Have you ever struggled with a pump that refuses to prime?

A pump may fail to prime due to air leaks, clogged suction lines, or insufficient fluid in the system.

These issues can lead to reduced efficiency and potential damage to the pump. Understanding the causes of priming problems is crucial for maintaining optimal pump performance and preventing costly repairs.

How Self-Priming Pumps Work

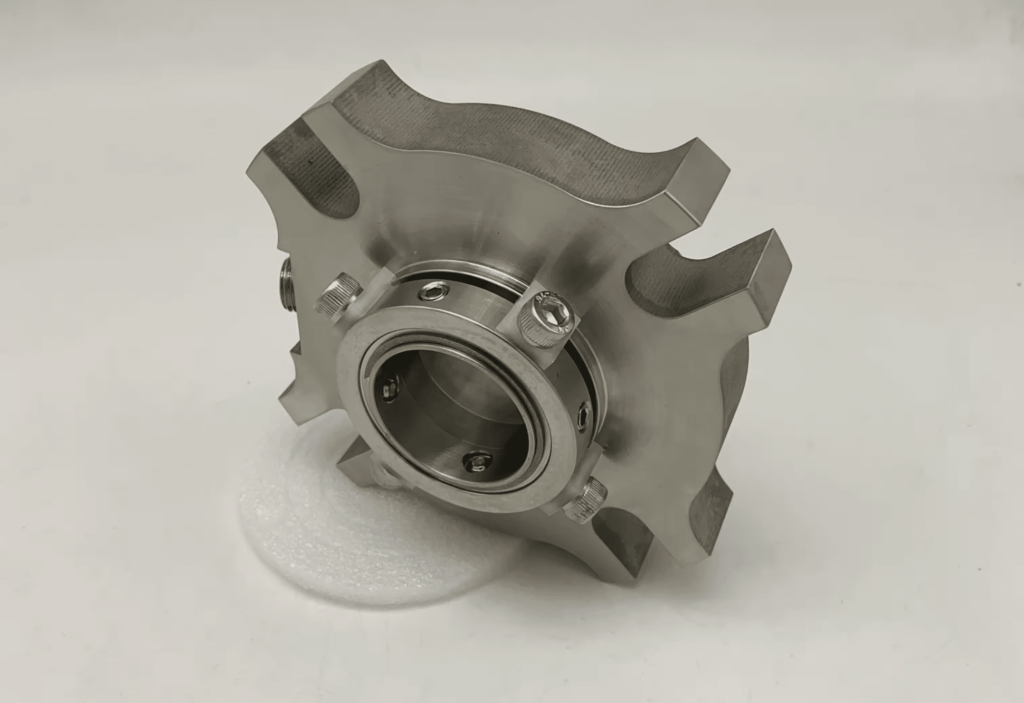

Self-priming pumps are designed to automatically remove air from the pump and suction line. These pumps contain a built-in liquid reservoir that retains fluid when the pump is off. Upon startup, the impeller creates a partial vacuum, drawing air from the suction line into the pump casing.

The air mixes with the liquid in the reservoir, forming a fluid-air mixture. This mixture is then discharged through a recirculation port back into the reservoir. As this process continues, more air is evacuated, and atmospheric pressure forces water up the suction line.

Once the pump is fully primed, it operates like a standard centrifugal pump. The impeller creates centrifugal force, moving water from the eye of the impeller to the discharge port. Self-priming pumps are particularly useful in applications where the water source is below the pump level.

Issues with initial priming liquid

Lack of proper initial fill

Self-priming pumps require an adequate amount of liquid in the pump casing to function properly. Without sufficient initial fill, the pump cannot create the necessary low-pressure area at the impeller eye to draw fluid up the suction line. This can occur due to improper priming procedures or failure to add enough liquid to the pump housing before startup.

Evaporation or leakage of prime

Even if a pump is initially primed correctly, the priming liquid can be lost over time due to evaporation or leaks. Air leaks in the suction line or pump casing can allow prime to escape, preventing the pump from maintaining the required vacuum. Additionally, extended periods of inactivity can lead to evaporation of the priming liquid, especially in hot environments.

Air leaks in the suction line

When air enters the suction line, it disrupts the pump’s ability to create the necessary negative pressure for priming. This can lead to reduced water flow, pump cavitation, and potential damage to pump components. Common locations for air leaks include the pump lid, strainer housing, and pipe connections.

Blockages and restrictions

Debris in the impeller

Debris accumulation in the impeller can significantly impair a pump’s priming ability. The impeller’s eye may become obstructed, reducing its hydraulic capability to create the necessary low-pressure area.

Plugged recirculation port

A plugged recirculation port prevents proper fluid circulation through the volute casing during the priming process. This obstruction hinders the creation of low pressure at the impeller’s eye, impeding the pump’s ability to draw liquid up the suction line.

Clogged suction strainers or foot valves

Suction strainers and foot valves can become clogged with debris, restricting water flow into the pump. This blockage can prevent the pump from achieving the required suction to prime effectively.

Pump becomes air-bound

Air Entrapment in Pump Casing

Air can become trapped in the pump casing when there is no proper air release mechanism. Self-priming pumps rely on the ability to evacuate air from the pump housing. Without an air release valve or port, air can accumulate, preventing the pump from creating the necessary low-pressure area for priming.

Closed Valves Impeding Water Flow

Closed valves in the system can obstruct water flow and contribute to air-binding. Valves on the suction side, such as foot valves or check valves, if closed or faulty, can prevent water from entering the pump. This creates a vacuum that traps air in the pump casing, making it impossible for the pump to prime.

Excessive Impeller Clearance

Impeller clearance that is too large can reduce the pump’s hydraulic capability. This excessive clearance diminishes the pump’s ability to create the low-pressure area needed at the eye of the impeller. Consequently, the pump struggles to draw water up the suction line, leading to air-binding issues.

Incorrect pump sizing and positioning

Excessive suction lift for pump size

Excessive suction lift occurs when the pump is positioned too high above the water source. This can prevent proper priming and reduce pump efficiency. Self-priming pumps typically have a maximum suction lift of 25-30 feet. Exceeding this limit strains the pump’s ability to create the necessary negative pressure for priming.

Pump too far from liquid source

Placing the pump too far from the liquid source increases friction losses in the suction line. This can lead to cavitation and reduced pump performance. The recommended maximum distance is usually 25-30 feet. Longer distances require larger diameter pipes to minimize friction losses and maintain adequate flow.

Undersized suction line diameter

An undersized suction line restricts water flow to the pump, potentially causing cavitation and priming issues. The suction line diameter should match or exceed the pump’s inlet size. Larger diameters reduce fluid velocity and friction losses, improving pump efficiency and reducing the risk of cavitation.

System design and operation issues

Discharge pressure issues

Excessive discharge pressure can prevent proper pump priming. High backpressure in the discharge line creates resistance that impedes the pump’s ability to evacuate air and draw in liquid. Installing a pressure gauge on the discharge side allows monitoring of pressure levels. A restrictor or relief valve may be needed to reduce discharge pressure during priming.

Suction-side problems

Insufficient net positive suction head available (NPSHA) and inadequate submergence are common causes of priming failures. Low NPSHA can lead to cavitation, while poor submergence may allow air entrainment through vortexing.

Pump rotation direction

Running a centrifugal pump backwards drastically reduces performance and can damage internal components. Performing a quick bump test to verify proper shaft rotation before coupling the motor is recommended when installing or servicing pumps. For three-phase motors, swapping any two power leads will reverse rotation if needed.

How to Fix Priming Problems

Restoring Initial Prime Liquid

- Ensure the pump casing contains sufficient liquid before starting.

- Fill the pump housing with water using a garden hose if needed.

- Check the water level in the pool or tank is high enough to reach the skimmer or suction inlet.

- Open the filter air relief valve while priming to release trapped air.

Repairing Suction Leaks

- Inspect all suction-side connections for air leaks, including pump lid, strainer housing, and pipe joints.

- Tighten loose fittings and replace damaged gaskets or o-rings.

- Check for cracks in the pump housing or strainer basket.

- Apply water to suction-side components while running to identify leaks.

Clearing Blockages

- Remove and clean the pump strainer basket.

- Inspect the impeller for debris and clear any obstructions.

- Flush the suction line to remove blockages.

- Ensure valves are fully open.

- Check for collapsed suction hoses or clogged foot valves on shallow well pumps.

Releasing Air-Bound Conditions

- Open the air release valve on the filter or pump to vent trapped air.

- Ensure the recirculation port is not plugged.

- For persistent air pockets, stop the pump and allow time for air to escape before restarting.

- Consider installing an automatic air release valve.

Correcting Pump and System Sizing

- Verify the pump is properly sized for the required flow rate and suction lift.

- Ensure piping is adequately sized to minimize friction losses.

- Check that the impeller diameter matches pump specifications.

- Address excessive clearance between the impeller and wear plate through proper reassembly or parts replacement.

In Conclusion

Pump priming issues often stem from air leaks, debris blockages, or improper setup. Regular maintenance and proper installation are crucial for optimal pump performance. Understanding these common problems enables quick troubleshooting and resolution.

For persistent priming issues, consult a professional pump technician. Take action today to ensure your pump operates efficiently and reliably.