Type 1

The Type 1 mechanical seal, also known as the Type E seal, is a single spring elastomer bellows shaft seal. It is one of the most common and widely used mechanical seals due to its versatility, reliability, and proven track record of exceptional performance in a variety of applications.

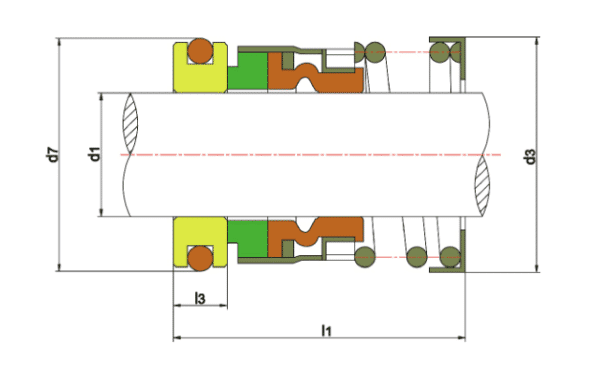

Mechancial seal drawing

Mechancial seal Chart

| Model | d1 (Inch) | d3 | d7 | l1 | l3 |

|---|---|---|---|---|---|

| Type 1–5/8″ | 15.875 | 27.76 | 31.75 | 43.81 | 10.29 |

| Type 1–3/4″ | 19.05 | 30.6 | 34.93 | 43.81 | 10.29 |

| Type 1–7/8″ | 22.225 | 35 | 38.1 | 45.43 | 10.29 |

| Type 1–1″ | 25.4 | 39 | 41.28 | 50.97 | 11.1 |

| Type 1–1 1/8″ | 28.575 | 42 | 44.45 | 52.58 | 11.1 |

| Type 1–1 1/4″ | 31.75 | 45 | 47.63 | 52.58 | 11.1 |

| Type 1–1 3/8″ | 34.925 | 49 | 50.8 | 52.58 | 11.1 |

| Type 1–1 1/2″ | 38.1 | 51 | 53.98 | 54.15 | 11.1 |

| Type 1–1 5/8″ | 41.275 | 58 | 60.33 | 54.15 | 12.7 |

| Type 1–1 3/4″ | 44.45 | 61 | 63.5 | 63.7 | 12.7 |

| Type 1–1 7/8″ | 47.625 | 63.8 | 66.68 | 63.7 | 12.7 |

| Type 1–2″ | 50.8 | 68 | 69.85 | 66.87 | 12.7 |

| Type 1–2 1/8″ | 53.9 | 71.42 | 76.2 | 74.8 | 14.27 |

| Type 1–2 1/4″ | 57.7 | 74.6 | 79.38 | 74.8 | 14.27 |

| Type 1–2 3/8″ | 60.3 | 77.7 | 82.55 | 77.97 | 14.27 |

| Type 1–2 1/2″ | 63.5 | 80.95 | 85.73 | 77.97 | 14.27 |

| Type 1–2 5/8″ | 66.6 | 85.73 | 85.73 | 85.95 | 15.9 |

| Type 1–2 3/4″ | 69.8 | 88.9 | 88.9 | 85.95 | 15.9 |

| Type 1–2 7/8″ | 73 | 92.8 | 95.25 | 89.1 | 15.9 |

| Type 1–3″ | 76.2 | 95.25 | 98.43 | 89.1 | 15.9 |

Key features

- Unbalanced design

- Single coil spring

- Elastomer bellows

- Bi-directional operation

- Set screw lock collars available

Materials of construction

- Rotary faces: Carbon graphite, silicon carbide, tungsten carbide

- Stationary seats: Ceramic, silicon carbide, tungsten carbide, stainless steel

- Bellows: Buna-N, Viton, EPDM, Aflas, Neoprene

- Metal parts: 304 stainless steel standard, 316 stainless steel optional

Operating limits

- Temperature: -40°F to 400°F/-40°C to 205°C (depending on materials used)

- Pressure: Type 1 up to 425 psi(g)/29 bar(g), Type 1B up to 1200 psi(g)/82 bar(g)

- Speed: Up to 5000 fpm or 25 m/s

Applications

The Type 1 mechanical seal is frequently used by the:

- Pulp and paper industry

- Petrochemical industry

- Food processing industry

- Wastewater treatment industry

- Chemical processing industry

- Power generation industry

It is commonly used in process pumps and other rotating equipment

Interchangeability

The Type 1 seal is interchangeable with seals from major manufacturers such as:

- John Crane Type 1

- AES Type 1

- Flowserve (Durametallic) Type 1

- Chesterton 155

- Garlock Type 1

FAQs

The main difference is that the Type 1 uses an elastomer bellows to provide axial movement, while the Type 2 uses multiple springs. The Type 1 therefore has a simpler, more clog-resistant design.

No, the Type 1 seal is designed to run with liquid lubrication between the seal faces. Dry running will lead to rapid overheating and seal failure.