What Are Cartridge Mechanical Seals

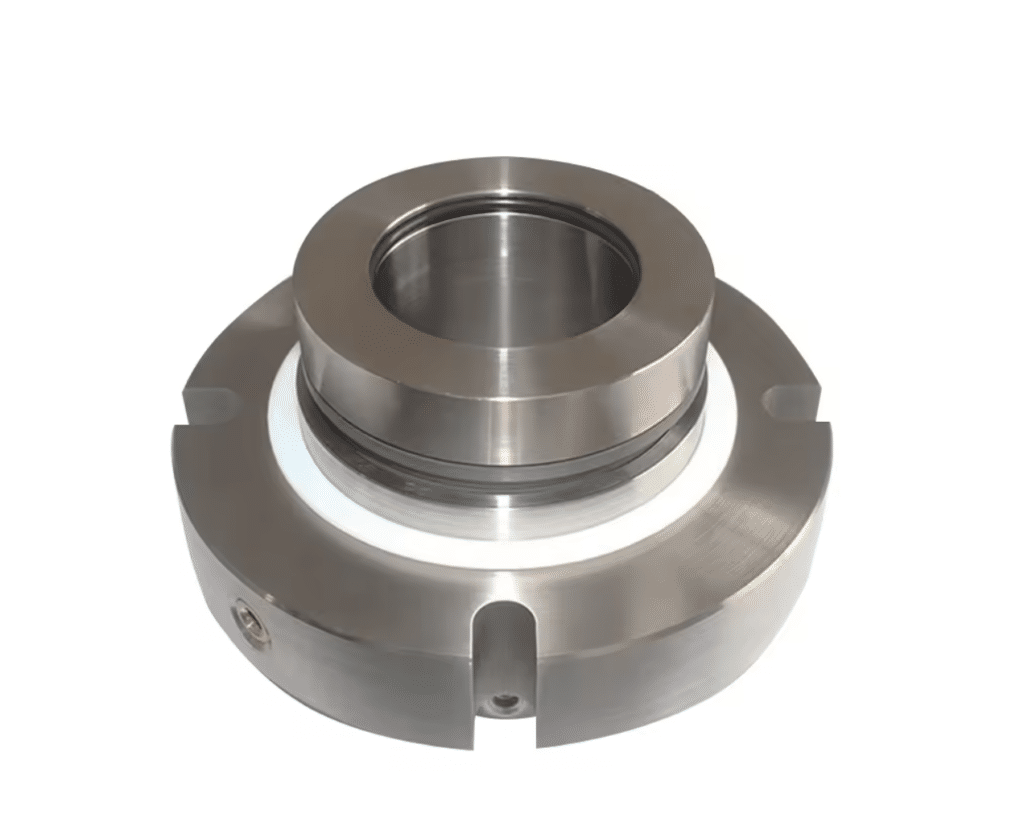

Cartridge mechanical seals are pre-assembled, self-contained units that combine the seal and gland plate into a single component. These seals are designed for easy installation and removal, as they do not require significant disassembly of the pump or equipment. Cartridge seals typically consist of a seal head, seal seat, secondary seals, and a gland plate, all pre-assembled and preset at the factory to ensure optimal performance.

Advantages of Cartridge Mechanical Seals

- Easy installation: Cartridge seals are pre-assembled and pre-set, minimizing the chances of installation errors and reducing downtime.

- Reliability: The factory assembly and testing of cartridge seals ensure optimal performance and minimize the risk of premature failure.

- Reduced maintenance: Cartridge seals require less frequent maintenance compared to component seals, as they are designed to be a complete replacement unit.

- Versatility: Cartridge seals can be used in a wide range of applications and are available in various materials to suit different process conditions.

- Improved safety: The pre-assembled design of cartridge seals reduces the risk of accidents during installation and maintenance.

Disadvantages of Cartridge Mechanical Seals

- Higher initial cost: Cartridge seals are generally more expensive than component seals due to their pre-assembled design.

- Limited customization: Cartridge seals are designed for specific equipment and may not be easily customizable for unique applications.

- Storage requirements: Cartridge seals require careful storage to prevent damage to the pre-assembled components.

When to Use Cartridge Mechanical Seals

- Minimal downtime is required for seal replacement.

- Maintenance staff has limited expertise in seal installation.

- The process fluid is hazardous or requires containment.

- The equipment operates in harsh conditions, such as high temperatures or pressures.

- Standardization of seals across multiple pumps or equipment is desired.

What Are Split Mechanical Seals

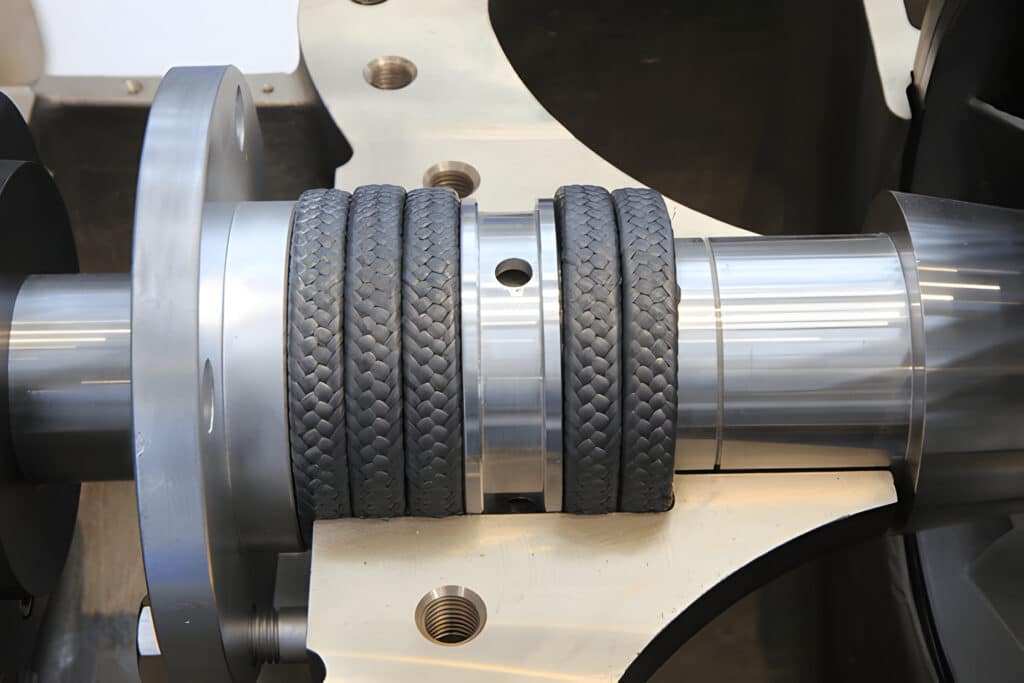

Split mechanical seals consist of individual parts that are assembled on-site during installation. These seals are designed to be installed without completely disassembling the pump or equipment, making them suitable for applications where cartridge seals may not fit or where frequent seal replacement is not required.

Split seals typically consist of a seal head, seal seat, secondary seals, and a gland plate, which are assembled and adjusted during installation to ensure proper alignment and sealing. This design allows for greater flexibility in seal configuration and customization, as the individual components can be selected based on the specific application requirements.

Advantages of Split Mechanical Seals

- Cost-effective: Split seals generally have a lower upfront cost compared to cartridge seals, as they do not include the additional components and assembly costs associated with pre-assembled units.

- Customizable: Split seals can be easily customized to suit specific equipment or process requirements.

- Retrofit capability: Split seals can be installed on existing equipment without major modifications, making them suitable for retrofit applications.

- Repair and maintenance: Individual components of split seals can be replaced or repaired without replacing the entire seal assembly, reducing maintenance costs.

Disadvantages of Split Mechanical Seals

- Installation complexity: Split seals require on-site assembly and careful installation, which can be time-consuming and prone to errors if not performed by skilled personnel.

- Alignment issues: Proper alignment of split seal components is critical for optimal performance, and misalignment can lead to premature seal failure.

- Increased leakage risk: Split seals have more potential leak paths compared to cartridge seals due to the multiple components and on-site assembly.

- Limited application range: Split seals may not be suitable for high-pressure, high-temperature, or highly corrosive applications.

When to Use Split Mechanical Seals

- Equipment cannot be easily disassembled for seal replacement.

- The shaft size or configuration makes cartridge seals impractical.

- The process conditions are not extreme, such as moderate temperatures and pressures.

- Customization of the seal is required to meet specific equipment or process needs.

- Budget constraints make cartridge seals less feasible.