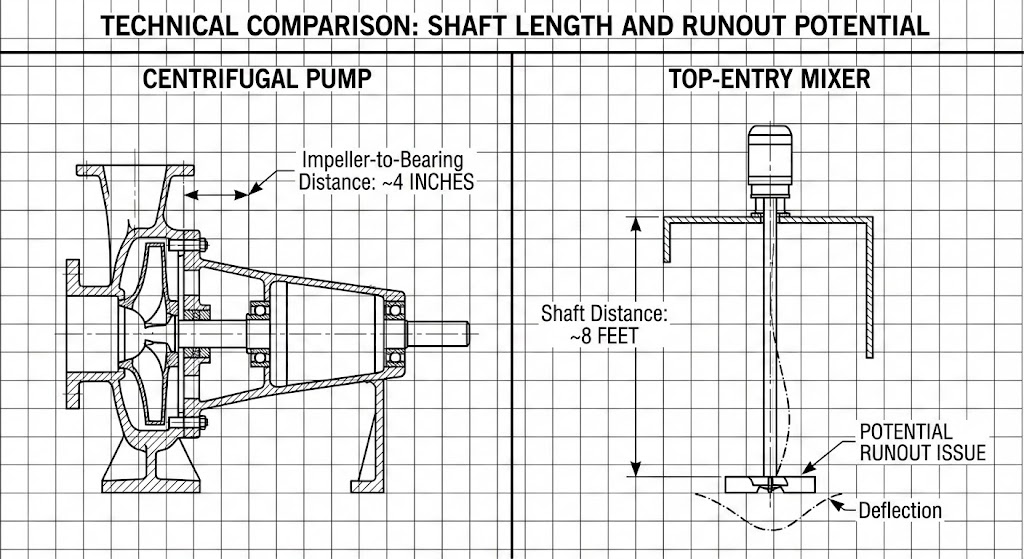

In a pump, the distance from impeller to radial bearing is measured in inches. In a top-entry mixer, that same distance is measured in feet. This fundamental geometric difference creates shaft runout 15 to 75 times greater than pumps – and explains why standard pump seals fail in agitator applications.

Selecting agitator mechanical seals requires a different approach than pump seal selection. The lower speeds (5-300 RPM), greater shaft deflection, and process heat soak demand specialized designs. This guide provides quantified selection criteria for operating pressure, temperature, shaft runout, and material compatibility.

Why Agitator Seals Differ from Pump Seals

The Fluid Sealing Association notes that “overhung pumps have shorter distances (typically measured in inches) from the impeller to the radial bearing when compared to a typical top entry mixer (typically measured in feet).” This long unsupported shaft creates a less stable platform with greater radial runout, perpendicular misalignment, and eccentricity.

API 682 specifies 0.002 inches Total Indicated Runout (TIR) for pump seals. Mixers operate with 0.03 to 0.150 inches TIR – a 15 to 75 times difference. Standard pump seal designs cannot accommodate this movement without rapid face wear and leakage.

Thermal management also differs fundamentally. In pumps, friction at the seal faces generates heat. In mixers operating at 5-300 RPM, barrier fluid temperatures rise primarily from process heat soak rather than seal friction. Cooling system design must address the reactor vessel temperature, not face-generated heat.

I’ve seen engineers specify pump seals for mixer applications expecting similar performance. The seals consistently fail within months.

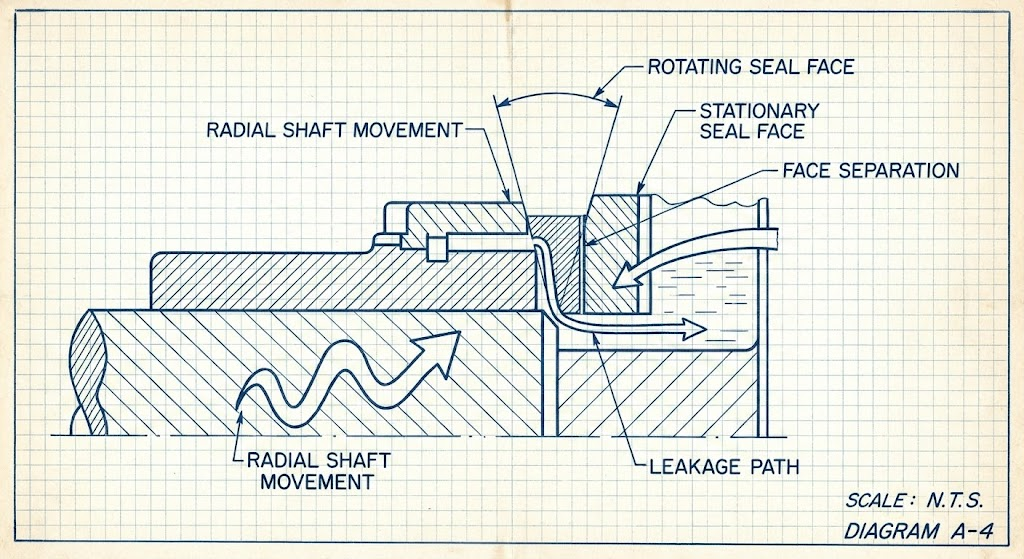

Shaft Runout Tolerance – The Critical Selection Factor

Shaft runout tolerance is the single most important specification for agitator seal selection. Excessive runout causes the rotating and stationary seal faces to lose full contact, creating a cascade of problems: increased leakage, accelerated wear, vibration and noise, intermittent dry-running with heat generation, and reduced seal life.

Different seal designs handle different runout levels:

| Seal Design | TIR Capability | Application |

|---|---|---|

| Standard agitator seal | 0.125 inch (3 mm) minimum | Most top-entry mixers |

| High-deflection designs | >0.250 inch | Side-entry agitators, severe misalignment |

| Standard pump seal | 0.002 inch | Incompatible with agitator applications |

At Domtar’s Nekoosa Mill, six side-entry agitators handling white liquor and abrasive slurries consumed over $82,000 annually in seal-related costs. Chronic leakage from shaft deflection caused premature bearing failure and unscheduled downtime. After implementing seals matched to actual runout conditions, annual costs dropped to approximately $8,000 – a $74,000 yearly savings that paid for the upgrade within the first year.

Before specifying any agitator seal, measure actual shaft TIR under operating conditions. I’ve seen too many seal specifications based on assumed runout values from equipment drawings that don’t reflect real-world deflection.

Pressure and Balance Ratio Selection

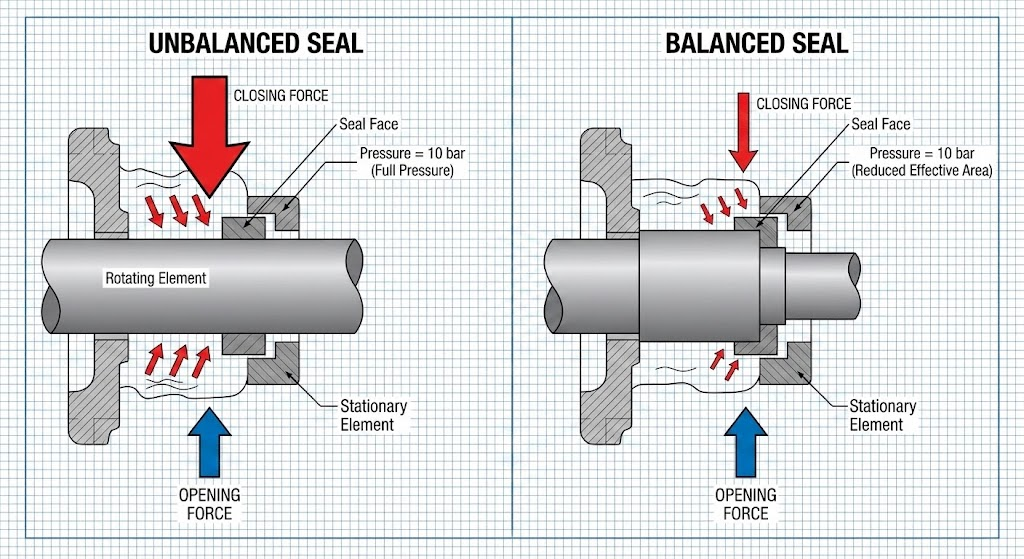

Operating pressure determines whether balanced or unbalanced seal designs are appropriate. The threshold is clear: unbalanced seals are typically limited to 10 bar (145 PSI). Above this pressure, balanced seals are required.

Balanced seals handle 250 PSI and above, with many designs operating at 400-600 PSI. The reduced face loading extends seal life and improves reliability in aggressive chemical service.

For reactor applications exceeding 10 bar, balanced seal designs are not optional. Unbalanced seals at higher pressures experience excessive face loading that accelerates wear and causes early failure. The balance ratio must be appropriate for the fluid – water service typically uses 0.75 balance ratio.

Seal Configuration Selection – Wet vs Dry

Choosing between wet (liquid-lubricated) and dry (gas-lubricated) seal configurations depends on contamination sensitivity and operating severity.

Wet seal applications:

- Process pressure exceeding 150 PSIG

- Temperature above 350F (177C)

- Applications where extended service life is priority

Lubricated seals typically last twice as long as dry seals under identical conditions. The liquid film provides superior face cooling and wear resistance.

Dry/gas seal applications:

- Pharmaceutical and food-grade processes requiring zero contamination

- Products that would be degraded by barrier fluid contact

- Lower-pressure applications within velocity limits

Dry-running contacting designs are typically limited to 2 m/s (400 fpm) surface velocity. Non-contacting spiral groove gas seals extend this range for specific applications.

Don’t default to dry seals for “cleanliness” without evaluating actual contamination requirements. Many food and chemical processes tolerate appropriate barrier fluids and benefit from the longer service life of wet seal configurations. Understanding the difference between single and double mechanical seals helps clarify configuration options.

Pusher vs Metal Bellows Design

Seal design selection – pusher or metal bellows – depends on operating conditions and chemical environment.

Pusher seal advantages:

- Better reverse pressure capability for dual pressurized applications

- Lower cost for standard applications

- Easier field repair in some configurations

Metal bellows advantages:

- High temperature capability to 425C (800F)

- No dynamic O-ring eliminates hangup potential and shaft damage

- Superior corrosion resistance with no elastomer in fluid path

- Better accommodation of shaft vibration and deflection

In an EagleBurgmann fermenter application for bioculture production, hard-hard face pairing with poor lubrication conditions challenged standard seal approaches. Metal bellows design provided reliable long-term sealing where pusher designs with dynamic elastomers failed.

For aggressive chemicals attacking elastomers, bellows designs eliminate the weakest link. I recommend bellows for high-temperature service above 350F, corrosive environments attacking elastomers, and applications with significant thermal cycling.

Material Selection for Chemical Service

Face and elastomer materials must match chemical exposure, temperature, and pressure conditions.

Seal face temperature limits:

| Material | Temperature Limit | Application Notes |

|---|---|---|

| Carbon | 350C (662F) | General service, runs in with hard mate |

| Silicon carbide | >500C (932F) | Aggressive chemicals, abrasives |

| Ceramic | <350F (177C) | Limited to lower temperatures |

Elastomer temperature ranges:

| Elastomer | Range | Chemical Resistance |

|---|---|---|

| Viton (FKM) | -20F to 400F | Broad chemical compatibility |

| Kalrez (FFKM) | To 615-620F | Maximum chemical resistance |

| EPDM | -40F to 300F | Steam, water, specific chemicals |

Material selection without knowing exact chemical composition is guesswork. As one practitioner notes: “It is impossible to specify a type of suitable seal material without knowing the specific chemical composition.” For aggressive vapors, vapor-purged double mechanical seals with dry nitrogen purge gas may be required.

Review mechanical seal materials in detail before finalizing specifications for chemical service.

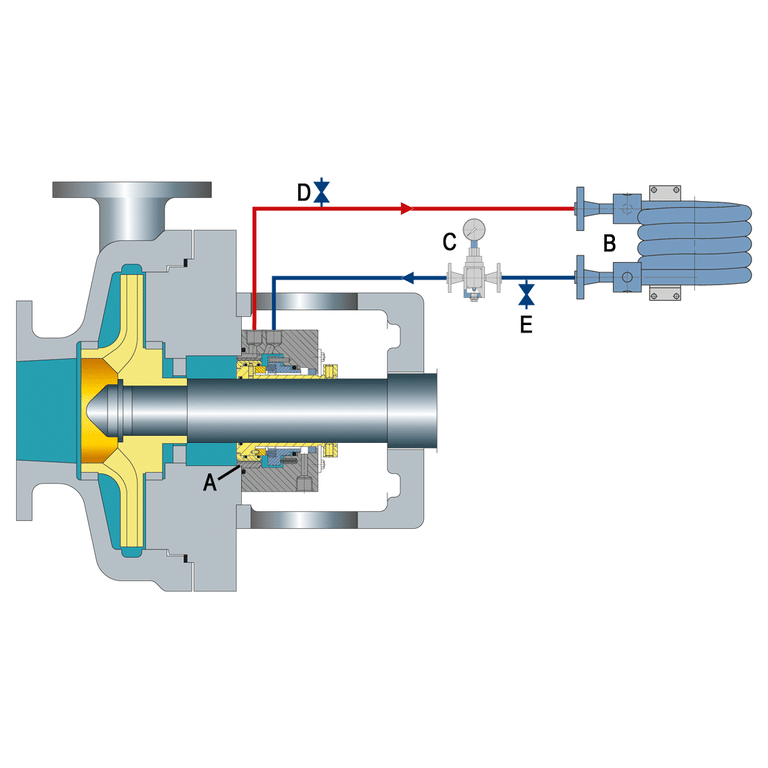

Support Systems and Flush Plans

Proper support system selection ensures seal reliability in reactor applications.

Barrier pressure requirements:

Dual seal configurations require barrier pressure higher than seal chamber pressure by at least 1.4 bar (20 PSI). This positive differential prevents process fluid from migrating between seal faces.

Nitrogen consumption monitoring for dry seals:

- Single seal: 1 standard cubic foot per hour per inch of shaft diameter

- Dual seal: 2 standard cubic feet per hour per inch of shaft diameter

Monitor consumption trends. Sudden increases indicate developing seal problems before visible leakage occurs.

Variable pressure reactor applications:

One reactor with double mechanical seals experienced outboard seal face failure with barrier fluid leakage varying inversely with reactor pressure – 150 drops at zero pressure, 1 drop per minute at maximum pressure. Variable reactor pressure created unstable differential pressure across seal faces. API Plan 53C, which automatically maintains constant 2 kg/cm2 pressure differential above actual vessel pressure, resolved the issue.

Standards Selection – Why API 682 Often Doesn’t Apply

Engineers often specify API 682 compliance for agitator seals because that’s the standard they know. The Fluid Sealing Association explicitly cautions against this: “Specifying API 682 for a mixer seal may be an unnecessary added expense and complication.”

API 682 was written for pumps complying with API 610 – machines with different dimensional, functional, and mechanical requirements than mixers. Invoking pump standards for mixers creates compliance problems and unnecessary cost.

Appropriate standards for agitator seals:

- DIN 28138/28154 – Agitator seal dimensions and requirements

- PIP RESM003 – Mixer mechanical seal specification

These standards address the unique requirements of mixer and reactor applications without the pump-centric requirements of API 682.

I’ve seen specifications requiring API 682 Category 1 compliance for mixers that couldn’t physically comply with API 610 dimensionally. The result was either rejected bids or creative interpretation of “equivalent compliance.” Starting with appropriate standards avoids these complications.

Conclusion

The $74,000 annual savings achieved at Domtar illustrates the value of proper selection methodology. Match seal capability to measured operating conditions, and agitator seals will deliver reliable service life instead of chronic maintenance problems.