Mechanical seals shouldn’t be reused in most cases—it’s like trying to reuse a gasket from your car engine after you’ve already taken it apart. While it might look fine on the outside, the internal components have likely experienced wear that makes them unreliable for another round of service.

Why Reusing Mechanical Seals Is Usually a Bad Idea

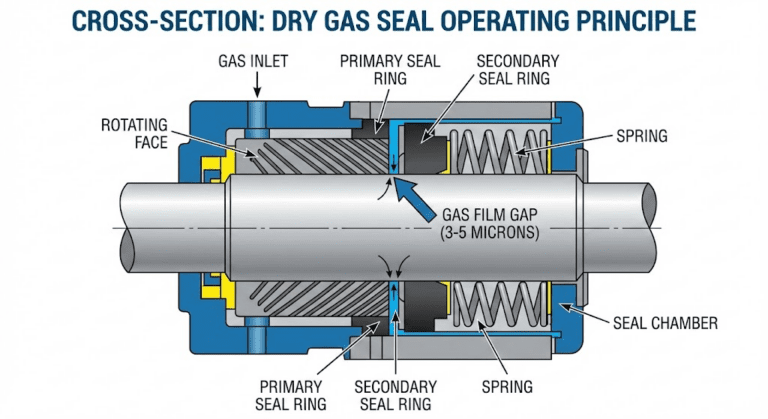

The seal faces—the most critical parts of any mechanical seal—develop microscopic wear patterns during their first use. These tiny grooves and scratches are invisible to the naked eye but compromise the seal’s ability to prevent leaks.

Think of it like a used brake pad. Even if it still has some material left, you wouldn’t put it on a different car because it’s already worn to match the specific rotor it was paired with.

The elastomers (rubber parts) inside the seal also take a permanent set once compressed. They won’t spring back to their original shape, which means they can’t create the proper sealing pressure they were designed for.

When You Might Consider Reusing a Seal

There are three specific situations where reuse could make sense, though they’re rare.

First, if you’re removing a nearly new seal (less than a few weeks old) for routine maintenance and plan to reinstall it in the exact same position. The wear patterns haven’t fully developed yet, and you’re not changing the operating conditions.

Second, during emergency repairs when you have no other option. If your plant is shut down and you’re waiting for a replacement seal, reinstalling the old one might buy you enough time to keep operations running—just know it’s a temporary fix.

Third, for non-critical applications where a small leak wouldn’t cause safety issues or significant product loss. A cooling water pump in a redundant system might be a candidate, but never try this with hazardous chemicals or high-pressure systems.

How to Evaluate a Seal for Potential Reuse

If you’re determined to try reusing a seal, here’s how to inspect it properly:

- Check the seal faces: Look for any visible scratches, chips, or heat damage (usually appears as discoloration). If you see any damage, don’t reuse it.

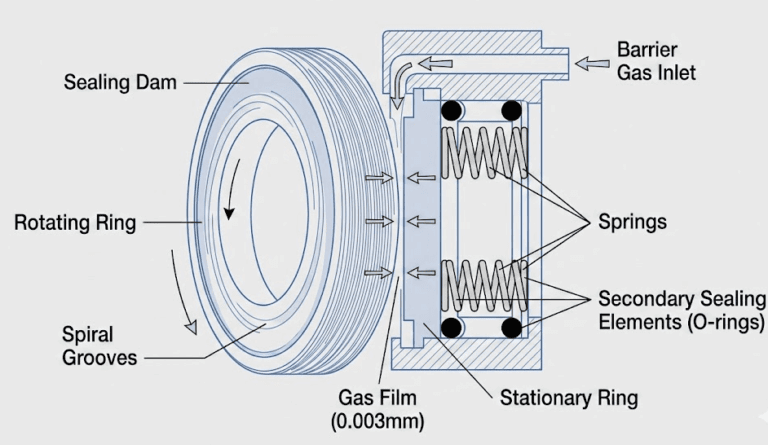

- Test the springs: The springs should compress smoothly and return to their original length. Corroded or stretched springs mean the seal is done.

- Examine all rubber components: Press on the O-rings and gaskets—they should bounce back immediately. If they stay indented or feel hard and brittle, the seal won’t work properly.

- Measure the seal faces: Use a micrometer to check if the faces are still within manufacturer specifications. Even 0.001 inches of wear can cause leaks.

- Document everything: Take photos and measurements before deciding to reuse. This protects you if something goes wrong later.

Making the Smart Decision

The question isn’t really whether you can reuse a mechanical seal—it’s whether you should. In almost every case, the risk isn’t worth the savings.

For critical equipment, always use new seals. For everything else, weigh the potential consequences of failure against the cost savings. If a leak would shut down production, contaminate product, or create safety hazards, install a new seal.

Remember that mechanical seals are precision devices operating under demanding conditions. They’re not designed for multiple installations, and treating them as reusable parts is asking for trouble.

FAQs

How long do mechanical seals typically last?

Most mechanical seals last between 2-5 years under normal operating conditions. Factors like temperature, pressure, and the type of fluid being sealed significantly affect lifespan. Clean, cool water applications might see 5+ years, while hot, abrasive slurries might only get 6-12 months.

Can mechanical seals be repaired instead of replaced?

Yes, professional seal repair services can rebuild many mechanical seals by replacing worn faces, springs, and elastomers while keeping the metal housing. This typically costs 50-70% of a new seal price and provides like-new performance when done correctly.

What causes mechanical seals to fail prematurely?

The most common causes are improper installation (about 40% of failures), running dry, excessive vibration, and chemical incompatibility with the sealed fluid. Poor water quality, particularly hard water that causes mineral buildup, is another frequent culprit in water pump applications.

How do I know when a mechanical seal needs replacement?

Watch for visible leaking, unusual noises from the seal area, or increased temperature near the seal housing. A sudden increase in bearing temperature often indicates seal problems. Any visible leak means immediate replacement is needed—seals don’t “heal” themselves.