The reusability of a mechanical seal depends on several factors, including the type of seal, its condition, application requirements, and manufacturer recommendations. While it may be possible to reuse a mechanical seal in some cases, doing so comes with inherent risks that must be carefully evaluated.

Factors Determining Reusability

Type of Seal

Different types of mechanical seals have varying reusability potential. Some seals, such as single-spring designs, may be more suitable for reuse compared to more complex seals like double or tandem arrangements.

Condition of the Seal

The overall condition of the mechanical seal is a crucial factor in determining its reusability. Seals that show signs of wear, damage, or contamination should not be reused as they may no longer provide adequate sealing performance. A thorough inspection is necessary to assess the seal’s condition before considering reuse.

Application

Seals exposed to harsh environments, abrasive media, or extreme temperatures may not be suitable for reuse due to accelerated wear and degradation. The compatibility of the seal materials with the process fluids must also be considered.

Manufacturer Recommendations

Mechanical seal manufacturers often provide guidelines regarding the reusability of their products. It is essential to consult the manufacturer’s recommendations, as they have specific knowledge about the seal’s design, materials, and performance limits.

Risks and Consequences of Reusing a Mechanical Seal

- Leakage: Reusing a worn or damaged mechanical seal increases the risk of fluid leakage, which can result in product loss, environmental contamination, and non-compliance with regulations.

- Equipment Damage: A reused seal that fails to provide proper sealing can allow process fluids to enter and damage bearings, shafts, and other critical components of the equipment.

- Increased Downtime: Seal failure due to reuse often leads to unscheduled downtime, disrupting production and incurring additional maintenance costs.

- Safety Hazards: Leakage caused by a reused seal can create safety hazards, such as slippery surfaces, exposure to hazardous fluids, or even fire and explosion risks in some cases.

- Seal Failure: Reusing a mechanical seal increases the likelihood of premature seal failure, as the seal may have already experienced wear and tear from its previous service life.

Procedure for Reusing a Mechanical Seal

If, after careful consideration of the risks and manufacturer recommendations, reusing a mechanical seal is deemed appropriate, follow these steps:

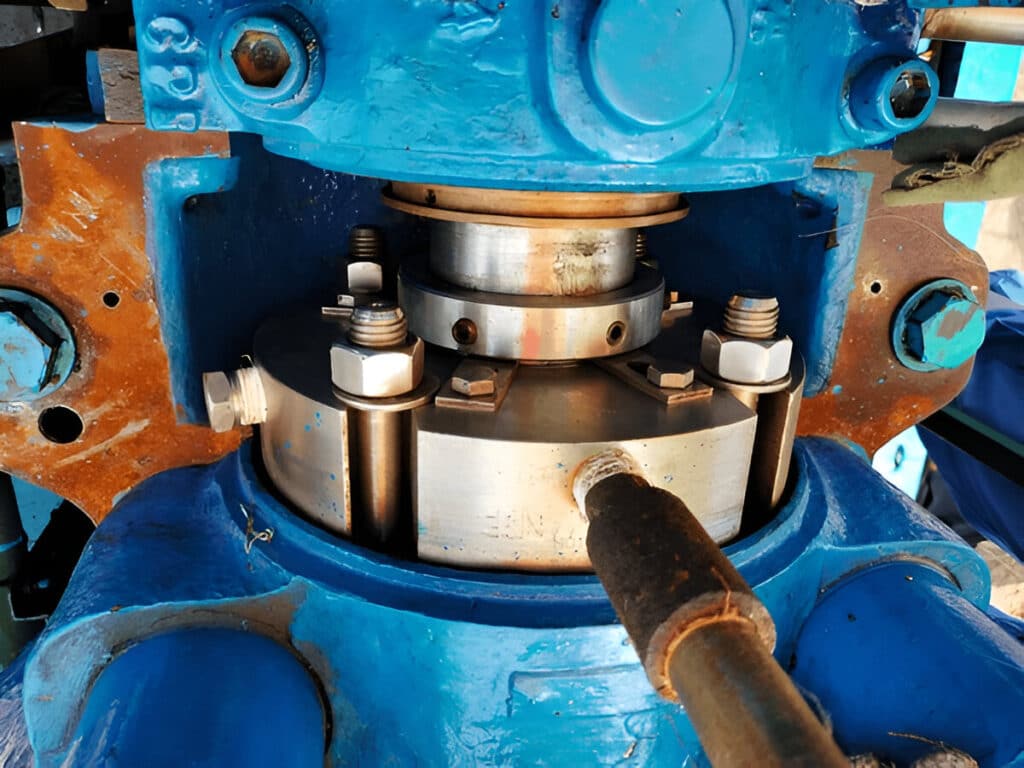

Step 1: Inspection

Thoroughly inspect the seal for any signs of damage, wear, or contamination. Check the sealing faces for scratches, pitting, or unevenness. Examine the elastomeric components for hardening, cracking, or swelling. If any defects are found, the seal should not be reused.

Step 2: Cleaning

If the seal passes inspection, clean it thoroughly to remove any dirt, debris, or process fluids. Use appropriate cleaning agents and methods as recommended by the seal manufacturer. Be cautious not to damage the sealing faces or elastomeric components during cleaning.

Step 3: Storage

After cleaning, store the seal in a clean, dry environment away from direct sunlight and extreme temperatures. Protect the sealing faces from damage by using proper storage containers or wrapping materials. Label the seal with relevant information, such as the date of removal and the equipment it was used in.

Step 4: Reassembly

When reassembling the mechanical seal, follow the manufacturer’s instructions carefully. Ensure that all components are correctly aligned and properly lubricated. Use new gaskets, O-rings, or other secondary sealing elements as recommended by the manufacturer.

Step 5: Testing

After reassembly, test the mechanical seal under normal operating conditions to verify its performance. Monitor for any signs of leakage, excessive heat generation, or unusual noise. If any issues arise, shut down the equipment immediately and replace the seal with a new one.