At a New Page paper mill, a split mechanical seal on a bottom-entering pulper has been running for 21 years on the original installation – despite a bent shaft, 0.125″ radial movement, and up to 0.030″ stuffing box waviness. That seal replaced traditional packing that had caused continuous leakage, wet floors, and a $60,000 gearbox rebuild.

The difference between that 21-year success and the 6-month failures I see at other mills comes down to understanding what fiber does to seals and selecting accordingly. Fiber-laden fluids demand specific seal configurations, materials, and flush plans that standard mechanical seal selection guidance doesn’t cover.

Why Fiber Destroys Mechanical Seals

Wood fibers attack mechanical seals through four mechanisms that compound each other.

Fiber wrapping is the most visible failure mode. Long fibers, especially from softwood pulp, wrap around the shaft behind the seal faces. This binding accumulates over time, generating heat and eventually pulling the rotating face away from the stationary face. I’ve seen fiber buildup create enough force to crack carbon faces.

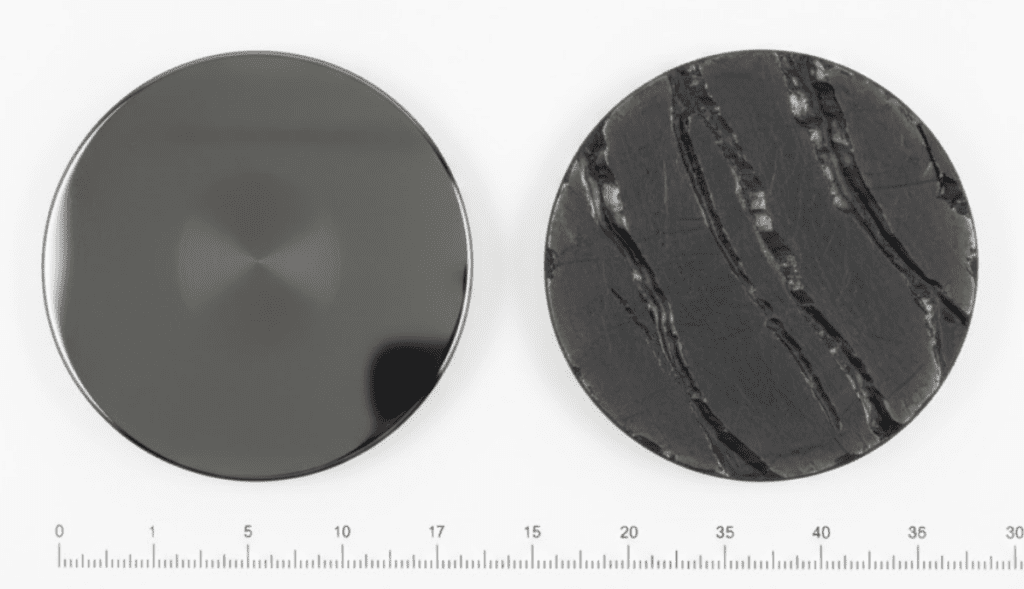

Abrasion occurs at the seal faces themselves. Wood fibers carry silica and other abrasive particles from the original wood. At higher consistencies, these particles act like grinding compound between the seal faces. The wear accelerates when fibers bridge across the seal face gap, holding abrasives in constant contact.

Fiber bridging in the seal chamber restricts the clean flush from reaching the seal faces. Once fibers pack into the stuffing box, no amount of flush flow can clear them without disassembly. This is why seal chamber design matters as much as seal selection.

Chemical attack adds another dimension. Black liquor pumps handle fluids with high pH and elevated temperatures. Bleach tower circulation exposes seals to chlorine dioxide, one of the most aggressive chemicals in the mill. The combination of fiber abrasion plus chemical attack accelerates failure rates.

In agitator applications, solids concentrations reach 15-20% routinely, and some pulp storage agitators handle concentrations as high as 60-75%. Standard pump seals simply cannot survive these conditions.

Seal Selection by Consistency Zone

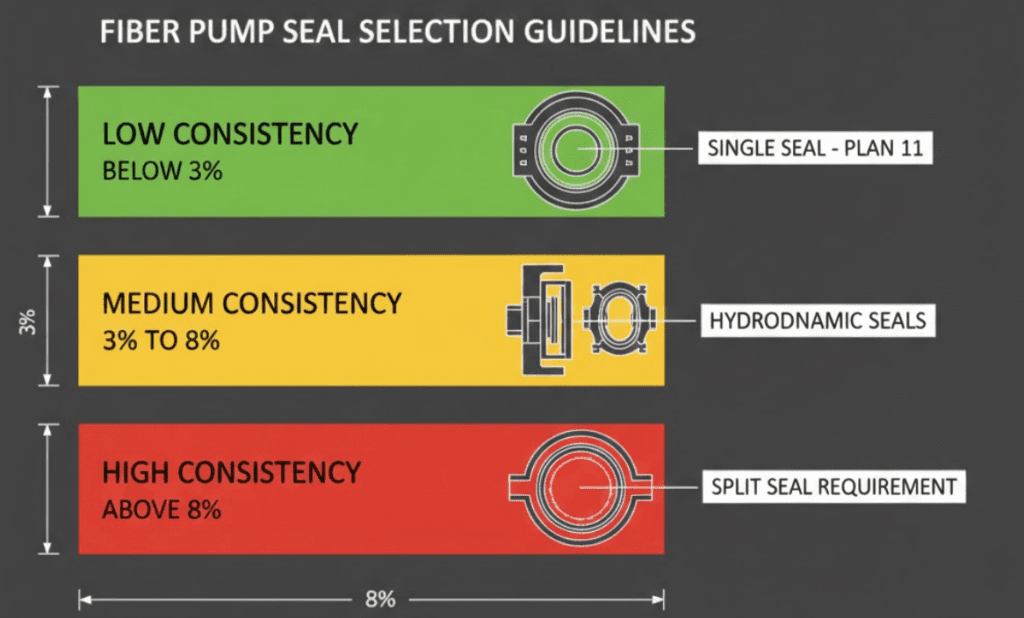

Fiber concentration – measured as consistency (percent fiber by weight) – determines seal requirements more than any other factor.

Low Consistency: Below 3%

At low consistency, fibers remain suspended and flow freely. Single mechanical seals with internal flush (API Plan 11) work reliably for stock transfer and dilute pulp applications. The key requirement is adequate flush flow to prevent fiber accumulation at the seal faces.

Standard elastomer bellows seals handle most low-consistency applications. Cartridge designs simplify replacement and reduce installation errors. Keep face materials matched to the chemical environment – EPDM elastomers for caustic services, Viton where oil contamination is possible.

Medium Consistency: 3-8%

Medium consistency is where most fiber pump seal failures occur. The fiber concentration is high enough to cause rapid wear but not high enough to justify specialized equipment.

Dual seals become the reliable choice here. The outer seal sees clean barrier fluid rather than fiber-laden stock. MTBF improvements of 12-18x are documented when switching from single to dual configurations – one US mill went from 2-3 month seal life to 3 years after the upgrade.

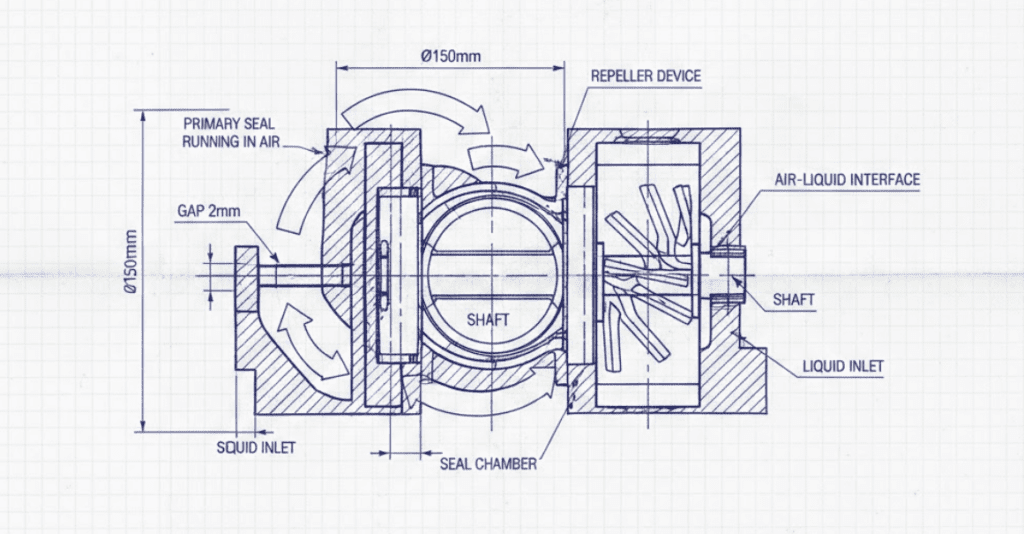

Hydrodynamic seals offer an alternative for medium consistency up to about 6%. These designs use a repeller device to evacuate liquid from the seal chamber, creating an air-liquid interface. The secondary seal runs in air rather than process fluid. This approach eliminates fiber contact with the dynamic sealing surfaces during operation, though it requires 0.37-3.7 kW of additional power depending on pump size.

High Consistency: Above 8%

Above 8% consistency, centrifugal pumps reach their handling limits (maximum around 10% for most designs). Chip feed pumps pushing 15% consistency require positive displacement designs with specialized sealing.

Split seals become essential for high-consistency applications where equipment disassembly is difficult. The 21-year pulper seal mentioned earlier was a fully split design with compression ring rubber bellows – it could be replaced without removing the pulper rotor.

For agitators handling 15-75% solids, split seals with oversized clearances and external flush are standard. One Canadian mill ran a Type 37FS split seal on a demanding agitator for 16 years without a single seal-related shutdown.

Face Materials and Elastomers for Fiber Service

Material selection balances abrasion resistance against chemical compatibility.

Silicon carbide (SiC) is the default hard face material for fiber service. With a Mohs hardness of 9.5 – second only to diamond – SiC resists abrasive wear from wood fibers better than any practical alternative. For fine abrasives combined with corrosive chemicals, SiC/SiC hard-hard face material combinations outperform carbon-SiC pairings.

Tungsten carbide (WC) offers better impact resistance for applications with large particles or significant vibration. In pulpers where debris strikes the seal, tungsten carbide survives impacts that would chip silicon carbide. However, cobalt-bonded tungsten carbide grades have lower corrosion resistance than SiC.

For elastomers, EPDM handles the alkaline environment of most pulp mill applications – caustic, bleach, steam, and hot water. Temperature range extends from -45C to 145C. EPDM costs roughly 1/8 of Viton while providing superior performance in these services.

Viton (FKM) is necessary only where oil or fuel contamination occurs – lubricating oil leakage, fuel-fired equipment, or applications with hydrocarbon exposure. Viton’s temperature range of -20C to 210C exceeds EPDM for high-temperature services.

For chlorine dioxide bleaching applications, standard elastomers fail quickly. Specialty materials like Kalrez (FFKM) double seal life in ClO2 service – documented improvements from 5 months to over 12 months. Some mills use metal bellows seals with titanium components to eliminate elastomer exposure entirely.

Flush Plans for Fiber-Laden Fluids

Proper flush configuration prevents more seal failures than any other single factor. I’ve audited mills where seals were correctly specified but failed within months because the flush system didn’t meet basic requirements.

Plan 11 (internal flush) works only for clean process fluids at low consistency. The moment fiber contamination becomes significant, Plan 11 allows abrasives to circulate through the seal chamber continuously.

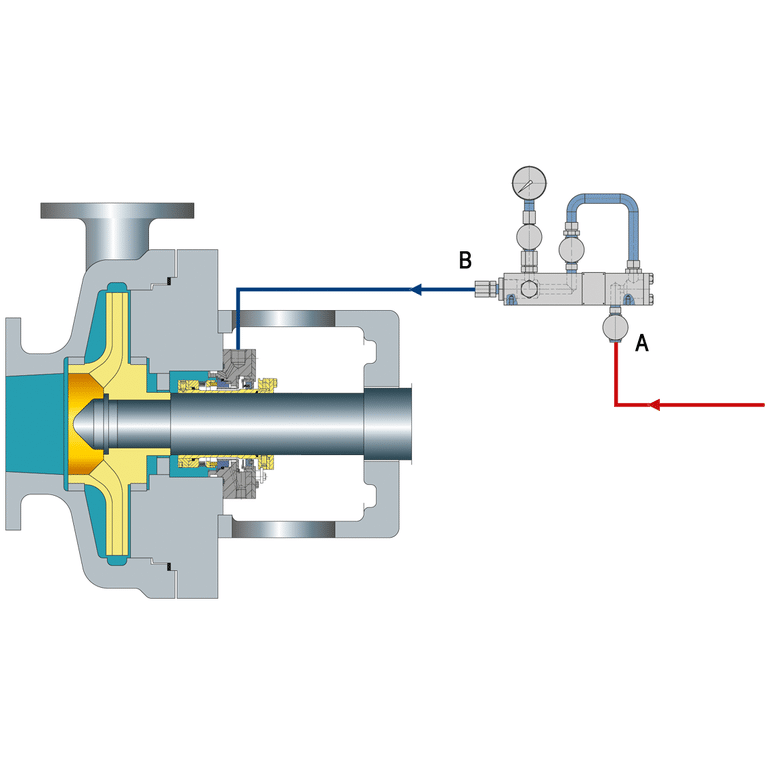

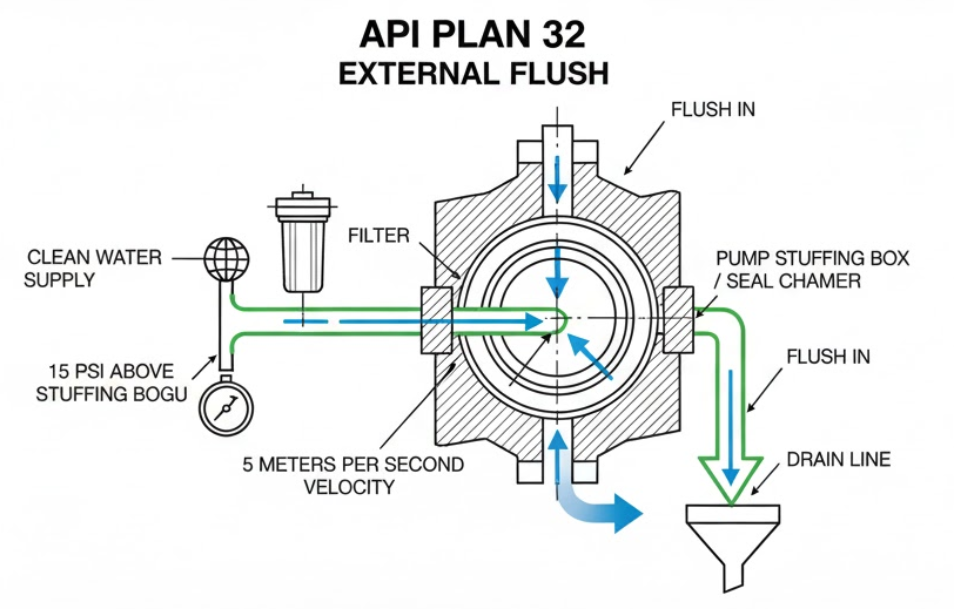

API Plan 32 (external flush) is the standard for fiber applications. Clean water from an external source flushes the seal chamber, keeping fiber away from the seal faces.

The ANSI/HI standard specifies three requirements that most mills fail to meet:

- Flow velocity minimum of 5 m/s to carry solids away from the stuffing box. With wider throat bushings, flow must increase proportionally to maintain this velocity.

- Pressure at least 15 psi (1 bar) above stuffing box pressure to ensure positive flow into the seal chamber. Some sources recommend 25 psi for margin.

- Filtration removing 100% of particles 60 microns and larger. Any debris larger than this accelerates face wear.

A rule of thumb for Plan 32 flow: 1 gpm per inch of seal diameter for 3600 rpm pumps. Adjust proportionally for slower speeds.

The tradeoff with Plan 32 is water consumption. At 3 gpm continuous flow, a single pump consumes 1.5 million gallons annually. Across a mill with hundreds of pumps, this becomes a significant operating cost. Water management systems that monitor and control flush flow can reduce consumption by 60-76% while maintaining seal reliability.

Application-Specific Considerations

Stock Pumps

Stock pumps handling medium-consistency pulp are the bulk of fiber sealing applications. Dual seals with Plan 32 flush provide reliable service. Cartridge configurations speed replacement – one mill reduced seal change time from 8 hours to 2 hours by standardizing on cartridge designs.

Watch for fiber bridging at the throat bushing. If flush pressure is adequate but seal life remains short, the seal chamber geometry may be allowing fiber accumulation between the impeller and seal.

Pulpers and Agitators

Pulpers present extreme conditions: large shaft sizes (75-150mm), low speeds (200-600 rpm), high radial movement, and inconsistent loading. Split mechanical seals are the practical choice because they install without rotor removal.

External flush is mandatory. Size flush connections generously – undersized piping restricts flow and allows fiber to plug the seal chamber.

For bottom-entering pulpers, the seal must accommodate significant axial end play (up to 0.060″ in some designs) while maintaining face contact. Rubber bellows designs handle this motion better than metal bellows.

Bleach Tower Circulation

Chlorine dioxide attacks standard seal materials aggressively. Specify FFKM elastomers (Kalrez, Chemraz) or eliminate elastomers with metal bellows designs.

Temperature fluctuations during bleaching cycles stress elastomers through thermal cycling. Metal bellows seals with titanium components avoid this failure mode entirely.

Dual seals provide a secondary benefit in bleach service: containment of any process leakage before it reaches atmosphere.

Selection Checklist for Fiber Pump Seals

Before specifying seals for any fiber handling pump:

- Document consistency range – not just design point, but maximum expected fiber concentration during upsets

- Identify chemicals present – black liquor, white liquor, ClO2, caustic, bleach all require different elastomer selections

- Measure shaft movement – radial runout, axial end play, and stuffing box face perpendicularity determine seal type feasibility

- Evaluate chamber geometry – throat bushing size affects flush velocity; restricted chambers trap fiber

- Calculate flush requirements – flow rate for 5 m/s velocity, pressure margin over seal chamber, filtration capacity

- Consider maintenance access – if disassembly is difficult, split seals justify their cost premium

- Plan for water management – flush water consumption adds up; monitor and control from initial installation

The mills achieving 7+ year seal life on fiber pumps share one characteristic: they treat seal selection as a system decision – seal type, materials, flush plan, and water management together – rather than picking components in isolation.