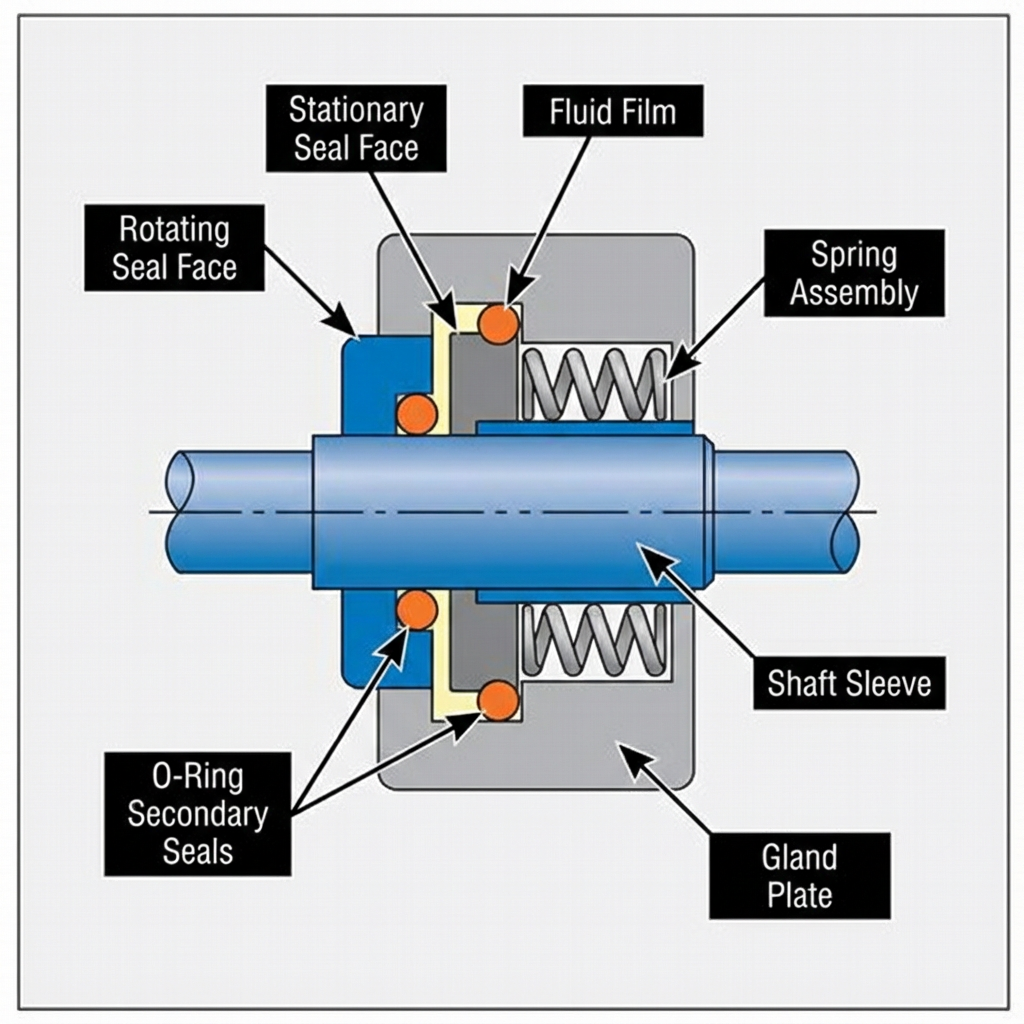

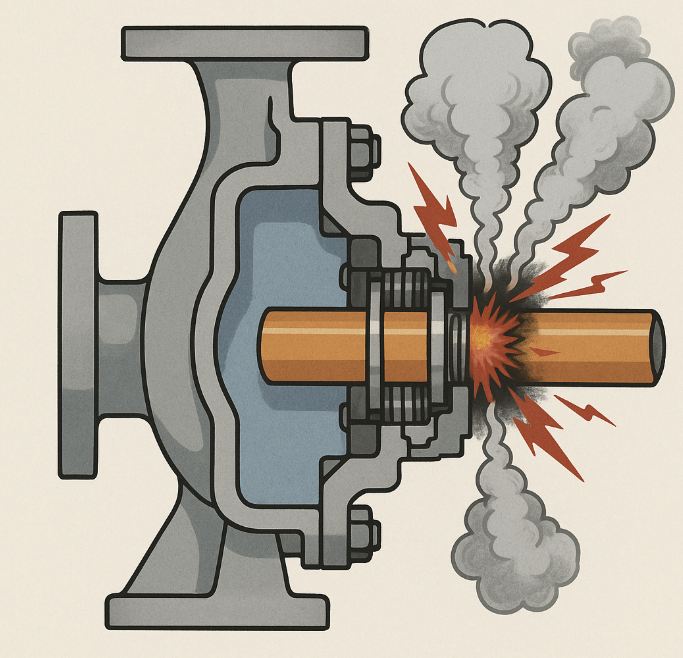

Dry running destroys mechanical seals in minutes, causing catastrophic pump failure and thousands of dollars in damage. It happens when your seal operates without proper lubrication—essentially running metal against metal at high speeds with no cooling or lubricating fluid between the seal faces.

The good news? You can prevent dry running completely with the right approach. This guide shows you exactly how to protect your mechanical seals and keep your pumps running reliably.

Modify Your Operating Procedures

- Verify liquid level before startup: Always check the liquid level in the suction source before starting any pump. A simple sight glass or level indicator prevents most dry running incidents.

- Prime the pump completely: Open vent valves to release trapped air before startup, and never start the pump until you see steady liquid flow from the vents.

- Install a minimum flow bypass line: For variable flow applications, implement a bypass line to ensure continuous circulation through the seal chamber even when the main discharge is restricted.

Install a Flush Plan

- API Plan 11: Sends pumped fluid from the discharge back to the seal chamber, maintaining circulation even during low-flow conditions and ensuring constant liquid flow to your seal faces

- API Plan 23: For high-temperature applications, uses a cooling loop to keep the seal faces below the fluid’s vaporization temperature

- API Plan 53 or 54: Double seals that provide the ultimate protection by using a separate barrier fluid system that maintains lubrication regardless of process conditions

Add Monitoring Systems

- Flow meters on flush lines: Give you immediate warning when seal lubrication stops. Set them to trigger an alarm or automatic pump shutdown when flow drops below safe levels.

- Temperature sensors at the seal chamber: Detect the rapid heat buildup that signals dry running. A temperature spike of just 20°F above normal often indicates trouble.

- Vibration monitors: Catch the unusual patterns created by dry running seals. The grinding of dry faces creates distinct frequency signatures your monitoring system can recognize.

FAQs

How quickly does dry running damage a mechanical seal?

Severe damage occurs within 30-60 seconds of dry running. The seal faces can reach destructive temperatures in less than 10 seconds, with complete failure typically happening within one minute.

Can a mechanical seal recover from brief dry running?

Brief dry running under 5 seconds might not cause visible damage, but it still creates micro-cracks that shorten seal life. Any dry running over 10 seconds usually requires seal replacement.

Which seal materials handle dry running best?

Silicon carbide against silicon carbide offers the best dry running resistance. These hard faces can survive brief dry contact that would destroy carbon faces instantly.

Should I use dry-running seals instead of prevention methods?

Dry-running seals only tolerate brief periods without lubrication and cost significantly more. They’re a backup measure, not a replacement for proper seal support systems.

How do I know if my current flush plan is adequate?

Measure the temperature rise across your seal chamber. If it’s over 15°F during normal operation, your flush plan isn’t providing enough cooling and lubrication flow.