Gland packing and lip seals are two common sealing methods used in rotating equipment across various industries. While both serve the purpose of preventing leaks and contamination, they differ in their design, materials, and applications.

This blog post will explore the key differences between gland packing and lip seals, discussing their unique characteristics, advantages, and limitations.

What Is Gland Packing

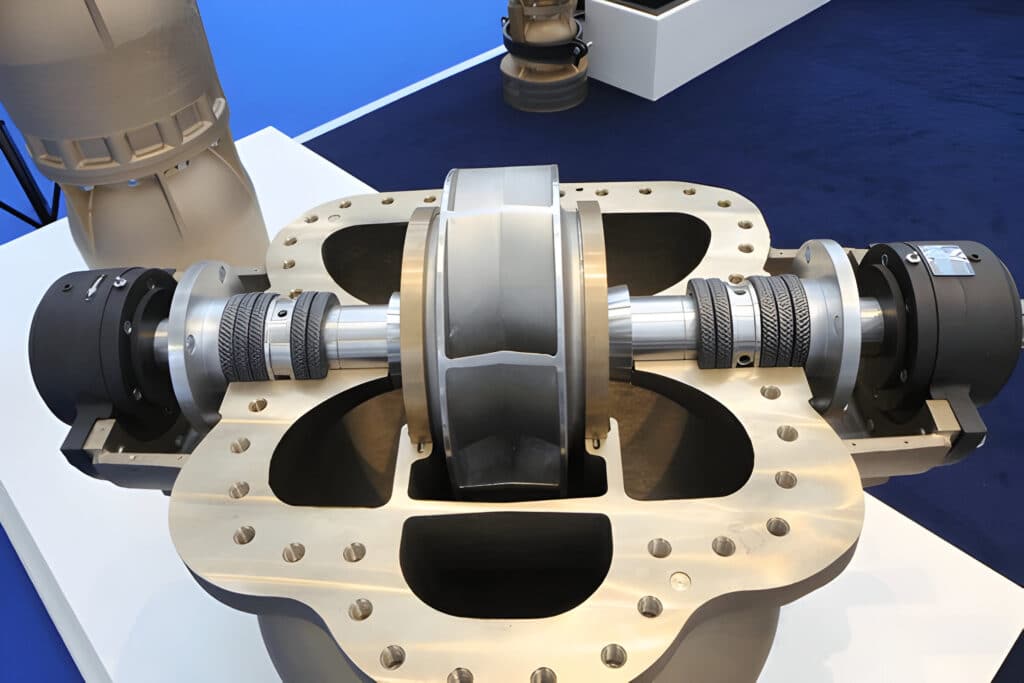

Gland packing, also known as compression packing, is a type of shaft sealing solution commonly used in pumps, valves, and other rotating equipment. It consists of soft, pliable materials such as braided fibers, graphite, or PTFE that are compressed into the stuffing box or gland area surrounding the shaft.

The primary function of gland packing is to create a tight seal around the shaft, preventing fluid leakage and maintaining system pressure. When the packing is compressed by the gland follower, it expands radially, filling the gaps between the shaft and the stuffing box. This compression allows the packing to form a dynamic seal that accommodates shaft movement and thermal expansion.

What Is Lip Seal

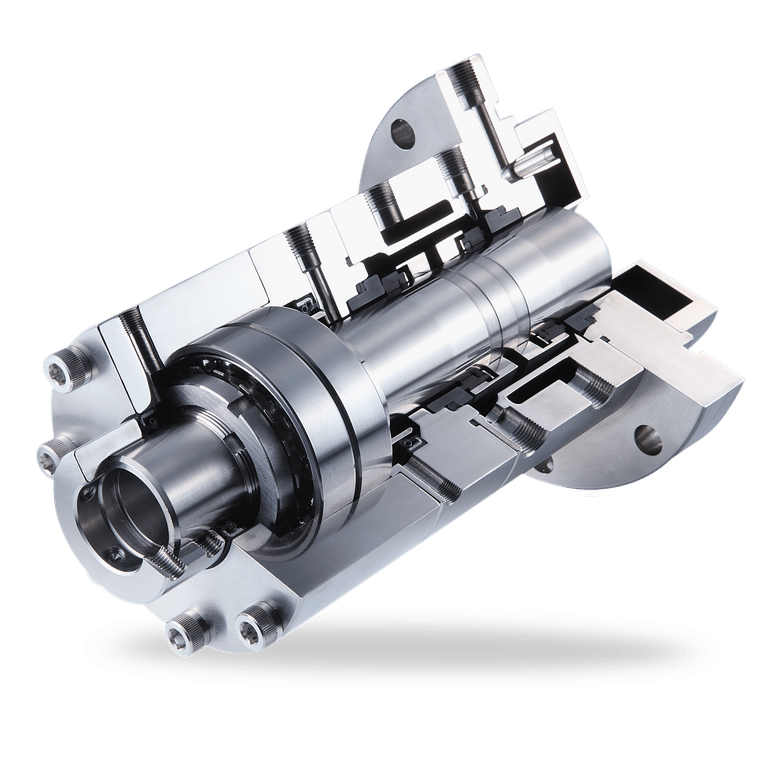

A lip seal, also referred to as a shaft seal or rotary shaft seal, is a type of sealing device used to prevent leakage and contamination in rotary applications. Unlike gland packing, lip seals are self-contained units that consist of a flexible sealing element, typically made of elastomeric materials such as nitrile rubber or fluoroelastomers.

Lip seals feature a circular sealing lip that maintains contact with the rotating shaft, creating a dynamic seal. The sealing lip is designed with a specific geometry and interference fit to provide efficient sealing performance. As the shaft rotates, the lip maintains a thin film of lubricant between itself and the shaft, which helps to reduce friction and wear.

The sealing lip is often supported by a metal case or housing that provides stability and facilitates installation. Some lip seal designs incorporate additional features such as dust lips, which prevent contaminants from entering the sealing area, or spring-loaded lips that enhance sealing effectiveness under varying pressure conditions.

Key Differences Between Gland Packing and Lip Seals

Design

Gland packing consists of braided soft material such as PTFE, graphite, or aramid fibers, which is compressed around the shaft to form a seal.

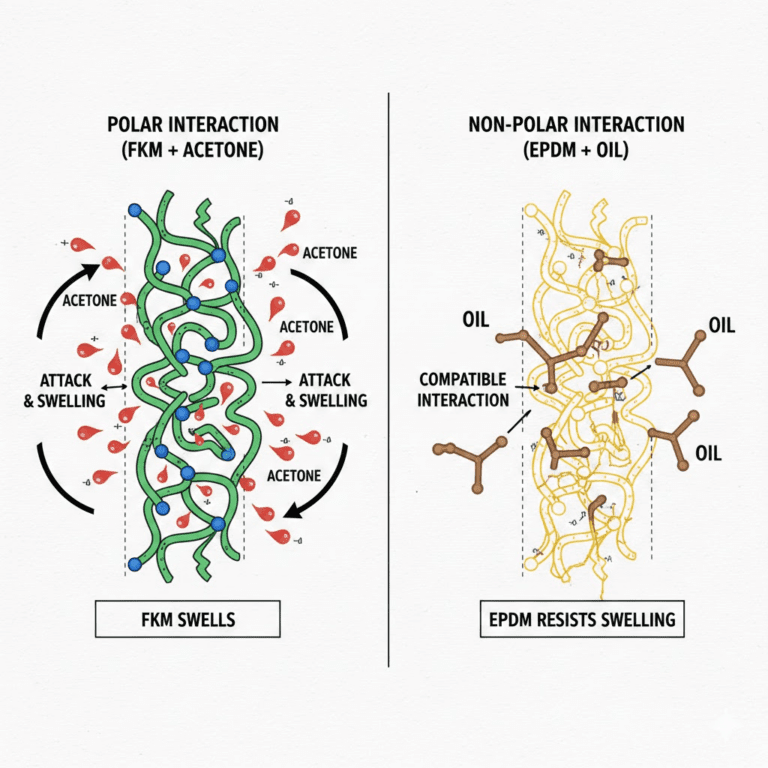

In contrast, lip seals are typically made from elastomeric materials like nitrile rubber or Viton and feature a flexible sealing lip that presses against the shaft.

Installation

Installing gland packing involves cutting rings of packing material to the correct size, staggering the joints, and compressing the packing into the stuffing box using a gland follower.

Lip seals are usually pre-manufactured to specific sizes and simply press-fit into a housing bore or cover plate, making installation quicker and easier.

Maintenance

Gland packing requires regular adjustment to maintain proper compression and prevent leakage. It also needs periodic replacement as it wears.

Lip seals are generally maintenance-free until replacement is necessary due to wear or damage.

Durability

Lip seals typically have a longer service life and can handle higher shaft speeds, but are more susceptible to damage from contaminants or improper installation.

Fluid Types

Gland packing is suitable for a wide range of fluids, including abrasive and high-temperature media.

Lip seals are best suited for lubricating fluids like oil or grease and have limited compatibility with aggressive chemicals or extreme temperatures.

Cost

Gland packing is generally less expensive than lip seals due to its simpler construction and the ability to replace only the packing material rather than the entire seal assembly. However, the total cost of ownership may be higher for gland packing due to the need for regular maintenance and adjustment.

Application Suitability

Gland packing is often preferred for large, slow-rotating shafts, high-pressure applications, and environments with abrasive particles or extreme temperatures.

Lip seals are more commonly used in smaller, high-speed, and lubricant-filled applications such as gearboxes, pumps, and hydraulic motors, where minimal leakage and low friction are prioritized.