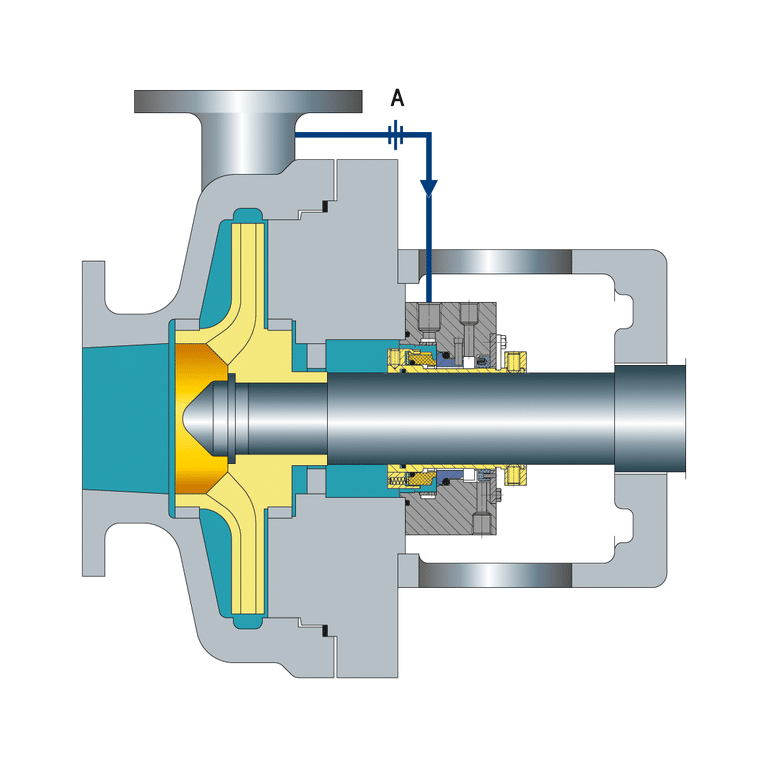

When a mechanical seal burns out after just a few months of operation, the root cause often comes down to one critical number: the PV value. I’ve seen maintenance teams scratch their heads over premature seal failures, only to discover they’d been running their equipment way beyond its PV limit.

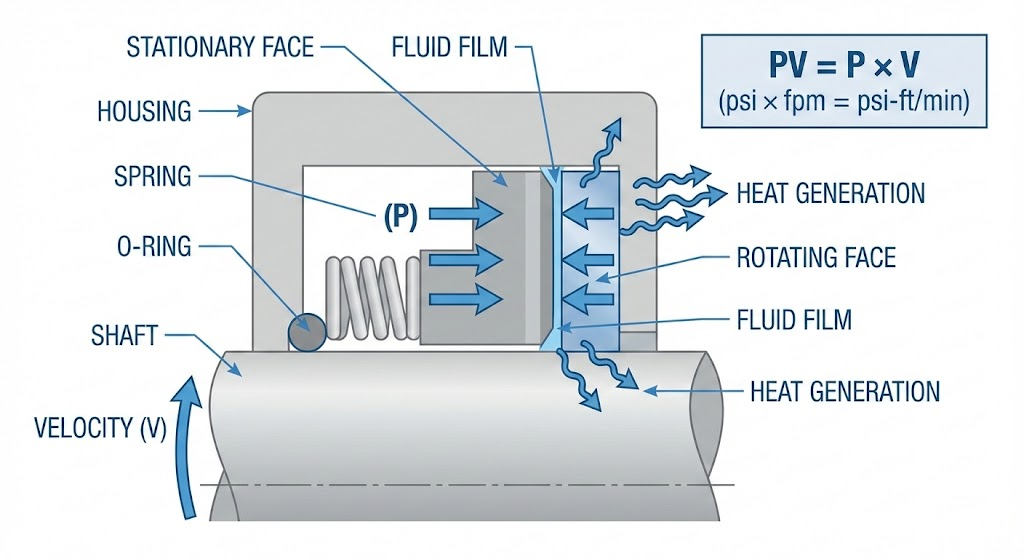

PV value is the product of system pressure (in psi) multiplied by surface velocity (in feet per minute) at the seal interface. It’s measured in psi-ft/min and tells you how much stress your seal faces during operation. Think of it as a heat and wear indicator rolled into one simple calculation.

What Does PV Stand for in Mechanical Seals

What is the Basic Definition of PV Value

PV stands for Pressure times Velocity. It’s the multiplication of your system’s operating pressure by how fast the seal face is spinning.

The math is straightforward. You take the pressure acting on the seal (measured in psi) and multiply it by the surface speed at the dynamic seal interface (measured in feet per minute). The result is expressed in psi-ft/min.

Engineers use PV as frictional power per unit area. When pressure goes up, friction increases. When speed increases, friction increases. Combine both, and you get an exponential effect on heat generation.

The industry has standardized around this parameter for decades. API 682, the American Petroleum Institute standard for pump shaft sealing systems, references PV limits extensively. So does ISO 21049:2004 for mechanical seals.

Why is PV Value Important for Seal Performance?

PV value determines the maximum operational stress your seal can handle before things go wrong.

The relationship is direct: higher PV means more heat at the seal faces. More heat leads to faster wear. Push it too far, and you’ll see thermal damage, cracking, and ultimately seal failure.

I prefer thinking about PV as a wear predictor. A seal running at 50,000 psi-ft/min will last significantly longer than the same seal running at 150,000 psi-ft/min, assuming all other conditions stay equal.

PV also guides your material selection decisions. Carbon faces paired with ceramic can handle around 150,000 psi-ft/min in warm water. But switch to tungsten carbide as the mating face, and you can push that limit to 500,000 psi-ft/min.

How Do You Calculate the PV Value?

What is the PV Calculation Formula for Rotary Seals?

Calculating PV for rotary applications takes five steps. Here’s how to do it:

Step 1: Measure the shaft diameter

Get the diameter where the seal rides on the shaft. Record it in inches. For example, let’s say you have a 4-inch shaft.

Step 2: Find the rotational speed

Check your equipment’s RPM. Most pumps display this on the nameplate. We’ll use 1,000 RPM for this example.

Step 3: Calculate surface velocity

Use this formula: V = (π × diameter × RPM) ÷ 12

With our 4-inch shaft at 1,000 RPM:

V = (3.14159 × 4 × 1,000) ÷ 12 = 1,047 feet per minute

Step 4: Determine system pressure

Find the pressure at the seal chamber in psi. Let’s say it’s 50 psi.

Step 5: Multiply pressure by velocity

PV = 50 psi × 1,047 fpm = 52,350 psi-ft/min

That’s a mild PV value. Most standard seals will handle this without breaking a sweat.

What is the PV Calculation Formula for Reciprocating Seals?

Reciprocating applications use a different formula because the motion isn’t continuous rotation.

The formula is: PV = 2 × Stroke Length (in feet) × Cycle Rate (cycles/min) × Pressure (psi)

The “2” accounts for both directions of travel in each cycle.

Let’s run through a quick example. You have a hydraulic cylinder with a 3-inch stroke, cycling 100 times per minute, operating at 500 psi.

First, convert the stroke to feet: 3 inches ÷ 12 = 0.25 feet

Then calculate: PV = 2 × 0.25 × 100 × 500 = 25,000 psi-ft/min

That’s well within the mild range for most sealing materials.

What are the Standard PV Limits for Mechanical Seals?

What Do Different PV Ranges Indicate?

The seal industry has established clear PV thresholds that tell you what to expect from your application.

| PV Range (psi-ft/min) | Classification | What to Expect |

|---|---|---|

| Below 30,000 | Mild | Standard catalog seals work great. Expect nominal wear and long service life. |

| 30,000 – 100,000 | Moderate | Most industrial applications fall here. Pay attention to material selection. |

| 100,000 | Transition Point | This is where things get interesting. You’re moving from normal wear to accelerated wear. |

| 100,000 – 200,000 | High | Careful material selection required. Consider enhanced cooling. |

| Above 200,000 | Severe | Call your seal engineer. Standard solutions won’t cut it. |

A PV below 30,000 psi-ft/min is where you want to be. Most off-the-shelf sealing solutions perform well at these levels with predictable service life.

Once you hit 100,000 psi-ft/min, you’re at what engineers call the transition point. The wear rate starts climbing noticeably. You should definitely have a conversation with your seal supplier if you’re operating in this range.

Above 200,000 psi-ft/min, you’re in the severe wear zone.

How Do Face Materials Affect PV Limits?

Your choice of face materials dramatically changes what PV your seal can handle.

| Material Combination | Typical PV Limit (psi-ft/min) | Best Applications |

|---|---|---|

| Carbon vs Ceramic | 150,000 – 205,000 | General industrial, water services |

| Carbon vs Tungsten Carbide | Up to 500,000 | High-performance pump applications |

| Carbon vs Silicon Carbide | 2.3× higher than Carbon/Alumina | Chemical processing, high-wear environments |

| Silicon Carbide vs Silicon Carbide | 33% higher than Carbon/Ceramic | Abrasive media, generates 50% less heat |

Running carbon against ceramic in 150°F water gives you about 150,000 psi-ft/min. Switch that same ceramic face for silicon carbide, and your PV capacity jumps by 2.3 times.

Silicon carbide running against itself offers something special: 33% higher PV capacity than carbon-ceramic pairs while generating half the heat. That’s why you’ll find SiC/SiC combinations in demanding refinery and chemical plant applications.

API 682, the industry’s go-to standard for pump shaft sealing, now favors reaction-bonded silicon carbide for refinery applications. The chemical industry prefers sintered silicon carbide for its superior corrosion resistance.

What Factors Affect the PV Limit of a Mechanical Seal?

How Does Lubrication Impact PV Performance?

Lubricating fluids can increase your seal’s PV limit by 50-60%.

The industry rule of thumb: multiply your non-lubricating PV limit by 1.5 to 1.6 when working with lubricating fluids like oils. A seal rated at 100,000 psi-ft/min in water might handle 150,000-160,000 psi-ft/min in light hydrocarbon oil.

How Does Temperature Influence PV Limits?

Higher operating temperatures reduce your PV limit. There’s no way around it.

As temperature climbs, seal materials lose some of their mechanical properties. Elastomers soften. Face materials become more susceptible to thermal shock. The whole system becomes more vulnerable to damage.

Wear rate increases with temperature too. The same PV that works fine at 100°F might cause rapid degradation at 300°F.

What Other Operating Factors Should You Consider?

PV isn’t the whole story. Several other factors affect how close you can safely run to the published limit:

- Shaft runout and eccentricity – A shaft that wobbles creates uneven loading on the seal faces. This concentrates wear in specific areas and can cause premature failure even at modest PV values.

- Extrusion gap clearance – The gap between the seal and its housing matters. Too large, and the elastomer can extrude under pressure. Too tight, and you create additional friction.

- Fluid viscosity at operating temperature – Thicker fluids provide better lubrication. Thin fluids at high temperatures offer less protection.

- Shaft surface finish – A rough shaft acts like sandpaper against the seal lip. Industry specs typically call for 10-20 microinch Ra finish for seal journals.

- Heat transfer capability – How well can your system dissipate the heat generated? Better heat transfer means you can operate closer to PV limits.

What are the Limitations of Using PV Value Alone?

Why Can’t You Select a Seal Based Only on PV?

Here’s something that caught me off guard when I first started working with seals: the same PV value can require completely different seals.

Think about it. You can get to 100,000 psi-ft/min in multiple ways:

- 100 psi at 1,000 fpm (low pressure, high speed)

- 500 psi at 200 fpm (high pressure, low speed)

- 250 psi at 400 fpm (medium pressure, medium speed)

Each scenario needs a different seal design. High-pressure, low-speed applications work best with spring-energized rotary seals. Low-pressure, high-speed applications perform better with cased lip seals.

The reason? High pressure and high speed damage seals through different mechanisms. Pressure causes extrusion and face distortion. Speed generates heat through friction. The seal that handles one well might fail at the other.

Why Do Manufacturer PV Ratings Vary?

You can’t directly compare PV ratings between different seal manufacturers. I wish someone had told me this earlier.

There’s no standardized industry test method for determining PV limits. One manufacturer might test using a 3-3/8″ unbalanced seal at 1,800 RPM in warm water for 100 hours. Another might use completely different parameters.

Some companies don’t even use seal tests. They base their PV ratings on bearing material tests and apply factors to estimate seal performance.

The 100-hour test duration creates another problem. Manufacturers extrapolate from 100 hours to predict 2-year (17,520 hour) service life. That’s a massive leap. The wear measurement they’re trying to capture is about 0.00071 inches – barely detectable with standard equipment.

When evaluating seals from different suppliers, focus on comparing their test conditions, not just the headline PV numbers. Ask what face materials, fluid types, and test durations they used.

Making PV Work for You

PV value gives you a starting point for mechanical seal selection. It’s the product of pressure and velocity at your seal face, measured in psi-ft/min, and it predicts how much heat and wear your seal will experience.

Keep these numbers in mind: below 30,000 psi-ft/min is mild territory where standard seals thrive. Above 200,000, you’re in severe conditions requiring specialized engineering. That 100,000 mark in between is your transition zone from normal to accelerated wear.

But don’t stop at PV. Consider your face materials (silicon carbide offers major advantages over ceramic), lubrication (oils can boost your limit by 50%), and temperature (heat is the real killer). Remember that same PV can come from different pressure-velocity combinations, each requiring different seal designs.