of face materials and elastomers, influenced by application specifics and cost considerations. The construction might not always employ the most robust, expensive materials, and can have simpler designs.

Testing and Quality Control:

API mechanical seals: Subject to stringent qualification testing as required by API 682 to ensure reliable, long-term operation for at least 25,000 hours.

Non-API mechanical seals: Might not undergo the same level of rigorous performance testing. Their quality control and documentation requirements are typically less comprehensive, focusing on standard rather than extreme conditions.

Application and Industry:

API mechanical seals: Primarily used in demanding environments such as oil and gas, refineries, and petrochemical applications that require high levels of safety, reliability, and emissions control.

Non-API mechanical seals: More commonly employed in general industrial, chemical, water, and other less critical applications where the operating conditions involve lower pressures and temperatures. Generally less expensive, these seals are suited for a wider range of less demanding applications.

Conclusion

In conclusion, understanding the differences between API and non-API mechanical seals is crucial for selecting right seal for your application.

API seals offer superior performance and reliability in demanding industrial environments, while non-API seals are suitable for less critical applications.

For expert guidance on choosing the best mechanical seal for your needs, contact our team today.