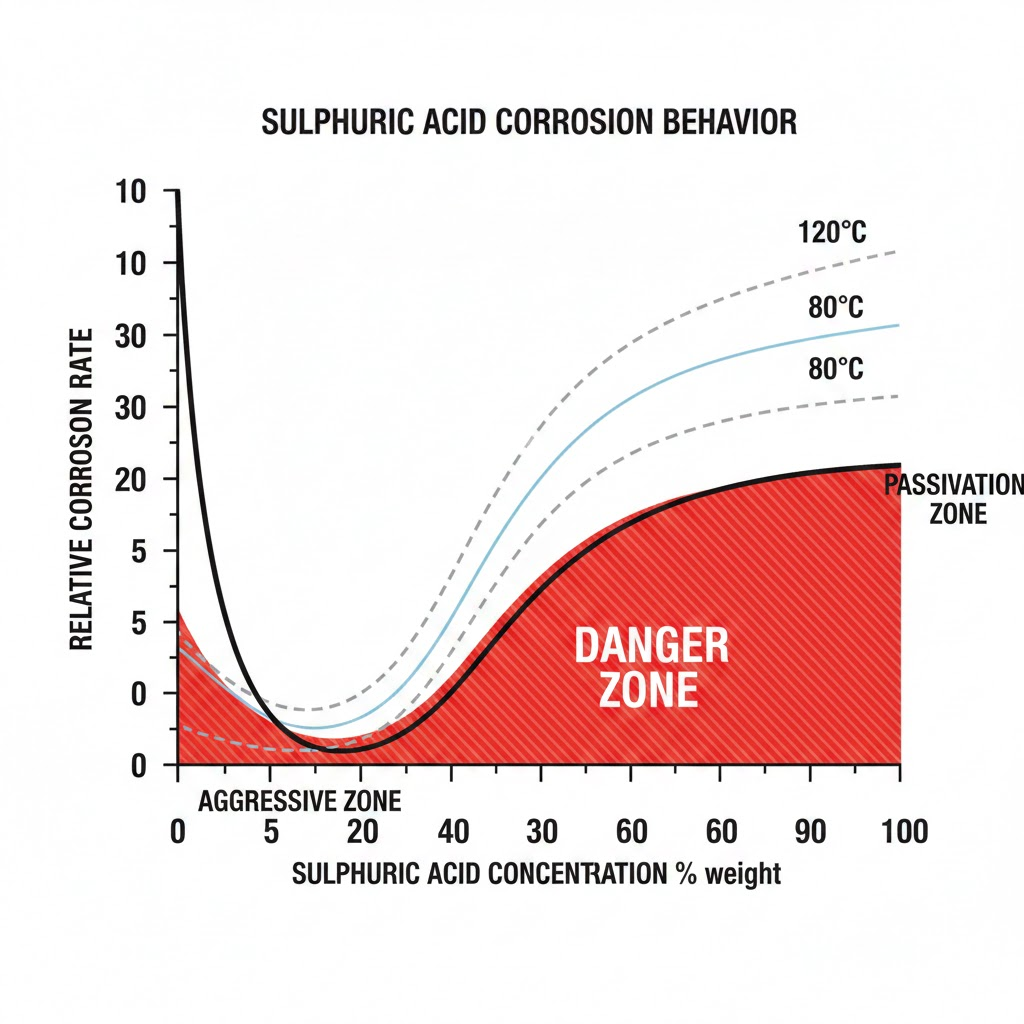

Sulphuric acid behaves counterintuitively: dilute concentrations below 30% attack metals more aggressively than concentrated acid above 90%. At high concentrations, the acid forms protective oxide films on certain metals through passivation. Drop the concentration into the 30-80% range at elevated temperatures, and even high-nickel alloys like Alloy 20 begin to corrode.

This dual corrosion behavior means material selection for mechanical seals depends heavily on the actual concentration you’re handling. Standard “corrosion-resistant” materials that work fine for other acids may fail rapidly in sulphuric acid service.

Why Sulphuric Acid Challenges Mechanical Seals

Concentration is the controlling variable for sulphuric acid seal selection. At low concentrations below 30%, sulphuric acid acts as a strong acid that aggressively attacks most metals. At high concentrations above 90%, the acid shows strong oxidizing properties that allow passivation of certain metals through stable oxide film formation.

The danger zone sits between 30% and 80% concentration, particularly at temperatures above 150F (65C). Corrosion can occur on Alloy 20 if concentrated acid is diluted and reaches this range, even temporarily. Plants handling acid dilution operations face the most severe conditions because the acid passes through the aggressive concentration range during the process.

Temperature amplifies the corrosion rate at every concentration. I’ve seen installations where seals lasted years in ambient 98% acid but failed within months when the same acid was handled at 150F. The most common mistake I see is specifying materials based on concentration alone without considering operating temperature.

Seal Face Materials for Acid Service

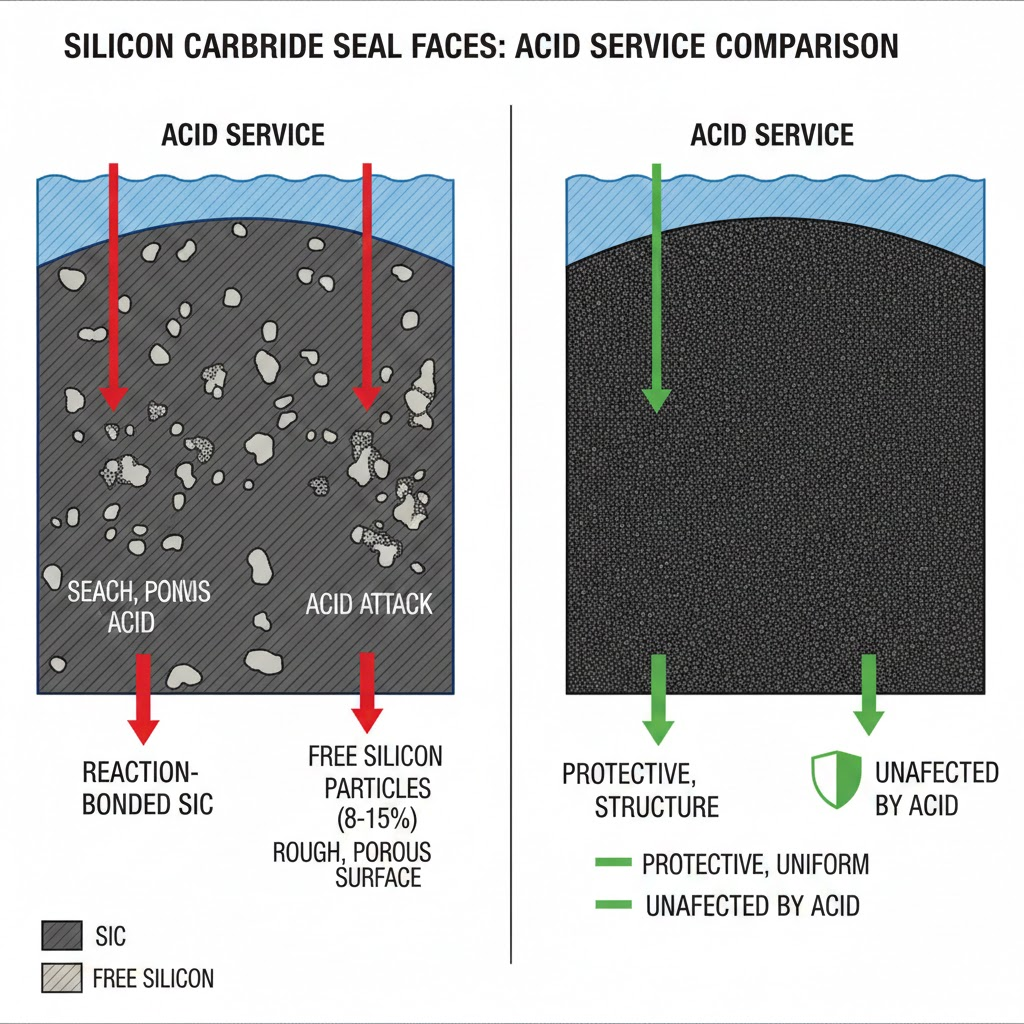

Direct sintered silicon carbide (SSiC) is the preferred face material for sulphuric acid service. Reaction-bonded silicon carbide contains 8-15% free silicon metal that acids attack and leach from the structure. Once the free silicon is removed, the weakened, porous surface acts like a grinding wheel against the carbon mating face.

The pH rule for reaction-bonded SiC is simple: avoid it below pH 4 or above pH 11. Sulphuric acid at any concentration falls well below pH 4, making reaction-bonded SiC unsuitable for this service.

Alumina ceramic also resists sulphuric acid and costs less than silicon carbide. For pure corrosion resistance without abrasive particles in the acid, ceramic faces work well. However, if the acid contains any suspended solids or abrasive contamination, sintered silicon carbide provides better wear resistance. For most acid service where both corrosion and potential abrasion exist, I recommend sintered SiC paired with a carbon-graphite mating face.

Carbon-graphite faces require attention to the impregnant. Resin-impregnated and some metal-impregnated carbons can be attacked by aggressive acids. Specify antimony-impregnated or pure graphite grades for sulphuric acid service.

Elastomer Selection by Concentration

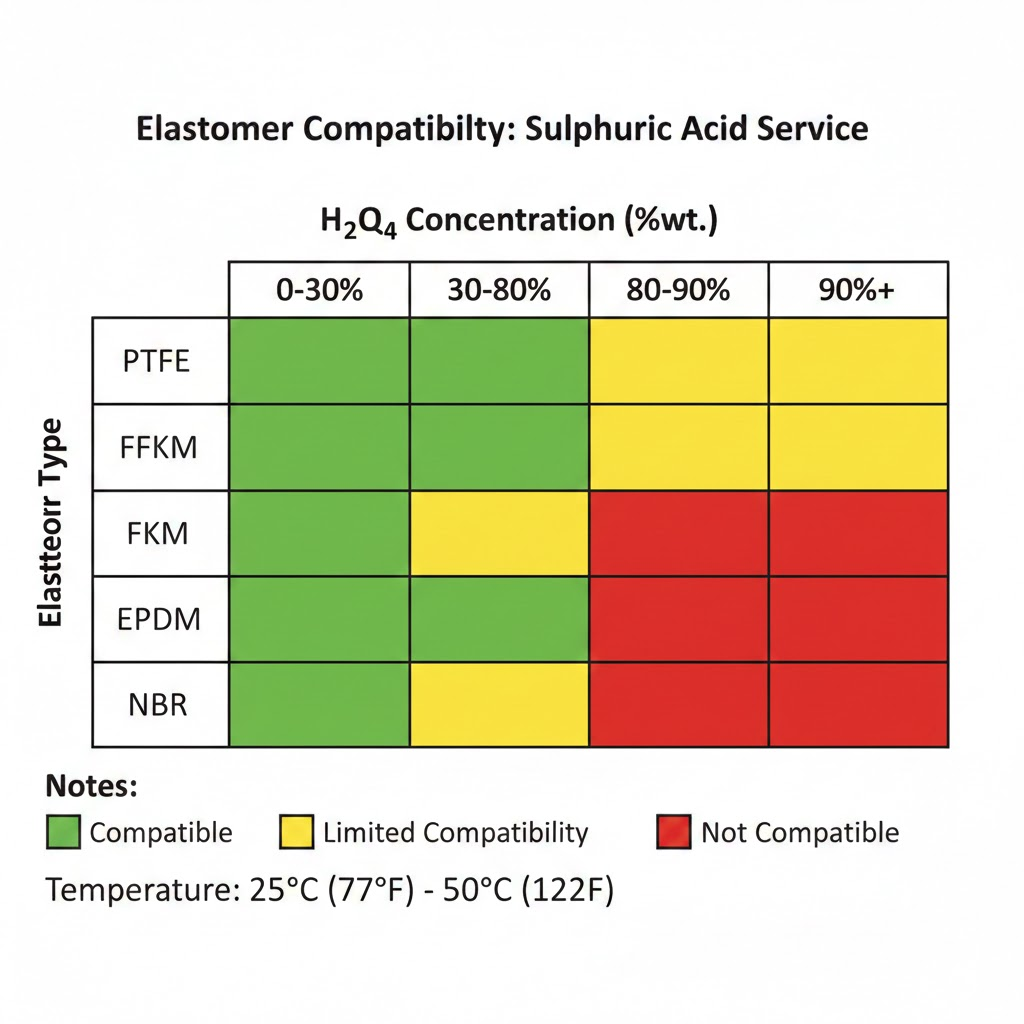

PTFE (Teflon) is the only elastomer material that resists all concentrations of sulphuric acid across the full temperature range encountered during dilution. For O-rings, bellows, and secondary sealing elements, PTFE handles everything from 0% to 98%+ concentration.

The temperature limit for PTFE is 260C (500F), which covers most acid service applications. PTFE bellows seals offer excellent performance in concentrated acids where the bellows material contacts the process fluid directly.

FKM (Viton) works in concentrated sulphuric acid above 90% at moderate temperatures but fails in dilute acid. One practitioner reported that Viton FKM gaskets in ambient 96% acid started to harden and disintegrate after about 12 days. The failure mode varies between FKM compounds, so don’t assume all Viton grades perform the same.

FFKM perfluoroelastomers like Kalrez or Chemraz provide compatibility ratings for 98% sulphuric acid at temperatures up to 150C. These materials cost much more than PTFE but offer better mechanical properties in some configurations. For most applications, PTFE secondary seals provide the best combination of performance and cost.

EPDM and NBR (Buna-N) elastomers are not compatible with sulphuric acid at any concentration. If you find these materials in a seal intended for acid service, the seal was incorrectly specified.

Metal Component Selection

Metal selection depends on concentration and temperature together. For dilute acid below 80% concentration, Alloy 20 is the standard choice. This nickel-iron-chromium alloy with added copper and molybdenum was specifically developed for handling dilute sulphuric acid.

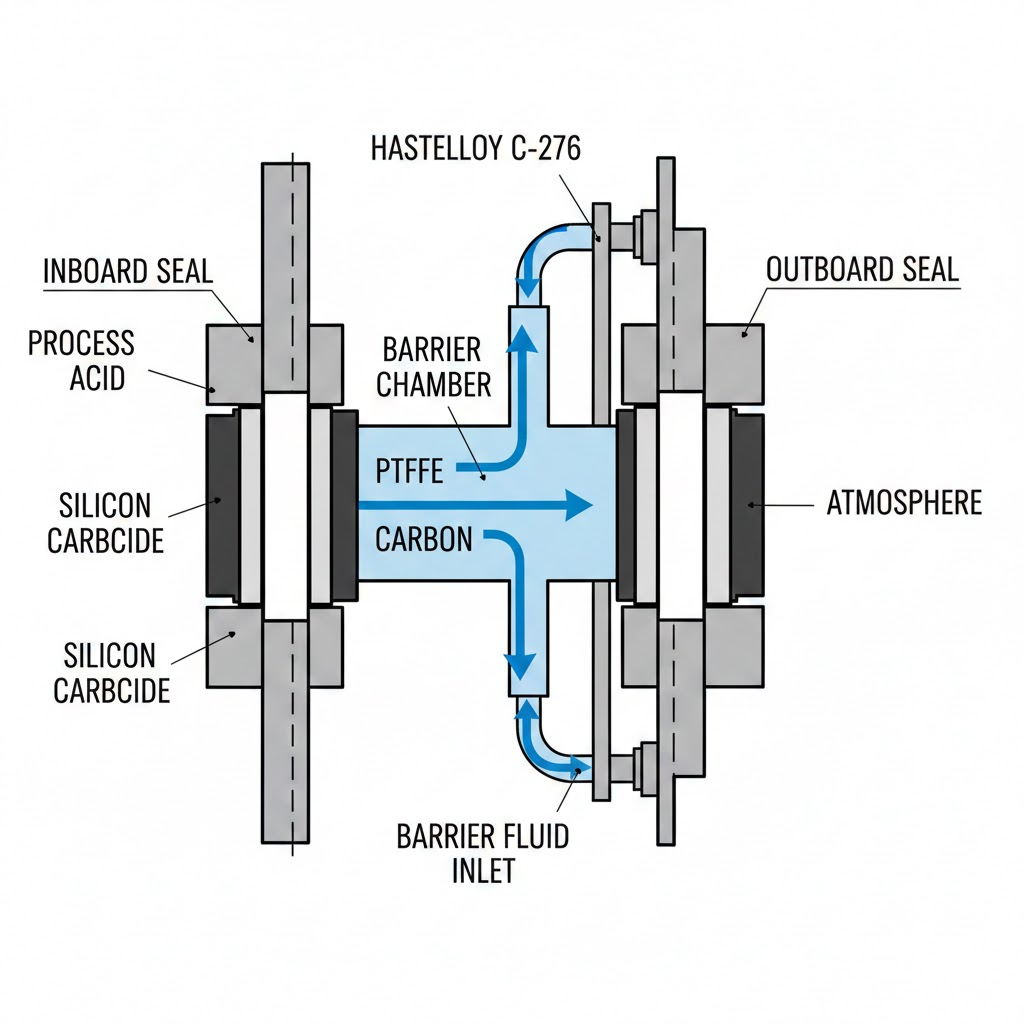

For concentrated acid above 90% or for applications that cycle between concentrations, Hastelloy C-276 provides broader resistance. With approximately 57% nickel and 16% molybdenum, C-276 handles the full concentration range better than Alloy 20.

A peer-reviewed failure analysis documented eight mechanical seal failures and over 30 maintenance events in one year on four sulphuric acid pumps. The root cause was galvanic corrosion combined with metal components that didn’t meet Alloy 20 composition requirements. The actual nickel, molybdenum, and copper content fell below specification.

Before you start installing a seal for acid service, verify the material certifications match the specification. The most common mistake I see is assuming the parts meet spec without checking. When material content is borderline or substandard, the seal may work initially but fail months later as corrosion progresses.

Springs present a particular challenge because standard stainless steel springs corrode in acid. Specify Hastelloy C or Alloy C-276 springs for acid service. Alternatively, use metal bellows seals that eliminate the spring entirely.

Single vs Double Seal for Acid Service

API 682 recommends double seals for high-risk applications involving hazardous or volatile fluids. Sulphuric acid qualifies based on both corrosivity and health hazard.

A double seal configuration with pressurized barrier fluid prevents acid from reaching the atmosphere if the primary seal face fails. The barrier fluid also provides lubrication and cooling independent of the process acid.

According to the American Fuel & Petrochemical Manufacturers, many refiners have chosen dual seals over sealless pumps because the reliability of dual seals in acid service has improved considerably over the past 20 years. Modern dual seal systems with proper materials and barrier fluid selection achieve service lives that make them competitive with sealless alternatives.

For concentrated acid service, PTFE bellows dual seals resist the acid on the process side while the barrier fluid lubricates the outboard seal. This configuration handles the corrosive nature of the acid without relying on the acid itself for seal face lubrication.

Single seals can work for lower-risk acid applications where minor external leakage is acceptable and the acid concentration stays above 90% where corrosion is less aggressive. However, the consequences of seal failure with acid usually justify the additional cost of a dual seal arrangement.

Conclusion

Sulphuric acid seal selection starts with concentration. Dilute acid below 30% and the 30-80% danger zone require the most demanding material selections. Concentrated acid above 90% allows more options due to passivation effects.

Specify direct sintered silicon carbide faces, PTFE elastomers, and Alloy 20 or Hastelloy C-276 metal components based on your concentration range. Verify material certifications before installation. If you skip this step, you may be back replacing the seal in six months when substandard materials fail.

For hazardous acid applications, dual seals provide the reliability and environmental protection that single seals cannot match. The 20-year improvement in dual seal technology makes them a practical choice for most acid service.