Is your compressor a candidate for dry gas seal retrofit? Approximately 99% of new centrifugal compressors ship with dry gas seal technology, yet thousands of legacy machines still run on mechanical seals. The technology is proven. The benefits are documented. But whether YOUR equipment can be converted depends on factors that vendors rarely discuss upfront.

Before you start evaluating vendors, you need to understand what makes a retrofit feasible and what can disqualify your equipment entirely. The most common mistake I see is plants committing to a retrofit project without first confirming their compressor can physically accommodate the change.

Can You Retrofit a Mechanical Seal to Dry Gas Seal?

Yes, most mechanical seal compressors can be retrofitted to dry gas seals, but feasibility depends on three factors: physical compatibility, operating conditions, and infrastructure availability.

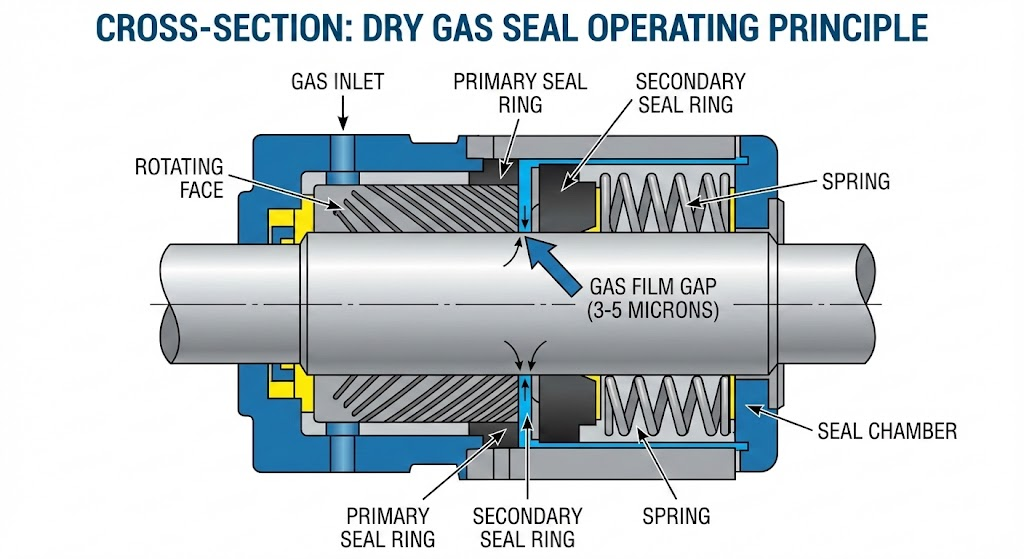

Dry gas seals operate with a microscopic 3-5 micron gap between faces. This non-contacting design eliminates the wear that limits mechanical seal life, but it also means the seal is highly sensitive to contamination and requires precise installation conditions.

One experienced practitioner put it directly: “Retrofitting of DGS is always difficult and should not be considered lightly.” Many compressors continue to operate reliably with wet seals as originally specified. Retrofit makes sense when the benefits justify the engineering effort and infrastructure investment.

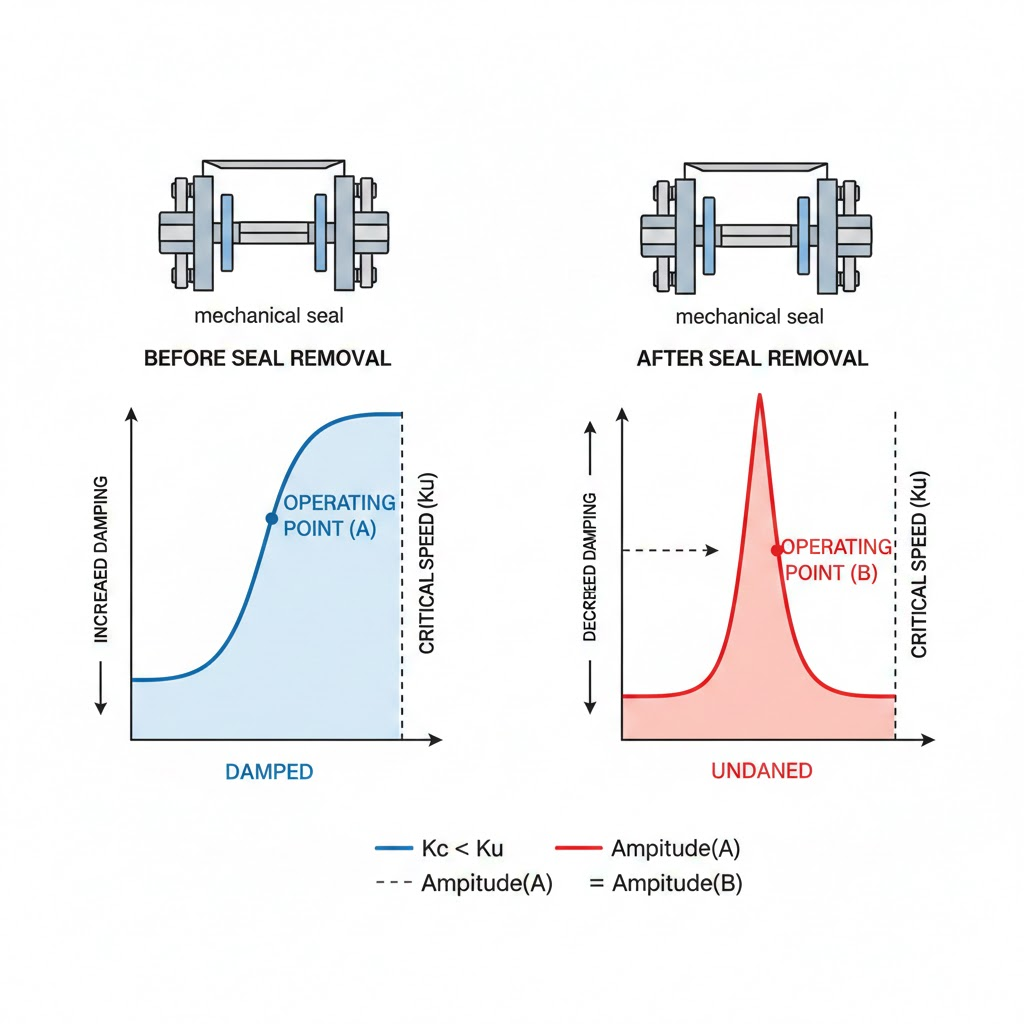

The real risk that vendors rarely mention: removing a mechanical seal changes your rotor dynamics. There have been documented cases where retrofits caused compressors to operate unstably. This happens because the mechanical seal provides damping to the rotor, and removing it can shift the operating point closer to critical speed.

Technical Requirements for Retrofit

Before committing to a retrofit project, verify these technical requirements against your equipment specifications.

Seal Chamber and Shaft Compatibility

Dry gas seals require different physical interfaces than mechanical seals. Your seal chamber must accommodate at least four ports: supply gas, primary vent, secondary vent, and separation gas. Legacy compressors may have non-standard dimensions requiring custom seal cartridges or casing modifications.

Axial space is often the limiting factor. Dry gas seal systems typically require more space than oil seals. If your casing cannot be modified, retrofit may not be viable regardless of other factors.

Rotor Dynamic Analysis

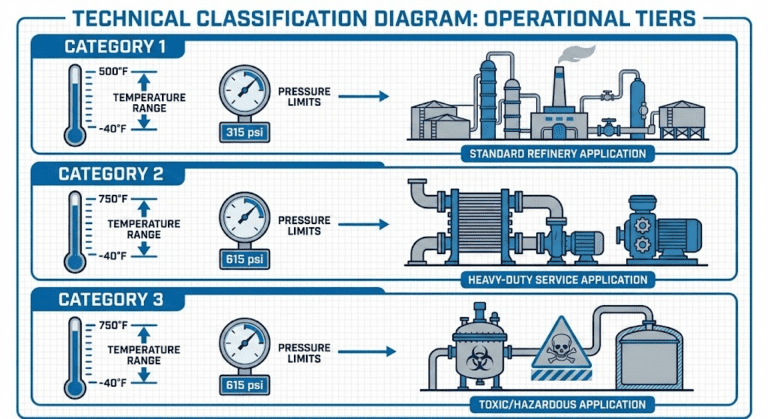

This step is non-negotiable. When you remove the mechanical seal, you change the rotor’s damping characteristics. For any compressor operating above 500 psi discharge pressure, a stability analysis is mandatory.

The solution may require damper bearings or hole pattern seals to restore stability. Budget for this engineering work before finalizing the retrofit decision. If stability analysis shows unacceptable response, that’s a definite no-go.

Operating Condition Requirements

Dry gas seals need minimum lift-off speed to establish the gas film between faces. Below this speed, the faces contact and wear rapidly. During startup and shutdown, compressors typically operate at slow roll speeds around 500 rpm – your seal selection must accommodate this.

Variable-speed equipment requires careful management. Some dry gas seal designs are also unidirectional, which becomes a problem if your application requires reverse rotation.

Infrastructure Requirements

The seal itself is only part of the retrofit. Dry gas seals require support systems that your plant may not currently have.

Gas supply is the critical requirement. API 692 specifies 99.9% efficient filtration down to one micron. The supply pressure must exceed seal chamber pressure by at least 25 psi (or 5-6 bar differential). This often means installing a dedicated barrier gas system with filtration, pressure regulation, and backup supply for startup and shutdown conditions.

According to industry data, 80% of dry gas seal failures trace to contamination. Half of these are hydrocarbon contamination, with solid particulates, chlorides, and free water accounting for the rest. Your infrastructure determines whether you achieve 10+ year seal life or experience repeated early failures.

Here’s a trick that saves time: check your process gas composition before anything else. A re-injection gas compressor in the Middle East experienced seal failure within 20 days of installation. Investigation revealed that C6+ hydrocarbon content had increased since the original analysis five years earlier. The Joule-Thomson cooling effect caused condensation in the seal gas line. The fix required a 15 kW heater in the injection line and upgrading heat trace capacity.

You also need continuous monitoring of pressure, flow, leakage, and temperature. Monthly gas composition analysis is recommended for critical applications. Budget for seal gas panels, interconnecting piping, and conditioning equipment if your process gas is saturated.

When Retrofit Does Not Make Sense

Not every compressor should be retrofitted. Here are the conditions that typically disqualify a project:

Definite disqualifiers:

- Cannot provide clean, dry seal gas at required pressure

- No physical space for gas panel, filtration, and monitoring equipment

- Rotor dynamic analysis shows unacceptable stability response

- Application requires bidirectional rotation with unidirectional seal design

Likely problematic:

- High-pressure hydrogen service above 200 bar. One major oil company avoids dry gas seals for these applications due to documented reliability concerns over 5-year run lengths

- Heavily contaminated process gas requiring extensive filtration

- Saturated gas without budget for conditioning equipment

- Legacy equipment with non-standard dimensions requiring excessive custom engineering

Case-by-case evaluation:

- Existing wet seals operating reliably with acceptable maintenance costs

- Limited operating budget for ongoing infrastructure maintenance

- Lack of personnel trained in dry gas seal operation

If you skip this step, you’ll be back in a week… or 20 days, as the Middle East case demonstrated. Dry gas seal failures account for approximately 48% of compressor downtime. The technology is reliable when properly applied, but it punishes inadequate preparation.

How to Evaluate Your Retrofit Candidacy

Before contacting vendors, gather this information:

Equipment data:

- Seal chamber dimensions (bore diameter, depth, port locations)

- Shaft diameter and material

- Operating speed range (minimum, normal, maximum)

- Discharge pressure and temperature

- Process gas composition (including trace contaminants)

- Rotor dynamic history (any stability issues, critical speeds)

Infrastructure assessment:

- Available space for gas panels and instrumentation

- Clean gas supply options (process gas, nitrogen, plant air)

- Existing monitoring capabilities

- Electrical supply for heaters and controls

Economic justification:

Power savings provide the clearest benefit – dry gas seals consume up to 80% less power than wet seals. Typical wet seal systems require 60-100 kW versus 15-25 kW for dry gas. Lifespan extends from approximately five years to seven to ten years between refurbishments. One documented retrofit increased mean time between refurbishment by 133%, from 3 years to 7 years.

Leakage drops from 40-200 scfm with oil seals to 0.5-3 scfm with dry gas seals. Emissions benefits matter for regulatory compliance in many jurisdictions.

What to Do Next

Request a formal feasibility study from your seal vendor, providing the equipment and infrastructure data listed above. A credible vendor will conduct rotor dynamic analysis and physical integration assessment before committing to a retrofit.

As Raphael Bridon, Manager of Gas Seals and Bearings at Dresser-Rand, noted: “Provided all precautions are taken, dry gas seals may well be the most reliable mechanical seals currently available.” The key phrase is “all precautions.” Proper evaluation before commitment determines whether your retrofit delivers 10 years of reliable operation or becomes a recurring maintenance problem.

Understand the common failure modes before finalizing your decision. A retrofit that succeeds technically but fails operationally due to inadequate support systems delivers worse reliability than the mechanical seals you replaced.