You’ve probably never thought much about mechanical seals—and that’s okay. But if you work with pumps, compressors, or rotating equipment in oil refining, chemical plants, or manufacturing, these tiny components are silently protecting your operations from costly leaks and failures.

Here’s what you need to know: the material you choose for your mechanical seal’s sealing faces directly determines how long your equipment runs without problems, how much you’ll spend on maintenance, and whether your seal survives in harsh chemical environments or extreme temperatures.

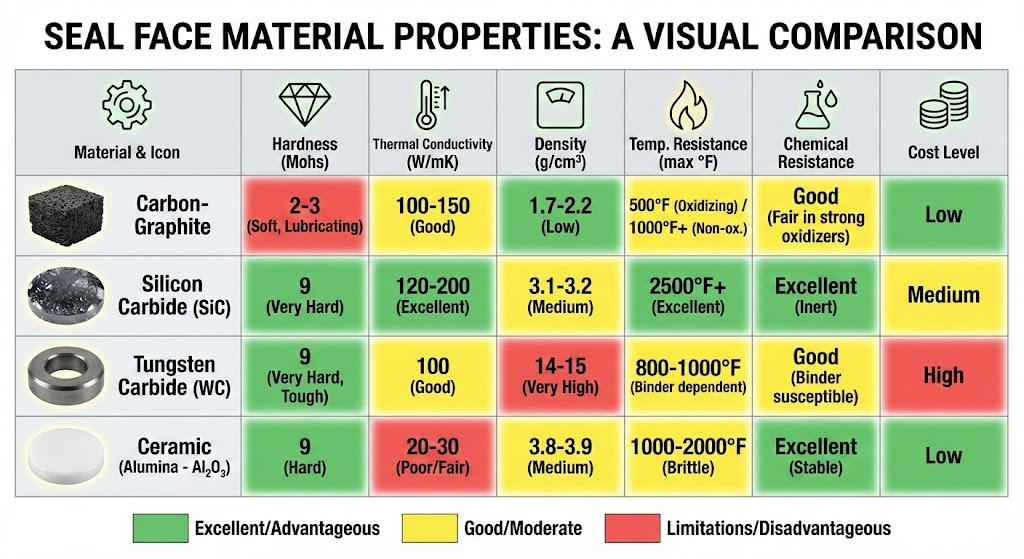

In this guide, you’ll learn about the four main types of mechanical seal face materials—carbon-graphite, silicon carbide, tungsten carbide, and ceramic—and discover which one is right for your specific application.

Main Types of Mechanical Seal Face Materials

Carbon and Carbon-Graphite Materials

Carbon-graphite blends are the workhorse of the sealing world. Most mechanical seals use carbon graphite for at least one of the sealing faces because these materials offer something no other option matches: they’re chemically inert, meaning they resist attack from almost any fluid you’ll pump through them.

Here’s what makes carbon special: it’s soft enough to conform to the hard face and self-lubricating, which means it doesn’t need a separate lubricant to reduce friction. Carbon-graphite materials typically operate safely at temperatures up to about 400°F (200°C) and handle pressures reasonably well. They work beautifully in fresh water applications, light oils, and many chemical solutions.

The catch? Carbon-graphite lacks the hardness of ceramic or carbide materials. This means it wears faster when exposed to abrasive particles suspended in the pumped fluid. If your process contains sand, silt, or other contaminants, carbon faces will degrade more quickly than hard-face materials. They’re also the most economical choice—typically the least expensive option when you’re buying seals.

Carbon-graphite excels when you want simplicity, chemical resistance, and cost-effectiveness. It’s the go-to material for standard applications like water pumping, cooling tower circulation, and light hydrocarbon service.

Silicon Carbide (SiC)

Silicon carbide sounds exotic, but it’s actually created by a straightforward process: fusing silica and coke at extremely high temperatures. The result is a bluish-black ceramic material that’s extraordinarily hard—nearly as hard as diamond on the Mohs hardness scale (rating 9-9.5).

What makes silicon carbide exceptional is its combination of properties. It offers exceptional wear resistance against abrasive particles, maintains its hardness even when temperatures climb to 1,500°F (800°C) or higher, and resists corrosion from nearly any chemical you’ll encounter. The material’s high thermal conductivity (120 W/mK) also means it efficiently dissipates the heat generated at the sealing interface, keeping seal faces cool even at high speeds.

There’s an important distinction: silicon carbide comes in two types. Reaction-bonded silicon carbide has excellent wear and lubrication properties but contains free silicon, which limits its chemical resistance—you should avoid it in applications with strong acids (pH less than 4) or strong bases (pH greater than 11). Direct sintered silicon carbide, on the other hand, offers superior chemical resistance and works reliably across a much wider pH range.

Silicon carbide’s weakness is brittleness. While it’s incredibly hard, it’s also somewhat fragile. If your system experiences shock loads, sudden vibration, or thermal cycling, a silicon carbide face might crack. The material also costs more than carbon-graphite options, so you’re paying a premium for that high performance.

You should choose silicon carbide when you’re facing high temperatures, aggressive chemicals, or severe abrasive conditions. Think oil refining, chemical processing at extreme temperatures, and desalination plants where cost isn’t the primary concern—reliability is.

Tungsten Carbide (TC)

Tungsten carbide is the heavyweight champion of mechanical seal materials—literally. It’s significantly denser than silicon carbide (15.63 g/cm³ compared to 3.1 g/cm³), which immediately tells you it’s heavy and tough.

The real strength of tungsten carbide is its exceptional impact resistance and resilience under shock loading. When you need a seal to survive sudden pressure spikes, vibration, or thermal shock, tungsten carbide delivers. Its high elastic modulus (a measure of stiffness) prevents the seal faces from distorting under pressure, which keeps them properly aligned even in challenging conditions.

Tungsten carbide also boasts excellent thermal conductivity (84 W/mK, which is less than silicon carbide but still quite good) and outstanding resistance to particulate contamination. It simply won’t wear as quickly when your process fluid contains sand or abrasive particles.

The limitations? Tungsten carbide has notable chemistry restrictions. At high temperatures, it’s prone to oxidation (basically, it starts to rust in a sense). It can also react with certain corrosive media, particularly strong oxidizing environments. If your application involves aggressive chemicals or very high temperatures combined with moisture, tungsten carbide might not be the best choice.

Tungsten carbide is your material when you’re dealing with high-pressure systems where shock and vibration are unavoidable—think centrifugal pumps in hydrocarbon service, high-speed compressors, and applications where the sealed equipment experiences frequent pressure fluctuations.

Ceramic Materials (Aluminum Oxide)

Ceramic seal faces are typically 99.5% aluminum oxide, which delivers exceptional hardness and wear characteristics. Ceramics maintain their shape and dimensions even under extreme thermal and mechanical stress, contributing to longer seal life in appropriate applications.

Ceramics offer excellent resistance to most chemicals, acids, and alkalis. They’re also particularly useful in applications where the process fluid must not contact metal—certain pharmaceutical or food processing applications require this level of purity.

But ceramics have significant constraints. The material is brittle and vulnerable to sudden impact or shock. Thermal conductivity is lower than both silicon carbide and tungsten carbide, which means ceramic seal faces generate and retain more heat. This thermal behavior limits ceramics to low-pressure, low-temperature applications (typically under 350°F/175°C). They’re not suitable for high-speed equipment or systems experiencing vibration.

You should consider ceramic only when you need the purity and chemical resistance it offers, and your operating conditions are genuinely mild—low pressure, stable temperature, no shock loads.

How to Select the Right Seal Face Material

Critical Selection Factors

Don’t guess on this decision. Real engineers follow a systematic process to pick the right material.

Start with pressure. Understanding your maximum operating pressure is fundamental. Extremely high pressures (above 3,000 PSI) typically point toward tungsten carbide for its stiffness and distortion resistance. Lower pressures offer more flexibility in material selection.

Next, determine your temperature range. Is it stable, or does it fluctuate? Are you running at room temperature or 1,000°F? Silicon carbide handles extreme temperatures best, but it’s overkill for ambient-temperature applications. Get this wrong and your seal fails prematurely.

Identify the chemical compatibility. This is non-negotiable. Get a detailed analysis of your process fluid’s pH, composition, and whether it contains corrosive or oxidizing agents. Match this against the chemical resistance profile of your candidate materials. SDS (Safety Data Sheet) documentation is your friend here.

Calculate the rotational speed. High-speed equipment (above 3,600 RPM) generates significant heat in the sealing gap. You need materials with high thermal conductivity—silicon carbide or tungsten carbide, not carbon-graphite. Low-speed applications have much more flexibility.

Assess for abrasive particles. Is your process fluid clean, or does it contain sand, scale, or other contaminants? Clean fluids allow you to use softer materials. Abrasive conditions demand hard-face materials like silicon carbide or tungsten carbide.

Industry Standards and Guidelines

API 682 is the gold standard in the petroleum, natural gas, and chemical industries. This American Petroleum Institute standard specifies material combinations and design requirements for mechanical seals used in centrifugal pumps. If you’re selecting seals for any industrial application, familiarize yourself with API 682 guidance.

The standard typically recommends these combinations for different applications:

For clean, low-pressure applications: carbon-graphite paired with stainless steel (simple and economical)

For moderate-pressure hydrocarbon service: carbon-graphite paired with silicon carbide (good balance of cost and performance)

For aggressive or high-temperature service: silicon carbide paired with silicon carbide (maximum wear resistance and thermal stability)

For high-pressure systems with vibration: tungsten carbide paired with carbon-graphite (impact resistance and shock tolerance)

Common Application Scenarios

Oil and Gas Refining: Petroleum refineries operate at high pressures and temperatures with hydrocarbons that vary in composition. Silicon carbide paired with carbon-graphite is the typical choice—it handles the thermal stress and has proven reliability across decades of service. Cost-sensitive operators sometimes use tungsten carbide to reduce initial purchase price.

Chemical Processing: When pumping aggressive chemicals or corrosive solutions, you typically need direct sintered silicon carbide paired with silicon carbide. The chemical resistance of sintered silicon carbide exceeds other options, justifying the premium cost. pH extremes (very acidic or very alkaline) make reaction-bonded silicon carbide problematic—always specify direct sintered.

Water and Wastewater Treatment: Fresh water and moderately contaminated water allow you to use carbon-graphite seals, which are economical and reliable. For heavily fouled wastewater or salt water (desalination), upgrade to silicon carbide or tungsten carbide to handle the abrasive suspended solids.

High-Speed Centrifugal Pumps: When equipment runs at 3,500+ RPM, heat generation becomes critical. Silicon carbide’s superior thermal conductivity makes it the preferred choice. Tungsten carbide is acceptable but requires careful thermal management—inadequate cooling can lead to seal face separation and failure.

Slurry and Abrasive Services: Pumps handling slurries, mining process water, or other abrasive suspensions need hard-face materials. Silicon carbide outperforms tungsten carbide in pure wear resistance, but tungsten carbide’s impact resistance is valuable when particles are large. Many engineers specify tungsten carbide paired with carbon-graphite for slurry service.

Conclusion

Selecting mechanical seal face materials isn’t complicated once you understand the trade-offs. Carbon-graphite offers simplicity, economy, and broad chemical compatibility—it’s perfect for standard applications where cost and ease matter most. Ceramic works when purity is mandatory and operating conditions are mild.

For demanding applications, silicon carbide and tungsten carbide are your tools. Silicon carbide excels in high-temperature, corrosive, or abrasive environments thanks to superior wear resistance and thermal conductivity. Tungsten carbide shines in high-pressure systems with shock loading and vibration, delivering impact resistance and stiffness that silicon carbide can’t match.