The gap between bearing labyrinth seals typically ranges from 0.010 to 0.030 inches (0.25 to 0.75 mm), depending on the shaft diameter and operating conditions. This tiny space—about the thickness of a few sheets of paper—is critical for preventing contamination while allowing the shaft to spin freely without touching the seal.

Why This Gap Matters More Than You’d Think

Getting this gap right is like setting the perfect distance between two magnets that shouldn’t touch but need to stay close. Too small, and the seal rubs against the shaft, creating heat and wear. Too large, and dirt, moisture, and other contaminants sneak into your bearing, causing premature failure.

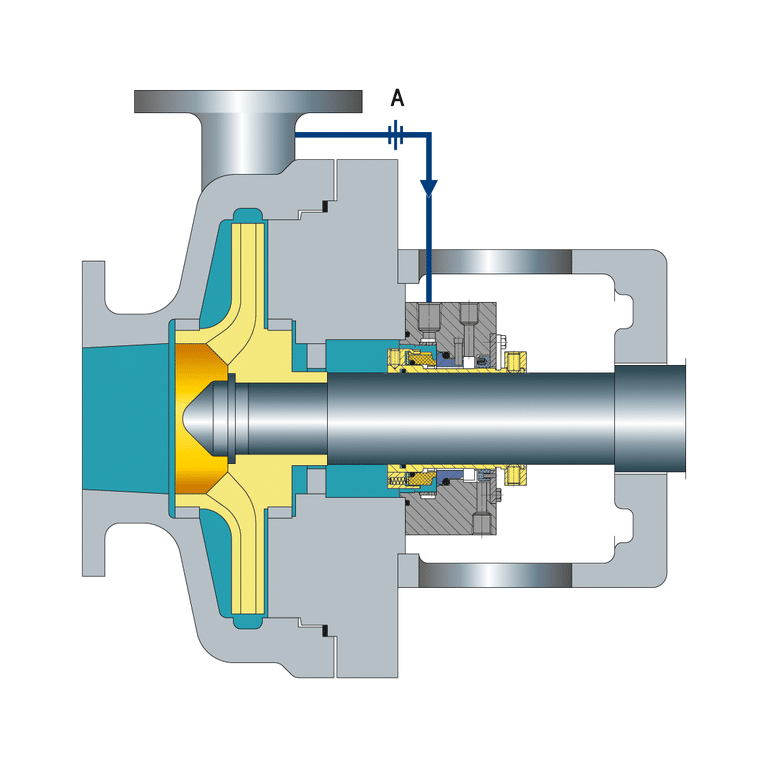

The gap creates what engineers call a “tortuous path.” Picture water trying to flow through a maze—it loses energy at every turn and eventually gives up. That’s exactly what happens when contaminants try to pass through a properly gapped labyrinth seal.

Standard Gap Measurements by Shaft Size

For most industrial applications, here’s what you’re looking at:

Shafts under 2 inches (50mm) need a gap of 0.010-0.015 inches. This tight clearance works because smaller shafts have less thermal expansion and vibration.

Shafts between 2-6 inches (50-150mm) require 0.015-0.020 inches. This middle range covers most pump and motor applications you’ll encounter.

Shafts over 6 inches (150mm) need 0.020-0.030 inches or more. Larger equipment experiences more thermal growth and deflection during operation, so it needs extra breathing room.

Factors That Affect Your Gap Setting

Operating temperature

A shaft that starts at room temperature might grow 0.005 inches when it reaches operating temperature. If you didn’t account for this thermal expansion, your perfect gap becomes metal-on-metal contact.

Shaft speed

At high speeds (over 3,600 RPM), you need slightly larger gaps because the shaft tends to whip or orbit slightly within its bearings.

Environmental conditions

In dusty environments, you might run tighter gaps to keep particles out. In clean, controlled environments, you can go slightly larger for less friction.

How to Measure and Set the Gap Correctly

Start by using feeler gauges at four points around the seal—top, bottom, and both sides. The gap should be consistent within 0.002 inches at all points.

Check for shaft runout before setting your gap. If the shaft wobbles more than 0.002 inches, fix that first. A wobbling shaft makes it impossible to maintain proper clearance.

Always measure with the equipment at rest and at room temperature. Then calculate how much the shaft will grow when hot. Add this thermal growth to your cold clearance to get your installation gap.

Common Problems From Incorrect Gaps

Too tight

You’ll see blueing on the shaft from heat, grooves worn into the metal, and sometimes even smoke during operation. The bearing temperature spikes, and you might hear a high-pitched squealing.

Too loose

Contamination slowly enters the bearing housing. You won’t notice problems immediately, but bearing life drops by 50% or more. Oil leakage increases, and you’ll find dirt in your lubricant samples.

FAQs

Can I use RTV silicone to seal larger gaps in labyrinth seals?

No, adding sealants defeats the purpose of a labyrinth seal. The seal needs its designed gap to function properly. If your gap is too large, you need to replace the seal or machine it to the correct dimensions.

How often should I check labyrinth seal clearances?

Check clearances during scheduled maintenance shutdowns, typically every 6-12 months for critical equipment. High-speed or high-temperature applications need more frequent checks, while low-speed, clean environment equipment can go longer between inspections.

What’s the difference between radial and axial clearance in labyrinth seals?

Radial clearance is the gap between the seal and shaft diameter, while axial clearance is the gap between the seal faces and any shoulders or thrust surfaces. Most discussions about “gap” refer to radial clearance, which is more critical.

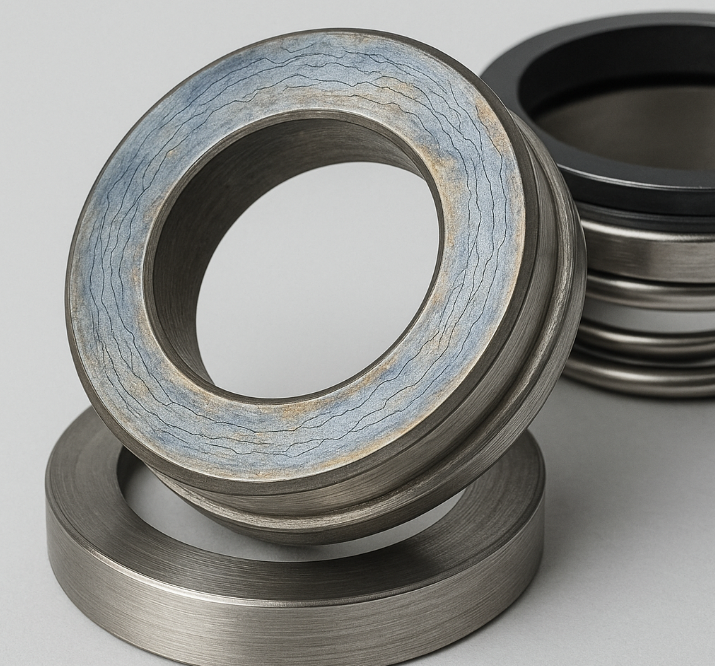

Why do some labyrinth seals have grooves while others are smooth?

Grooved designs create more turbulence and pressure drops, making them more effective at stopping contamination. Smooth designs work better at high speeds where grooves might create unwanted air currents that actually pull contaminants in.