Mechanical seal failures cause the majority of pump downtime. When flush plans are improperly selected, you’re looking at mean time between failures (MTBF) as low as 18-24 months. That’s a lot of unplanned shutdowns.

Single seal flush plans like Plan 11 work well for clean, non-hazardous fluids below 150°C. They’re simpler and cheaper. Dual seal plans like Plan 52 or Plan 53A give you superior containment for hazardous fluids, high-pressure applications, and zero-emission requirements. Plan 53A offers the highest protection through its pressurized barrier fluid system.

Which Single Seal Flush Plans Should You Consider?

Plan 11 covers 50-75% of all seal applications. It’s the default starting point. Plans 21 and 32 handle situations where temperature or fluid conditions push beyond Plan 11’s limits.

Plan 11: When Is Discharge Bypass the Right Choice?

Plan 11 recirculates flow from the pump discharge through a flow control orifice to the seal chamber. It’s simple, reliable, and inexpensive.

Use Plan 11 when your process fluid is clean (no solids), non-polymerizing, and runs below 150°C (300°F). You also need adequate vapor margin, roughly 345 kPa (50 psi) above the fluid’s vapor pressure at seal chamber conditions.

The orifice that controls flow rate should never be smaller than 3 mm (1/8 inch). Go smaller and you’re asking for clogging problems.

I’ve seen plants default to Plan 11 on everything because it’s familiar. That works until you’re dealing with higher temperatures or fluids that flash at seal face conditions. Then you need something more.

Plan 21: When Do You Need Additional Cooling?

Plan 21 is Plan 11 with a cooler added to the flush line. The cooler drops the fluid temperature before it reaches the seal chamber.

This plan makes sense for clean fluids running between 150-230°C (300-450°F). You’re essentially buying back vapor margin through temperature reduction.

The cooler adds cost and complexity, but it’s far simpler than jumping to a dual seal arrangement. If your only problem is marginal vapor pressure, try Plan 21 first.

Plan 32: When Should You Use External Flush?

Plan 32 brings in clean fluid from an external source instead of recirculating process fluid. This is your go-to for hot service above 230°C (450°F) or when the process contains abrasives or contaminants that would destroy seal faces.

The external flush must be compatible with your process fluid and available continuously from startup through shutdown. A general rule: target 1 gpm flow per inch of seal diameter on 3600 rpm pumps. You also want at least 15 ft/s velocity across the throat bushing to keep solids out of the seal face area.

Plan 32 delivers excellent seal life when properly applied. But it requires a dedicated flush source, which adds infrastructure cost. Refineries running heavy oil services often find it worthwhile.

Which Dual Seal Flush Plans Are Available?

Plan 52 handles most unpressurized applications. Plan 53A covers pressurized barrier requirements. Plans 53B and 53C address higher pressure or dynamic pressure tracking needs.

Plan 52: How Does the Unpressurized Buffer System Work?

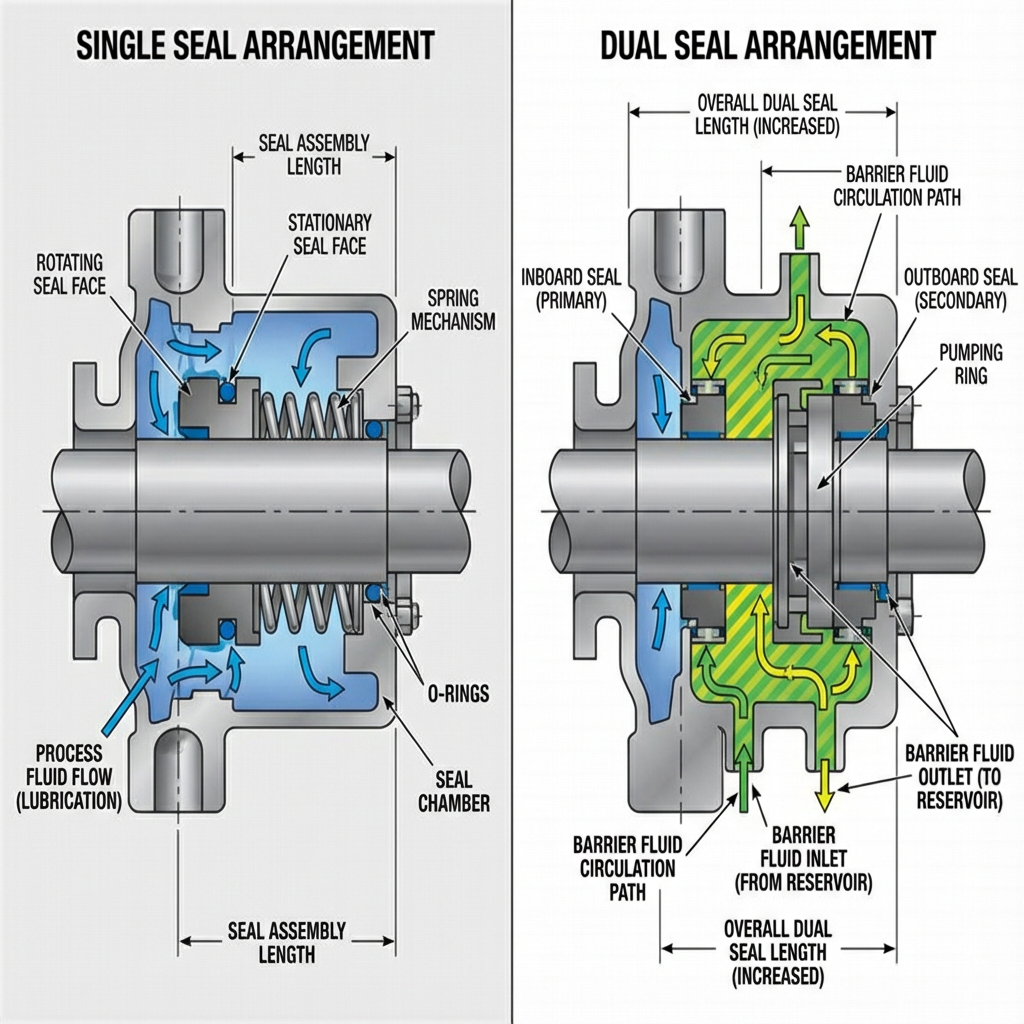

Plan 52 provides buffer fluid from an external reservoir to the space between the inboard and outboard seals. The buffer typically runs at atmospheric pressure or ties into a low-pressure flare header.

Circulation happens through thermosiphon effect during standstill and a pumping ring during operation. The reservoir holds 2-5+ gallons and includes internal cooling coils to remove heat.

This plan excels at collecting any leakage from the inboard seal without letting it escape to atmosphere. VOC-containing services commonly use Plan 52 to meet emission reduction targets.

The catch: Plan 52 accepts some product migration into the buffer fluid. Over time, your buffer becomes contaminated. You’ll need procedures for monitoring, draining, and replacing that fluid. If you need zero process leakage to atmosphere, Plan 52 delivers. But if you need zero contamination of the barrier space, you’ll want Plan 53A instead.

Plan 53A: How Does the Pressurized Barrier System Differ?

Plan 53A uses a pressurized reservoir with the barrier fluid maintained 20-50 psi above seal chamber pressure. A nitrogen blanket typically provides the pressure.

Because the barrier runs at higher pressure than the process, any leakage flows inward across the inboard seal faces. Process fluid never enters the barrier space. The barrier fluid lubricates both seal sets and any that leaks goes into your process, not atmosphere.

API 682 limits Plan 53A to 150 psig due to gas entrainment concerns. Field experience shows you can push to 300 psig with the right barrier fluid and temperatures below 250°F.

One benefit I appreciate: if contamination somehow enters the barrier loop, it stays isolated to that single pump. You’re not dealing with cross-contamination across a central system.

Plan 53B and 53C: When Are Accumulator Systems Needed?

Both plans use closed-loop systems instead of direct nitrogen-to-fluid contact.

Plan 53B uses a bladder accumulator. The nitrogen pushes against a bladder, which pressurizes the barrier fluid without direct contact. This eliminates gas entrainment issues and allows higher operating pressures.

Plan 53C uses a piston accumulator that tracks seal chamber pressure dynamically. As process pressure fluctuates, the barrier pressure follows automatically, maintaining the required differential.

Conclusion

Selecting between single and dual seal flush plans comes down to matching your process conditions to the right level of protection.

Single seal plans handle clean, non-hazardous applications. Plan 11 works for most situations below 150°C with adequate vapor margin. Add a cooler (Plan 21) when temperatures climb to 230°C. Switch to external flush (Plan 32) for hot oil service or abrasive conditions.

Dual seal plans step in when containment matters. Plan 52’s unpressurized buffer collects any leakage from the inboard seal. Plan 53A’s pressurized barrier ensures nothing escapes to atmosphere, period.

Here’s my recommendation: Start with Plan 11 as your default for clean services. It covers the majority of applications at the lowest cost. Move to Plan 21 or 23 when temperature creates vapor margin problems. Jump to Plan 32 when the process itself would damage seal faces.

For hazardous fluids, Plan 52 handles moderate containment needs. When you need zero emissions or your environmental permits demand it, Plan 53A delivers. Always verify your vapor margin calculations and reference API 682 4th edition for detailed specifications.

The right flush plan isn’t the most sophisticated one. It’s the simplest one that reliably meets your process requirements.