What is API Plan 13

API Plan 13 is a standard piping arrangement for mechanical seals, as defined by the American Petroleum Institute (API). It is designed to provide a clean and cool environment for the mechanical seal by using a fluid reservoir and a heat exchanger.

How Does API Plan 13 Work

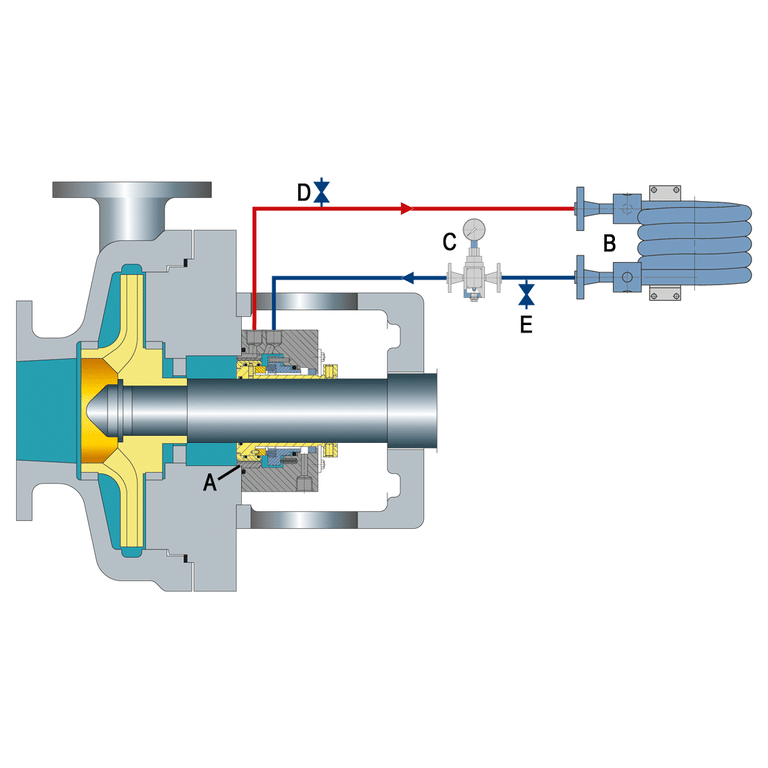

In API Plan 13, a fluid reservoir is connected to the seal chamber. The reservoir is typically mounted above the seal chamber to allow for gravity-assisted circulation. The fluid in the reservoir is usually the same as the process fluid, but it can also be a compatible barrier fluid.

The reservoir acts as a buffer, providing a constant supply of clean and cool fluid to the mechanical seal. As the fluid circulates through the seal chamber, it absorbs heat generated by the seal and any process fluid that may leak past the seal faces.

To keep the fluid in the reservoir cool, a heat exchanger is used. The heat exchanger is connected to the reservoir and an external cooling water source. As the fluid from the reservoir passes through the heat exchanger, it transfers heat to the cooling water, which is then discharged. The cooled fluid returns to the reservoir, ready to circulate through the seal chamber again.

Design of API Plan 13

- Fluid Reservoir: A tank that holds the flushing fluid, sized to ensure an adequate supply of clean fluid to the seal. It is typically made from materials like stainless steel or plastic, compatible with both the process fluid and the flushing fluid.

- Piping and Valves: The system that connects the reservoir to the seal chamber, including valves to control the flow of flushing fluid. The piping is designed to minimize pressure drops and ensure consistent fluid flow to the seal.

- Cooling System (Optional): Sometimes included to keep the flushing fluid at an acceptable temperature using a heat exchanger or cooling coil within the reservoir.

- Pressure Control: Utilizes a pressure regulator or orifice to control the flushing fluid’s pressure entering the seal chamber, ensuring it remains higher than the process fluid pressure to prevent contaminants.

- Filtration (Optional): Incorporates a filter to remove particles or contaminants, maintaining the cleanliness of the flushing fluid.

Advantages of API Plan 13

- Simple Design: API Plan 13 has a simple design that is easy to install and maintain.

- Cost-effective: It is a cost-effective solution for providing seal flush, as it does not require additional piping or equipment.

- Suitable for Clean Fluids: API Plan 13 works well with clean, non-abrasive fluids that are compatible with the seal materials.

Disadvantages of API Plan 13

- Limited to Clean Fluids: API Plan 13 is not suitable for fluids containing solids, abrasive particles, or fluids that can clog the flow control orifice.

- Dependent on Pump Operation: The seal flush is dependent on the pump’s operation, so if the pump stops, the seal flush also stops.

- Pressure Limitations: The seal chamber pressure is limited by the pump’s discharge pressure, which may not be suitable for all seal designs or applications.

Applications

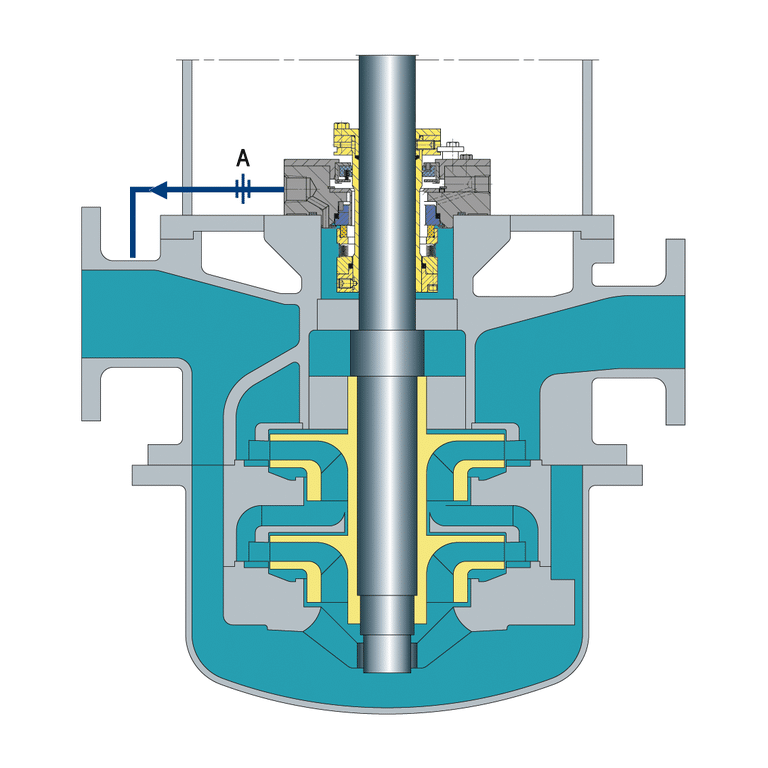

- Pumps

- Compressors

- Agitators and Mixers

- Reactors

- Heat Exchangers

- Refineries

- Petrochemical Plants