When a mechanical seal runs without proper lubrication from the pumped liquid, it generates excessive heat and friction that destroys the seal faces within minutes or hours. You can spot dry running through five key operational symptoms and five distinct visual damage patterns that appear during inspection.

Visual Inspection Signs of Dry-Run Damage

Concentric Scoring or Grooves

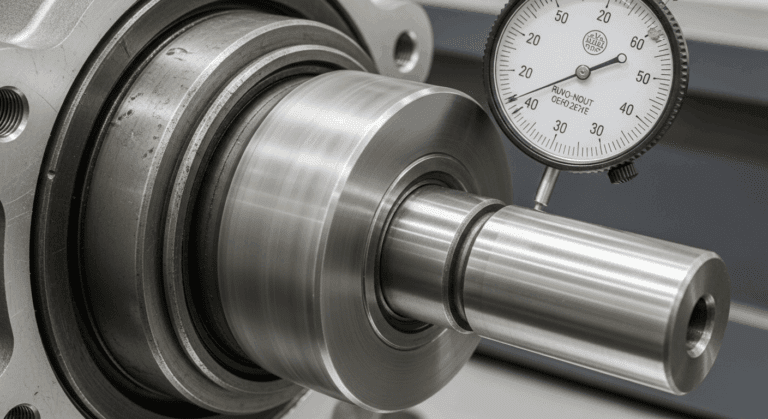

Dry-run damage creates distinct circular scratch patterns on both seal faces. These grooves follow the rotation path and look like the rings on a vinyl record. They form when hard particles or damaged seal material gets trapped between the faces and acts like sandpaper.

The grooves typically measure 0.001 to 0.010 inches deep. You can feel them with your fingernail or see them clearly under good lighting.

These scoring marks are permanent damage. Once formed, the seal faces can’t create an effective seal even if proper lubrication returns.

Discolored or Glazed Faces

Extreme heat from dry running changes the seal face appearance dramatically. Carbon faces turn from their normal matte black to a shiny, mirror-like finish. Silicon carbide faces develop rainbow-colored oxidation patterns similar to heated steel.

The glazed surface feels smooth but can’t seal properly. The heat has changed the material’s structure at a molecular level, destroying its sealing properties.

You’ll often see a gradient of discoloration. The center might be severely discolored while the outer edges show less heat damage.

Radial Cracks (Heat Checking)

Thermal stress causes a network of cracks that radiate outward from the seal face center. These cracks look like a spider web or shattered windshield pattern. They occur when rapid temperature changes create stress that exceeds the material’s strength.

Heat checking appears most commonly on hard faces like silicon carbide or tungsten carbide. The cracks might be hairline thin or wide enough to catch your fingernail.

Blistering or Pitting on Carbon Faces

Carbon seal faces develop small bubbles or craters when exposed to dry-running temperatures. These blisters form when binder materials in the carbon vaporize and create gas pockets. When the blisters pop, they leave behind pits that destroy the sealing surface.

The damage looks similar to a badly corroded metal surface. Pits can range from pinhole size to several millimeters across.

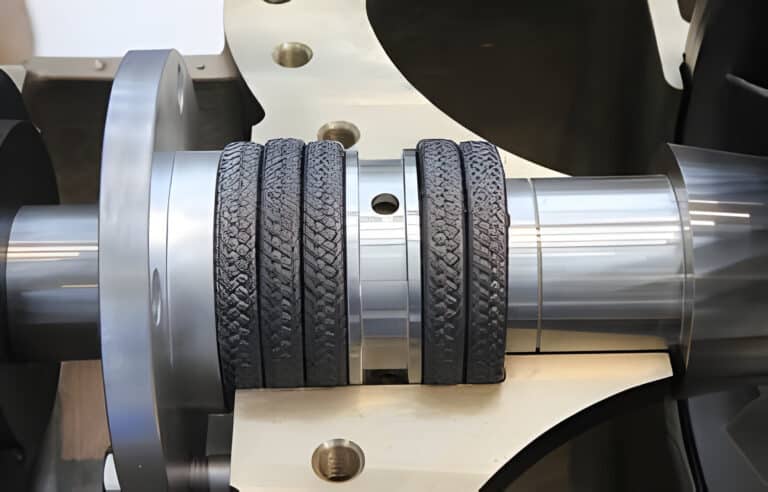

Burned or Deformed Elastomers

O-rings and gaskets show obvious heat damage after dry running. Rubber components turn brittle, crack, or completely disintegrate. They might stick to metal surfaces or leave behind a tar-like residue.

Deformed elastomers lose their circular cross-section and become flattened or twisted. They can’t provide proper secondary sealing even if the primary seal faces remain intact.

The damage often includes a burnt rubber smell that lingers in the pump housing. You might find pieces of elastomer throughout the seal chamber.

Operational Symptoms of Dry Running

Overheating

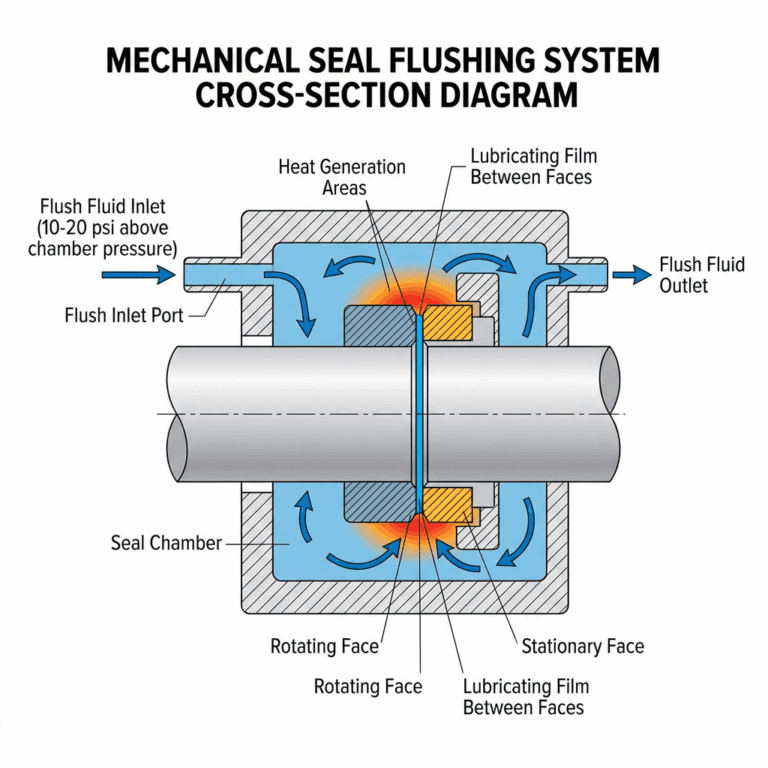

The pump’s seal area will become dangerously hot to the touch within minutes of dry running. Normal mechanical seals rely on the pumped liquid to carry away heat generated by friction between the rotating and stationary faces. Without this cooling, temperatures can spike above 400°F (200°C) in less than five minutes.

You’ll notice the heat radiating from the seal housing before any other symptom appears. The pump casing near the seal might even start smoking or emit a burning smell.

Unusual Noises

A dry-running seal produces a distinctive high-pitched squealing or screeching sound. This noise comes from metal and carbon faces grinding against each other without the thin film of liquid that normally separates them. The sound is similar to dragging your fingernails across a chalkboard, but louder and more consistent.

You might also hear intermittent popping or cracking sounds. These occur when the seal faces momentarily separate due to thermal distortion, then slam back together.

Performance Drop (Loss of Pressure/Flow)

Your pump’s pressure and flow rate will drop significantly when the seal runs dry. As the seal faces deteriorate, they can’t maintain the pressure differential between the pump’s high-pressure side and atmosphere. This creates an internal recirculation path that bypasses the pump’s discharge.

You’ll see pressure gauges dropping steadily while flow meters show reduced output. The pump might struggle to maintain even 50% of its rated performance.

Increased Power Draw

A dry-running seal causes your pump motor to work harder and draw more electrical current. The extra friction between unlubricated seal faces creates additional resistance that the motor must overcome. You’ll see amp readings climb 10-20% above normal operating levels.

This increased power consumption shows up immediately on amp meters or motor control panels. The motor might also run hotter than usual due to the extra load.

Rapid Onset of Leakage or Trip

Dry running leads to sudden, catastrophic seal failure rather than gradual deterioration. You might go from zero visible leakage to a major leak within seconds. The seal faces can crack, chip, or completely disintegrate once thermal stress exceeds their material limits.

Many pumps will trip on high temperature or low flow protection before total failure occurs. This automatic shutdown prevents more serious damage but confirms that dry running has already caused problems.