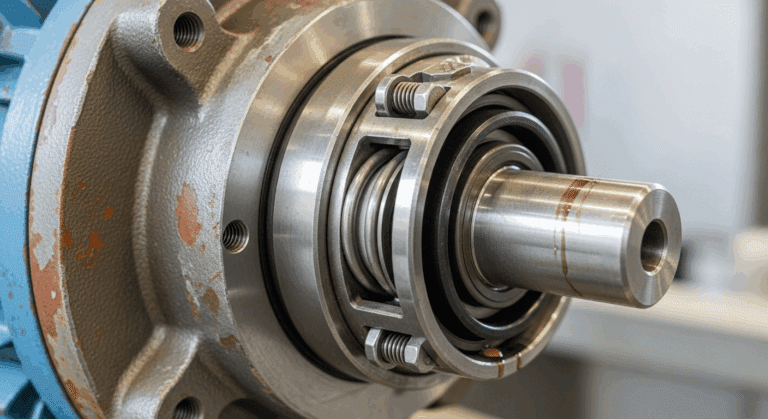

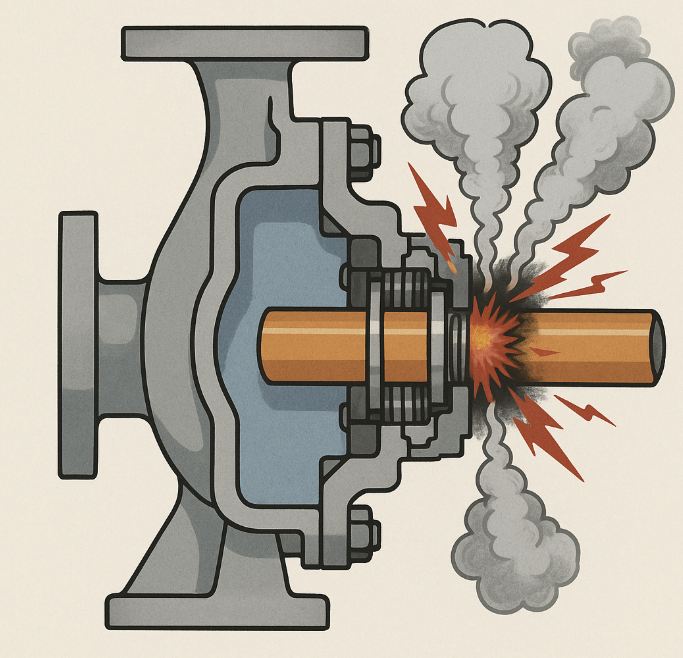

A shop that burns through three lapping machine motors in six months has a process discipline problem, not an equipment problem. I have seen this exact scenario play out — abrasive slurry solidifying overnight, clogging the impeller, and killing motors one after another. The shop blamed the machine. The real culprit was neglected maintenance around the machine. That distinction between machine capability and process discipline runs through every lapping equipment decision a seal shop will make.

Most seal repair shops over-invest in machine automation while under-investing in plate flatness verification. The plate condition determines your achievable accuracy far more than the machine sitting underneath it. For shops evaluating lapping equipment, that priority should shape every specification and budget decision.

Seal Face Flatness Targets

Hard seal faces (silicon carbide, tungsten carbide, ceramic) should read less than three helium light bands for seals with a mean diameter up to 100 mm. Each helium light band equals 0.3 microns, so three bands means 0.9 microns of allowable deviation. High-quality reflective surfaces target less than two light bands — 0.6 microns, or 0.0006 mm.

Why does this matter at the machine selection level? If seal faces separate by roughly two microns or more, visible leakage begins. That gives you almost zero margin. The API 682 standard sets a maximum average liquid leakage rate of 5.6 g/h, and faces out of flat by just a few microns will blow past that number.

The target surface finish for refurbished faces should reach Ra below 0.12 um with parallelism within 2 microns. A Danfoss hydraulic pump restoration achieved Ra 0.0270 um on a basic 15-inch machine — well within specification. The machine was nothing special. The plate and the process were.

Lapping Machine Types

Three categories serve the seal refurbishment market: hand lapping plates, bench-mounted semi-automatic machines, and floor-standing fully automatic systems.

Hand Lapping Plates

A quality cast iron or composite plate with diamond abrasive handles seals up to about 100 mm diameter. A skilled technician achieves three helium light bands consistently — the specification threshold for most seals. The technique demands patience and a trained hand, but the capital investment is minimal. For shops lapping fewer than ten seals per month, hand plates remain a legitimate choice.

Bench-Mounted Machines

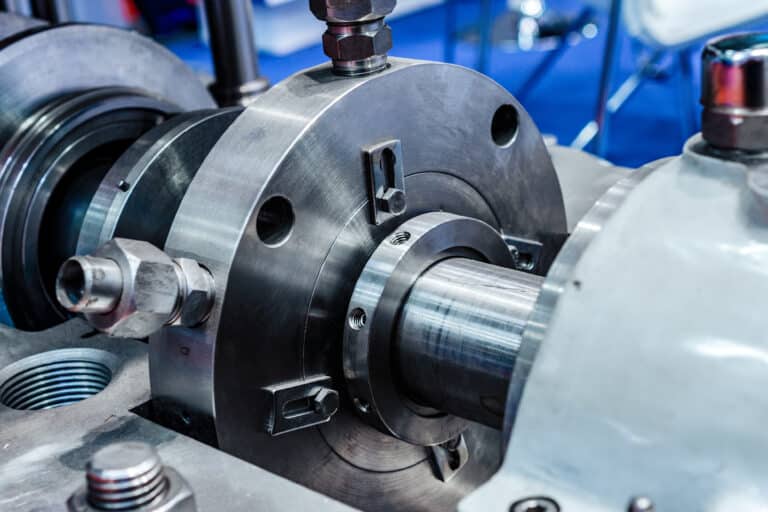

The 15-inch class (381 mm plate) handles seals up to approximately 125 mm diameter. These machines typically run at 70 rpm with a 0.37 kW motor, weighing around 136 kg. They automate the circular motion and diamond dispensing — removing operator variability from the stroke pattern. For shops running 10 to 40 seals per month, bench-mounted units hit the sweet spot of cost versus throughput.

Floor-Standing Automatic Systems

Machines up to 24-inch plates cover seals up to 200 mm diameter, and industrial systems scale to 72 inches for large-diameter applications. Automated diamond dispensing typically sprays 2-second bursts at 20 to 120-second intervals. These systems justify their cost only when volume consistently exceeds 40 to 50 seals per month, or when seal diameters regularly exceed 150 mm.

A mirror-like, high-accuracy surface can be obtained with a simple lapping machine. The difference between a basic bench unit and a fully loaded automatic system is throughput and consistency across operators — not achievable flatness.

Why Plate Condition Outweighs Machine Sophistication

During any lapping operation, the parts being lapped mirror the shape of the lapping plate. A concave plate produces convex faces. A convex plate produces concave faces. No machine automation compensates for a plate that is out of flat. The machine moves the part. The plate determines the geometry.

Lapping plates must be maintained to less than 0.004 mm of flatness deviation. Plate flatness maintenance is the most important skill to master when operating any flat lapping machine — more important than understanding the controls, more important than selecting the right abrasive, more important than the machine brand name.

Plates require checking at least twice daily during continuous use. Correction with conditioning rings runs at a rate of 0.005 to 0.01 mm per 20 minutes. Concave correction runs several times faster than convex correction, so operators must check at five-minute intervals during correction to avoid overshooting. Replace any plate when thickness drops below 3 mm.

I have seen shops spend heavily on automated equipment and then run it with a plate they have never verified with a flatness gauge. The most expensive machine in the world cannot produce a flat seal face on a worn plate. Any conventional lapping machine can be converted to a diamond lapping system simply by replacing the plate and adding a spray unit. That convertibility proves the machine frame is essentially a commodity. The plate is the precision component.

Sizing for Your Shop

Match plate diameter to your largest common seal size. A 15-inch plate handles the majority of pump seals up to 125 mm. Only invest in 24-inch or larger if you regularly refurbish seals above 150 mm diameter.

Lapping pressure varies widely by face material: carbon requires about 100 g/cm2, silicon carbide needs 200 g/cm2, tungsten carbide takes 300 g/cm2, and ceramic demands 600 g/cm2. Your machine must deliver consistent, adjustable pressure across this range.

Common Selection Mistakes

The most expensive mistake is chasing automation while ignoring the plate. I have seen this pattern dozens of times — a shop upgrades to an automatic machine expecting better results, and the seal faces come out no better than before. The old plate went onto the new machine.

Second: underestimating process discipline requirements. One shop destroyed three motors in six months because abrasive slurry solidified overnight in the sump. The fix was not a better machine. It was a daily stirring routine and switching to a mineral seal oil-based lapping vehicle that resisted settling.

Third: buying more machine than the volume justifies. A shop lapping five seals a week does not need automated diamond dispensing. A quality hand plate with proper diamond slurry and a disciplined process will match the flatness results at a fraction of the cost.

Before replacing the seal, check the lapping setup. Before replacing the lapping machine, check the plate.

Making the Right Choice

The decision is simpler than the equipment vendors suggest. Pick a plate diameter that covers your seal range, verify plate flatness twice daily, and match the automation level to your actual monthly volume — not your projected best month. Every dollar saved on machine sophistication buys better plates, better abrasives, and more frequent flatness verification. That is where seal face quality actually lives.