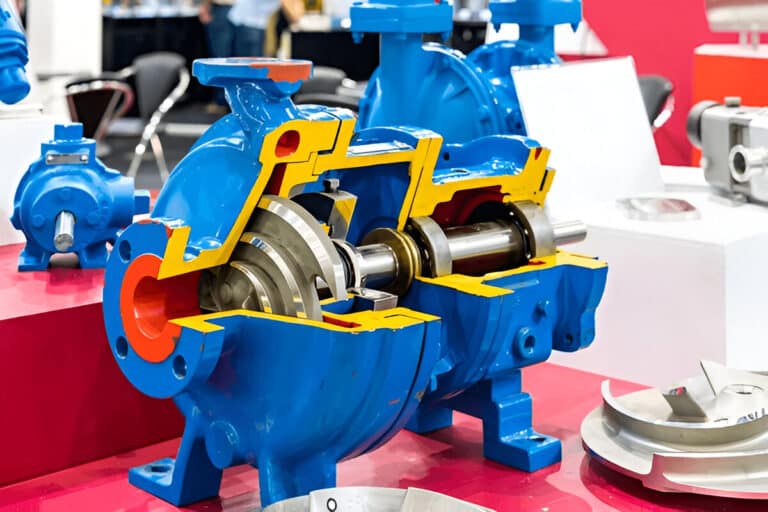

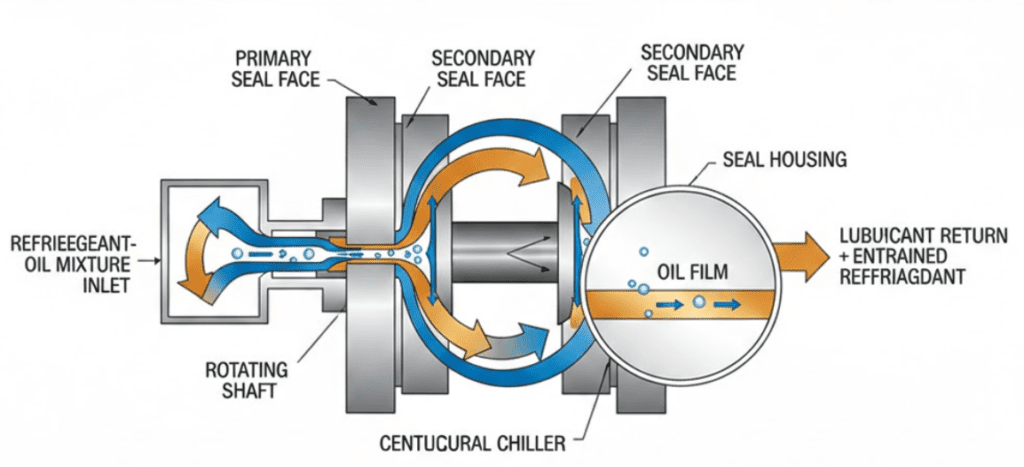

Open-drive centrifugal chillers lose an average of 2% of their refrigerant charge annually through shaft seals. The refrigerant doesn’t escape as gas—it leaks out entrained in the lubricant oil. This pattern tells you something critical about seal material selection: the oil matters more than the refrigerant gas.

Most compatibility guides focus on refrigerant-to-elastomer matching. They’ll tell you which rubber works with R-410A or R-134a. But your seal doesn’t encounter pure refrigerant. It encounters a refrigerant-oil mixture, and that mixture behaves very differently.

Why Oil Compatibility Matters More Than Gas Compatibility

The AHRI Material Compatibility and Lubricant Research program at Purdue University tested elastomers in three conditions: 100% refrigerant, 50% refrigerant with 50% lubricant, and 100% lubricant. Different system locations expose seals to different mixture ratios. Liquid-rich zones near the compressor see high oil concentrations, while vapor lines see mostly refrigerant gas.

The results showed distinct behavior across these conditions. Butyl rubber, for example, blistered only in the 50:50 mixture exposures—not in pure refrigerant. This finding changes how you should approach material selection.

Consider the POE oil problem. Polyol ester oils used with HFC and HFO refrigerants undergo hydrolysis when exposed to moisture. Water breaks POE into acids and alcohols. This process is irreversible. Those acids attack elastomer seals in ways the refrigerant itself never would.

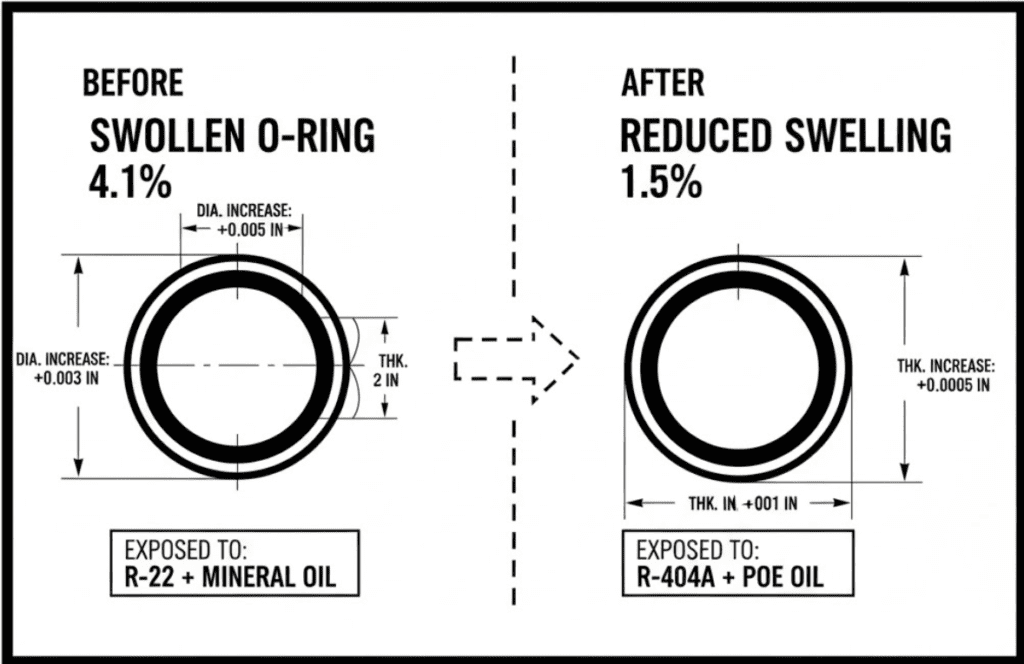

I’ve seen this pattern repeatedly during refrigerant conversions. A Neoprene O-ring that swelled 4.1% with R-22 and mineral oil showed only 1.5% swelling when exposed to R-404A and POE oil. The 2.6% difference caused seals that had been tight for years to suddenly leak. The refrigerant changed, but the oil change caused the real problem.

My recommendation: When evaluating seal compatibility, check the lubricant oil first. POE and PVE oils have completely different compatibility profiles. A seal that works perfectly with one may fail with the other, regardless of which refrigerant you’re using.

Elastomer Selection by Refrigerant Type

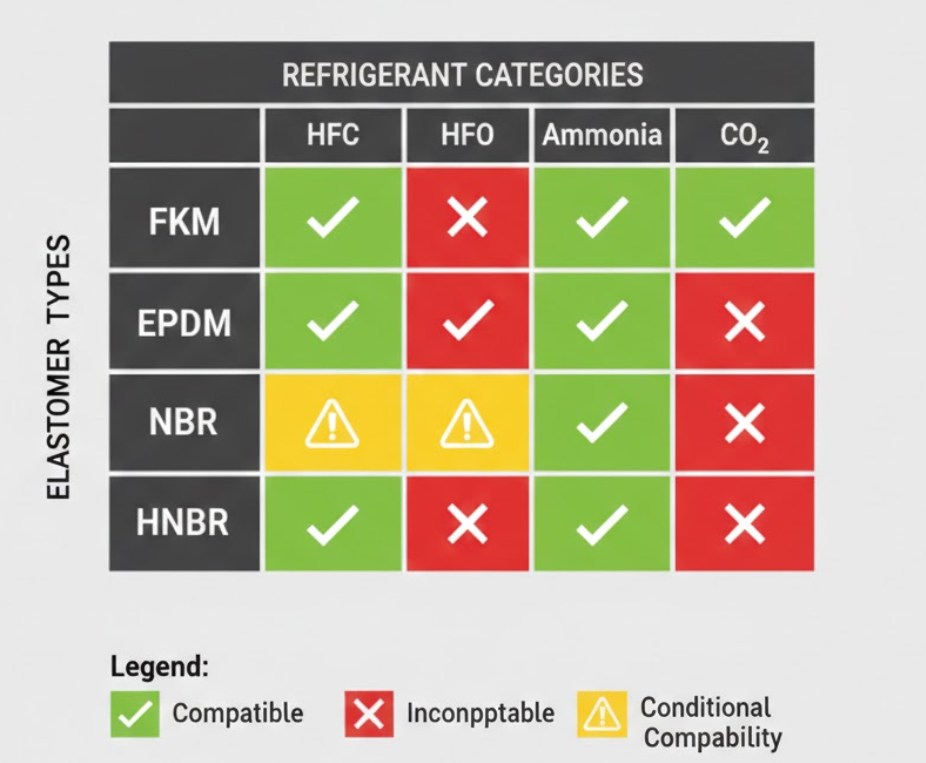

The four common elastomer types in mechanical seals each have distinct refrigerant compatibility profiles. Here’s what actually works in the field.

HFC Refrigerants (R-410A, R-134a)

FKM (Viton) handles most HFC refrigerants well. Operating range spans -30C to 205C, covering virtually all HVAC chiller applications. EPDM also works but offers less chemical resistance to the oils typically paired with these refrigerants.

NBR (Buna-N) shows marginal compatibility with HFCs. The fluorine content in these refrigerants can extract plasticizers from NBR compounds over time. For critical applications, upgrade to FKM.

HFO Refrigerants (R-1234yf, R-1234ze)

The low-GWP HFO refrigerants present newer compatibility challenges. R-1234ze has a GWP less than 1—99.9% lower than R-134a—making it increasingly common in new installations.

Early research suggests FKM maintains good compatibility with most HFO compounds. However, testing protocols are still evolving. I recommend requesting specific compatibility data from your seal supplier for any HFO application rather than assuming HFC compatibility translates directly.

Natural Refrigerants (Ammonia, CO2)

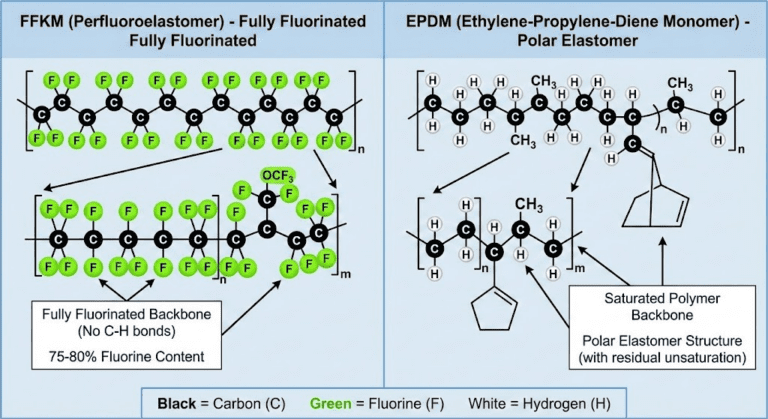

Here’s where conventional wisdom fails. FKM—the default “premium” choice for most refrigerant applications—is rated unsuitable for ammonia service. Chemical compatibility charts rate FKM at 4 (not recommended) for both cold and hot ammonia gas.

EPDM rates 1 (excellent) for ammonia. The cost difference is significant—EPDM typically runs 30-50% less than FKM—and the performance is actually better in this application.

For CO2 systems, EPDM again outperforms FKM in most configurations. The exception is high-pressure transcritical CO2 systems, where HNBR or FFKM may be necessary to handle the extreme pressures and permeation rates.

| Refrigerant Type | Recommended Elastomer | Avoid |

|---|---|---|

| R-410A, R-134a | FKM, EPDM | NBR for critical service |

| R-1234yf, R-1234ze | FKM (verify with supplier) | Silicone |

| Ammonia | EPDM | FKM |

| CO2 (subcritical) | EPDM | FKM |

| CO2 (transcritical) | HNBR, FFKM | Standard FKM |

How Elastomers Fail in Refrigerant Service

Seal failure from refrigerant incompatibility follows two distinct mechanisms.

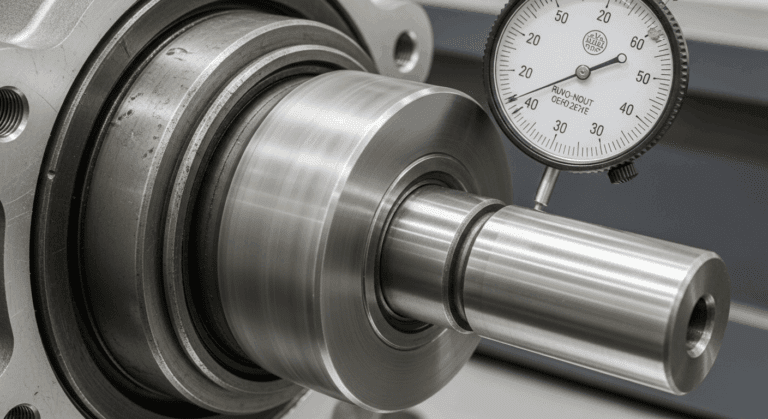

Swelling occurs when the elastomer absorbs refrigerant or oil. The seal expands, often unevenly. Moderate swelling (under 10%) may actually improve sealing initially—the seal fits tighter in its groove. But excessive swelling causes extrusion past retaining hardware, stress cracking, and eventual rupture.

Extraction is the opposite problem. Refrigerant-oil mixtures leach plasticizers and other compounds out of the elastomer. The seal shrinks, hardens, and loses flexibility. This explains why seals that performed well for years suddenly fail after refrigerant conversions—they’re experiencing reverse swelling as the new refrigerant extracts different compounds than the old one deposited.

Both mechanisms can occur simultaneously in different zones of the same seal, depending on local temperature and mixture concentration.

When seals fail prematurely in chiller pump applications, the wear patterns reveal the cause. Uniform hardening across the seal surface suggests extraction. Localized bulging or extrusion points to swelling. Either pattern, if present on a relatively new seal, indicates a material compatibility problem rather than normal wear.

Practical Selection Framework

Start with oil compatibility, not refrigerant compatibility. Identify whether your system uses POE, PVE, or mineral oil. This narrows your elastomer options more than the refrigerant choice does.

Step 1: Identify the lubricant oil type. POE oils require attention to moisture control and acid formation. PVE oils offer better moisture tolerance but different elastomer interactions. Mineral oils (increasingly rare in modern systems) have well-established compatibility data.

Step 2: Match elastomer to oil chemistry. Request compatibility data specific to your oil brand if possible. Generic “POE compatible” ratings may not account for additive package variations between manufacturers.

Step 3: Verify refrigerant compatibility as secondary check. Most elastomers compatible with the oil will also handle the refrigerant. The exceptions—like FKM with ammonia—are well documented.

Step 4: Account for temperature extremes. Standard FKM works to 205C; EPDM to 150C. If your application sees temperature excursions, select materials with margin.

For any refrigerant conversion, replace all elastomer seals regardless of their apparent condition. Seals that took a set with one refrigerant-oil combination will experience differential swelling with the new combination. The six-month lag before leaks appear often masks the true cause—by then, you’ve forgotten the conversion.

Making the Right Choice

The refrigerant flowing through your chiller matters less to seal selection than the oil carrying it. Focus material selection on the lubricant compatibility first, refrigerant compatibility second.

For systems using POE oils with HFC or HFO refrigerants, FKM remains the workhorse elastomer. For ammonia or CO2 natural refrigerant systems, specify EPDM—it outperforms the more expensive FKM in these specific applications.

When in doubt, request actual test data rather than relying on generic compatibility charts. The 50:50 mixture behavior your seals will actually encounter may differ from the pure-refrigerant ratings most charts provide.