Machinery plans are engineered for optimal performance in their designated applications. Plan 21 and Plan 23 are two widely used configurations in the industry, each with distinct characteristics suited for specific operational requirements.

Recognizing the key differences between these plans enables engineers and decision-makers to select the most appropriate configuration for their needs. This article will explore the critical distinctions between Plan 21 and Plan 23, focusing on cooling efficiency, circulation mechanisms, installation requirements, heat exchanger positioning, applications, and maintenance considerations.

What Is Plan 21

Plan 21 is a cooling system design that utilizes a specific configuration of components to effectively regulate temperature within a given space. This plan incorporates a single-stage cooling process, which involves the use of a compressor, condenser, expansion valve, and evaporator. The compressor pressurizes the refrigerant, which then travels to the condenser where it releases heat and condenses into a liquid.

The liquid refrigerant then passes through an expansion valve, reducing its pressure and causing it to evaporate. As the refrigerant evaporates within the evaporator, it absorbs heat from the surrounding air, effectively cooling the space. The cooled air is then distributed throughout the area via a network of ducts and vents.

Plan 21 is known for its simplicity and reliability, making it a popular choice for smaller-scale applications such as residential homes and small commercial buildings. This design is relatively easy to install and maintain, as it consists of fewer components compared to more complex cooling systems.

What Is Plan 23

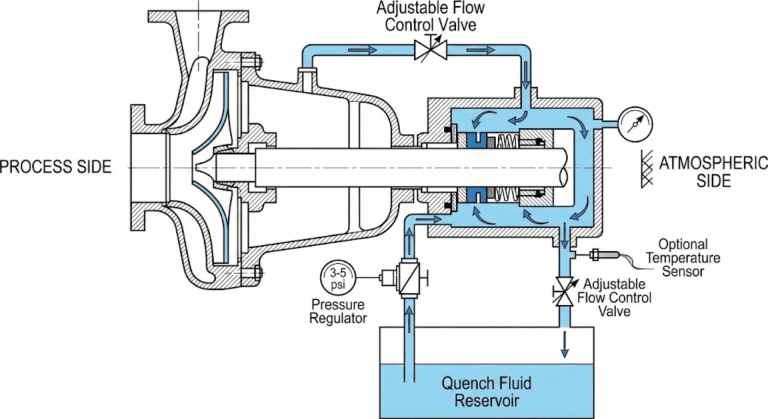

Plan 23 is a more advanced cooling system design that incorporates additional features and components to enhance cooling efficiency and performance. This plan utilizes a two-stage cooling process, which allows for more precise temperature control and improved energy efficiency.

In a Plan 23 system, the compressor operates at two different capacities – high and low. During periods of high cooling demand, the compressor runs at full capacity to quickly cool the space. When the cooling load is lower, the compressor switches to a lower capacity, consuming less energy while still maintaining the desired temperature.

Another key feature of Plan 23 is the use of a variable speed air handler. This component adjusts the speed of the fan based on the cooling needs of the space, ensuring optimal air circulation and minimizing energy waste. The variable speed air handler also contributes to improved indoor air quality by continuously circulating and filtering the air.

Plan 23 systems often incorporate more advanced controls and sensors, allowing for better monitoring and adjustment of the cooling process. These additional features make Plan 23 suitable for larger and more complex applications, such as multi-story buildings, commercial spaces, and industrial facilities.

Difference Between Plan 21 and Plan 23

Cooling Efficiency

Plan 21 and Plan 23 differ in their cooling efficiency. Plan 21 utilizes a single-stage cooling process, which provides adequate cooling for most applications. In contrast, Plan 23 employs a two-stage cooling process, enabling it to achieve higher cooling efficiency and better performance in demanding situations.

The two-stage cooling in Plan 23 allows for more precise temperature control and faster cooling times. This is particularly beneficial in applications with high heat loads or when rapid cooling is required.

Circulation Mechanisms

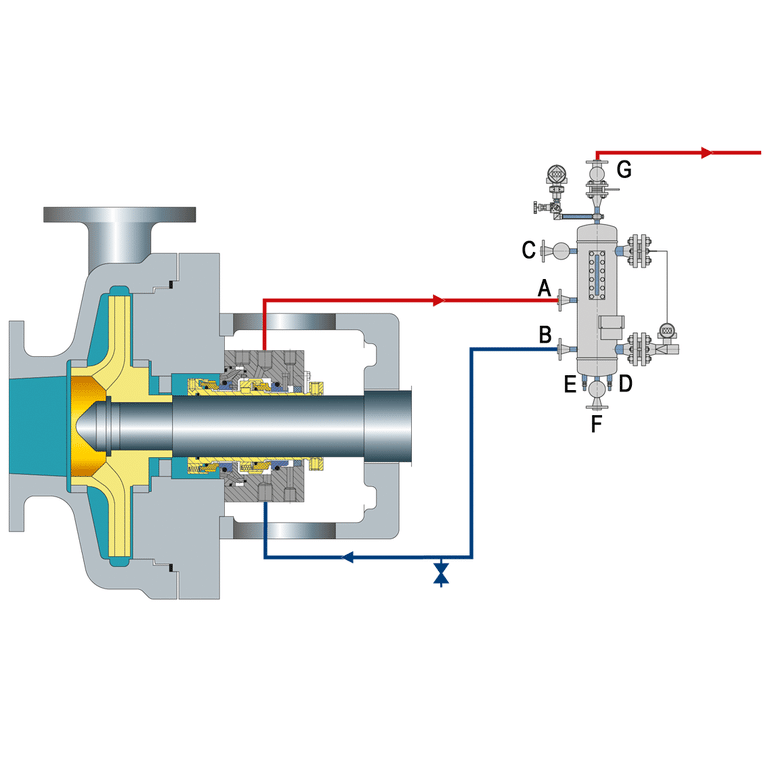

The circulation mechanisms also vary between Plan 21 and Plan 23. Plan 21 uses a standard pump to circulate the coolant through the system. While effective, this single-pump design may experience limitations in terms of flow rate and pressure.

Plan 23, on the other hand, incorporates a dual-pump system. The two pumps work in tandem to provide enhanced coolant circulation. This design offers improved flow rates, higher pressure capabilities, and increased system reliability due to redundancy.

Installation Requirements

The installation requirements for Plan 21 and Plan 23 differ due to their unique features. Plan 21, with its simpler single-stage cooling and single-pump design, generally has more straightforward installation requirements. It can be installed in a wider range of locations and requires less space.

Plan 23, with its advanced two-stage cooling and dual-pump system, has more complex installation requirements. It may require additional space to accommodate the larger components and more intricate piping. Special considerations may be necessary for proper mounting and vibration isolation.

Heat Exchanger Positioning

The positioning of the heat exchangers is another key difference between Plan 21 and Plan 23. In Plan 21, the heat exchanger is typically located in a central position within the system. This allows for equal distribution of cooling to all components.

Plan 23 takes a different approach, utilizing multiple strategically placed heat exchangers. This distributed heat exchanger design enables targeted cooling in specific areas where heat generation is most intense. It helps optimize overall system cooling efficiency.

Application

Plan 21 and Plan 23 are suited for different applications based on their cooling capabilities and features. Plan 21 is ideal for general-purpose cooling in applications with moderate heat loads. It is commonly used in industries such as automotive, manufacturing, and HVAC systems.

Plan 23, with its advanced cooling efficiency and robust circulation, is better suited for demanding applications. It excels in industries that require precise temperature control, high heat dissipation, and reliable performance. Examples include data centers, power generation plants, and industrial processing equipment.

Maintenance

The maintenance requirements for Plan 21 and Plan 23 also differ. Plan 21, with its simpler design, generally requires less frequent maintenance. Regular inspections, coolant level checks, and filter replacements are typically sufficient to keep the system running smoothly.

Plan 23, due to its more complex design, may require more extensive maintenance. The dual-pump system and multiple heat exchangers necessitate additional attention. Regular inspections, coolant analysis, and component replacements may be needed to ensure optimal performance and longevity.