Should you specify API 682 because your pump came from an American manufacturer? Or DIN EN 12756 because the equipment has a European pedigree? Across the industry, I see engineers making this decision based on equipment origin rather than what actually matters: application risk.

Both standards have legitimate purposes, but they were designed for different operating envelopes. API 682 emerged from refinery requirements, written by end users who wanted robust seals for critical hydrocarbon service. DIN EN 12756 evolved from European industrial practice, covering a broader range of general applications. The question isn’t which is “better”—it’s which fits your specific situation.

Understanding API 682 and DIN EN 12756 Standards

API 682 is the American Petroleum Institute’s mechanical seal standard, developed by approximately 400 member companies primarily serving the petroleum and chemical industries. The standard requires seals to operate continuously for 25,000 hours without replacement—a rigorous benchmark that drives both design requirements and cost.

DIN EN 12756 (formerly DIN 24960) is the European standard that defines principal dimensions and performance requirements for mechanical seals in general industrial applications. It covers a wider range of seal configurations and places less emphasis on qualification testing than its American counterpart.

The key distinction isn’t geographic. API 682 assumes your application involves hazardous fluids, critical service, and the consequences of seal failure justify premium investment. DIN EN 12756 assumes a broader industrial context where seal requirements vary by application.

Key Differences Between API and DIN Seals

Design Philosophy and Testing

API 682 takes a prescriptive approach. The standard specifies seal categories (1, 2, and 3) based on operating conditions, with Category 1 covering -40F to 500F and up to 300 psi, Category 2 extending to 750F and 600 psi. Each category includes mandatory qualification testing that can require up to 200 hours per seal type.

DIN EN 12756 is more flexible in approach. It defines dimensional standards and material specifications but allows manufacturers greater latitude in design execution. This flexibility reduces cost but shifts more responsibility to the user for ensuring seal suitability.

Dimensional and Performance Specifications

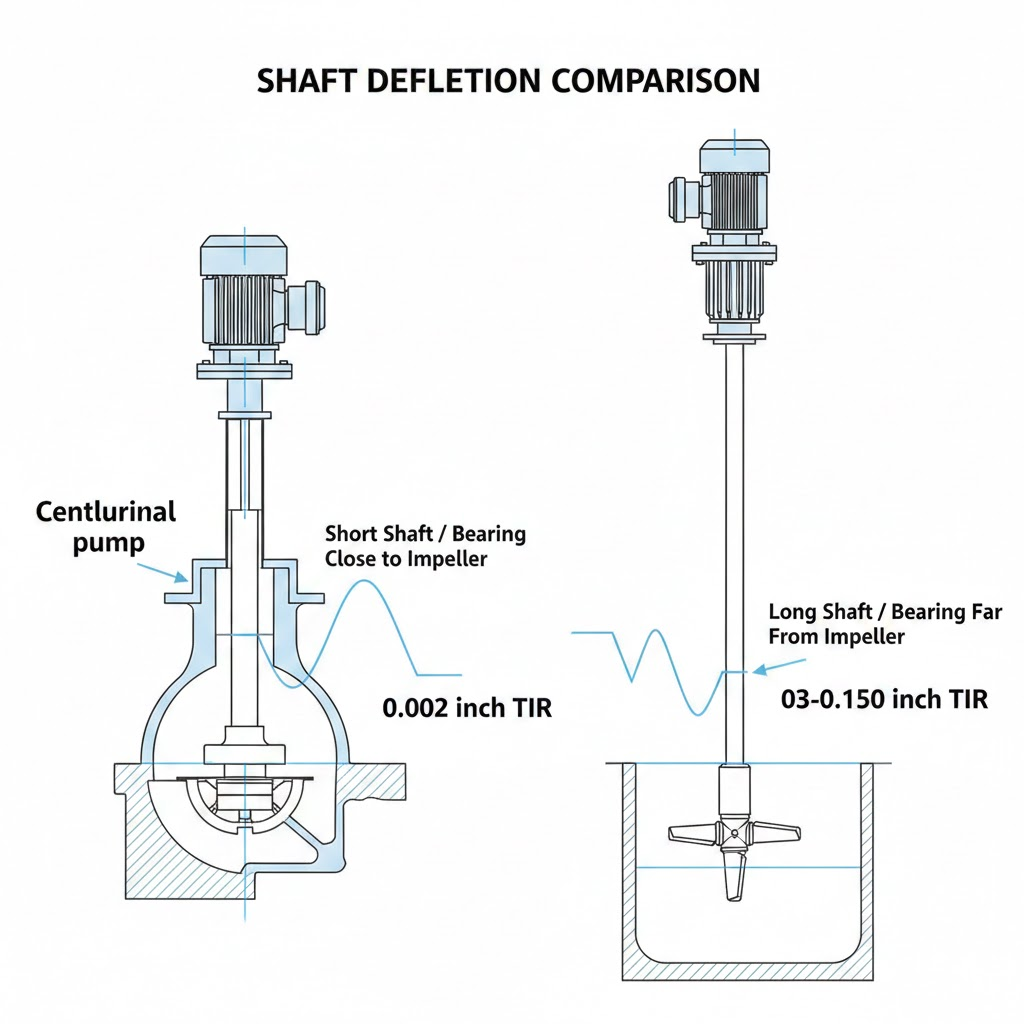

The most significant technical difference involves operating assumptions. API 682 assumes pump shaft deflection of 0.002 inch TIR (Total Indicator Runout) or less. This assumption works perfectly for centrifugal pumps but creates problems elsewhere.

Mixer and agitator applications, for instance, operate with shaft deflection ranging from 0.03 to 0.150 inch TIR—15 to 75 times higher than API 682’s design basis. Mixers also run at 5-300 rpm versus typical pump speeds. When engineers specify API 682 seals for mixer applications, they’re paying premium prices for design margins their equipment will never use.

European mixer OEMs have long specified DIN 28138/28154 for exactly this reason. The DIN approach matches seal design to actual operating conditions rather than worst-case refinery assumptions.

How to Select the Right Standard

When comparing options, the key factors aren’t where your equipment was manufactured or which standard your predecessor specified. They’re application severity and consequence of failure.

When API 682 Is the Right Choice

API 682 makes sense when:

- Process fluid is hazardous, toxic, or environmentally regulated

- Seal failure creates significant safety or environmental risk

- Operating conditions approach the edges of seal capability (high pressure, high temperature, aggressive chemistry)

- Downtime costs justify premium seal investment

- Your facility operates under API 610 pump requirements

The 4th Edition of API 682 introduced hazard-based selection using UN Globally Harmonized System classifications. This risk-based methodology acknowledges that even within refineries, not every seal application demands the same level of protection.

A Mumbai refinery audit of 600 seals implemented exactly this approach: critical equipment received three-month inspection intervals, semicritical equipment six months, and noncritical applications as-needed maintenance. They achieved 0.97 availability on critical equipment by matching investment to actual risk—not by applying maximum specification everywhere.

When DIN EN 12756 Makes More Sense

DIN EN 12756 is often the better choice when:

- Process fluid is water, mild chemicals, or non-hazardous

- Application involves mixers, agitators, or equipment with higher shaft deflection

- Operating conditions fall comfortably within standard seal capabilities

- Cost optimization is a priority without compromising reliability

- Equipment design already accommodates DIN dimensional standards

The hidden cost most buyers miss is over-specification. Specifying API 682 for a cooling water pump doesn’t make the seal last longer—it just increases purchase price and potentially complicates replacement sourcing.

Common Selection Mistakes

The most expensive mistake isn’t choosing the wrong standard—it’s assuming standard compliance alone ensures reliability.

A charge pump failure analysis revealed this clearly. After repeated seal failures, the facility upgraded to a higher-specification seal from a premium vendor. The result? Reliability got worse, not better. Weibull analysis showed characteristic seal life dropped from 3,859 hours to 2,321 hours after the “upgrade.”

Root cause wasn’t seal quality. Inadequate cooling capacity and poor seal face orientation were causing failures regardless of which standard the seal met. The facility had invested in a better seal without fixing the actual problem.

API 682 itself acknowledges this reality. The standard explicitly states it is “not a general purpose standard for mechanical seals.” It intentionally excludes large seals, high-pressure applications, mixer and rotary pump seals, outside-mounted configurations, and elastomeric bellows designs. These exclusions weren’t oversights—they reflect the task force’s decision to focus on refinery pump applications rather than attempt universal coverage.

When upgrading existing equipment, dimensional constraints add another layer of complexity. API 682 seals often won’t fit into existing ASME B73 pump seal chambers without housing modifications. This was intentional in the original standard design but frustrates users who assume API and DIN seals are directly interchangeable.

Making the Right Decision

Standard selection should follow application risk assessment, not regional preference or equipment origin. Start with these questions:

- What are the consequences of seal failure? (Safety, environmental, cost)

- Do your operating conditions require API 682’s design margins?

- Does your equipment actually accommodate API 682 dimensional requirements?

- Does the cost premium align with the risk reduction you’re achieving?

For critical hydrocarbon service in refinery environments, API 682 delivers the reliability its designers intended. For general industrial applications—especially those involving mixers, water systems, or non-hazardous fluids—DIN EN 12756 often provides adequate reliability at appropriate cost.