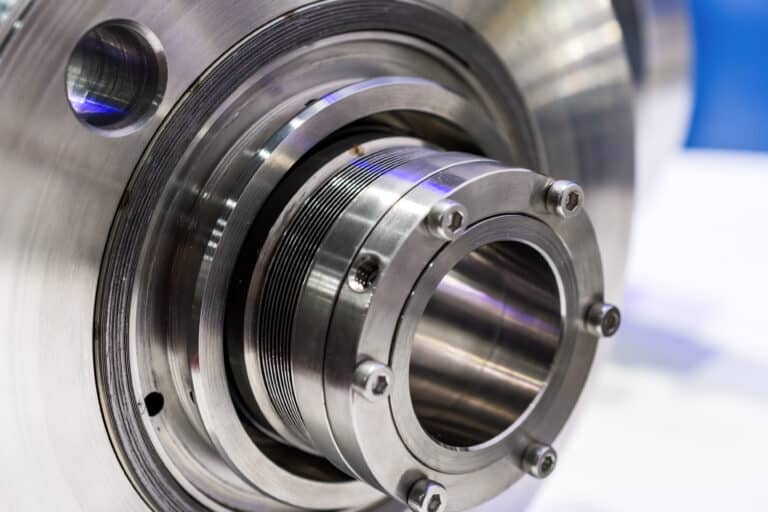

A tandem mechanical seal is a specialized sealing arrangement that consists of two mechanical seals mounted in series within the seal chamber. The tandem design offers a unique set of advantages, including improved safety, increased longevity, and reduced maintenance requirements.

In this blog post, we will delve into the intricacies of tandem mechanical seals, exploring their components, operating principles, and key benefits in various industrial applications.

What Is a Tandem Mechanical Seal

A tandem mechanical seal is a specialized type of mechanical seal that consists of two seals arranged in series within the seal chamber. In this configuration, the two seals operate independently of each other, with the primary seal handling the majority of the sealing function and the secondary seal serving as a backup.

Between the two seals, there is a buffer fluid or barrier fluid that lubricates and cools the seals. This fluid is typically at a higher pressure than the process fluid, preventing any leakage from escaping to the atmosphere. The buffer or barrier fluid is circulated through a separate system, which may include a reservoir, heat exchanger, and pressure control devices.

The use of two seals in a tandem arrangement provides an additional layer of protection against leakage and enhances the overall reliability of the sealing system.

Tandem mechanical seals are commonly used in industries such as oil and gas, chemical processing, and pharmaceuticals, where the process fluids may be hazardous, toxic, or environmentally sensitive. They are also employed in high-pressure applications or in situations where the consequences of seal failure are severe.

How Tandem Mechanical Seals Work

In a tandem mechanical seal arrangement, the two seals are positioned one behind the other, with a buffer fluid or barrier fluid between them. The fluid is typically introduced at a pressure higher than the process fluid, creating a positive pressure gradient across the seals. This configuration allows the tandem seal to effectively isolate the process fluid from the atmosphere.

The primary seal, which is the seal closest to the process fluid, acts as the main sealing component. It is responsible for containing the process fluid and preventing leakage. The secondary seal, located behind the primary seal, serves as a backup in case the primary seal fails. If any leakage occurs past the primary seal, it is collected in the buffer fluid between the two seals.

The buffer fluid between the seals plays a crucial role in the operation of tandem mechanical seals. It lubricates and cools the sealing surfaces, helping to extend the life of the seals. The pressurized buffer fluid also provides a hydraulic barrier, preventing the process fluid from reaching the atmosphere even if the primary seal experiences a failure.

Functions of Tandem Seals

Providing Redundancy

One of the primary functions of tandem mechanical seals is providing redundancy in sealing systems. By incorporating two seals in a tandem arrangement, the system gains an additional layer of protection against leakage and failure. If the primary seal experiences any issues or degradation, the secondary seal is already in place to maintain the sealing function and prevent fluid escape.

Handling High Pressures

Tandem mechanical seals excel in handling high-pressure applications. The unique design of tandem seals allows them to effectively manage and distribute pressure loads between the two seals. By splitting the pressure burden, tandem seals can accommodate higher pressures than single seals of the same size and material.

Minimizing Contamination

Tandem mechanical seals play a vital role in minimizing contamination in sealing systems. The double-seal configuration creates an additional barrier against contaminants, preventing them from entering the sealed fluid or escaping into the environment. The secondary seal acts as a safeguard, capturing any contaminants that may bypass the primary seal and preventing their intrusion into the system.

Advantages of Tandem Seals

Enhanced Reliability

One of the key advantages of tandem mechanical seals is their enhanced reliability compared to single seals. The redundancy provided by the secondary seal significantly reduces the risk of seal failure and unplanned downtime. Even if the primary seal experiences wear or damage, the secondary seal is already in place to maintain the sealing function and prevent leakage.

Extended Seal Life

Tandem mechanical seals offer the benefit of extended seal life compared to single seals. By distributing the pressure load and sealing duties between two seals, tandem seals experience reduced wear and tear on each individual seal. This load sharing mechanism helps to minimize the stress and heat generation on the sealing faces, ultimately prolonging the life of the seals.

Improved Safety

Tandem mechanical seals contribute to improved safety in sealing systems. By providing redundancy and minimizing the risk of seal failure, tandem seals help prevent leakage of hazardous or toxic fluids into the environment.

Applications of Tandem Seals

Chemical Processing

Tandem mechanical seals find extensive use in the chemical processing industry. They are employed in pumps, mixers, and other rotating equipment handling a wide range of chemicals, from mild to highly corrosive or toxic substances.

Oil and Gas

In the oil and gas industry, tandem mechanical seals are commonly used in pumps, compressors, and other critical equipment. They are designed to handle high pressures, extreme temperatures, and abrasive fluids encountered in upstream, midstream, and downstream operations.

Power Generation

Tandem mechanical seals are widely used in the power generation sector, particularly in pumps and turbines. They play a vital role in sealing steam, water, and other fluids under high pressures and temperatures. The redundancy and reliability provided by tandem seals help prevent leakage and maintain the efficient operation of power generation equipment, ensuring a stable and uninterrupted power supply.

Food and Beverage

In the food and beverage industry, tandem mechanical seals are employed in pumps, mixers, and other equipment handling various food-grade fluids. They are designed to meet stringent hygiene and sanitation requirements, preventing contamination and ensuring product quality.

Pharmaceuticals

Tandem mechanical seals are widely used in the pharmaceutical industry, where product purity and contamination prevention are of paramount importance. They are employed in pumps, mixers, and other equipment handling active pharmaceutical ingredients, solvents, and other critical fluids. Tandem seals provide the necessary sealing integrity and redundancy to maintain a sterile and contamination-free environment, ensuring the quality and safety of pharmaceutical products.