Labyrinth seals keep contaminants out and prevent fluid or gas leakage in rotating equipment. When they fail, you lose efficiency, watch leaks multiply, and face unexpected downtime. Understanding what causes these failures gives you the power to spot problems early and prevent expensive damage to your equipment.

1. Contamination and Debris

Foreign particles are the leading cause of labyrinth seal failure. Dirt, dust, sand, metal shavings, and water work their way into the seal’s passages and destroy the sealing effectiveness.

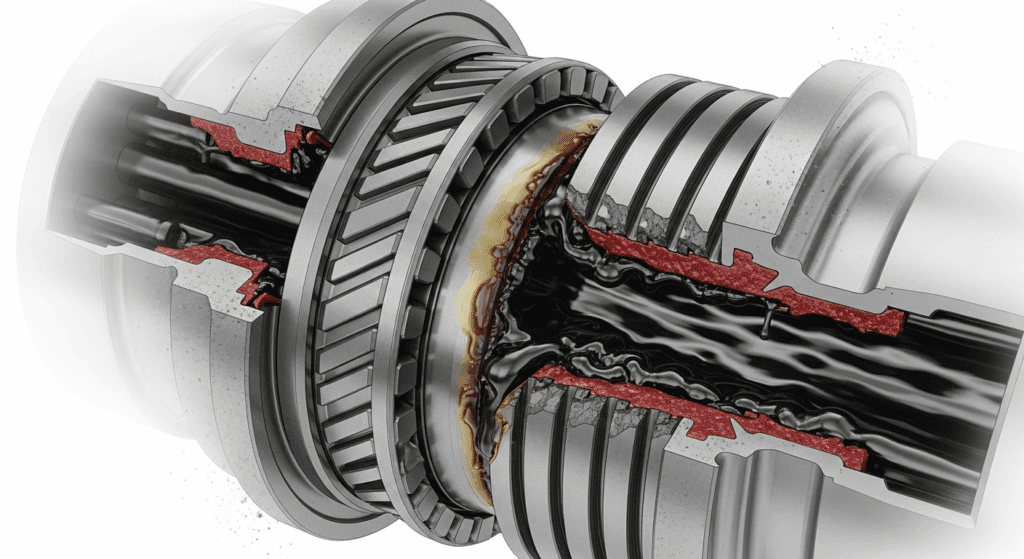

The labyrinth’s design normally prevents contamination through a maze-like pathway that uses centrifugal force to push particles back outward. But when debris bypasses this protection (through poor installation, damaged seals, or extreme operating conditions), particles get stuck in the passages and block the flow. Once the passages clog, the seal loses its ability to control leakage.

Water contamination is particularly damaging. As little as 0.05 percent water in bearing grease will substantially shorten seal life and accelerate failure. Water causes corrosion, lubricant breakdown, and creates a pathway for more contamination to enter.

Operators can reduce contamination by maintaining clean work environments during maintenance, using filtered air during greasing procedures, and inspecting seals regularly for signs of debris accumulation.

2. Thermal Expansion and Clearance Closure

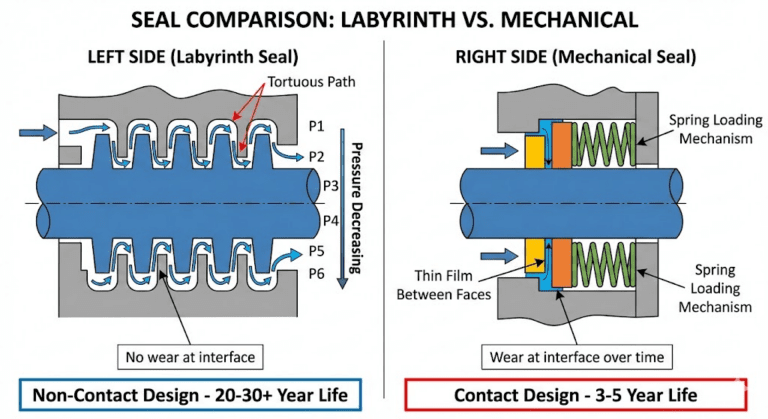

Temperature changes directly affect seal clearances. Labyrinth seals work by maintaining precise gaps between rotating and stationary components (typically 0.010 to 0.020 inches per inch of shaft diameter). When temperature rises, both the shaft and seal housing expand, but at different rates.

Thermal expansion can close these clearances unpredictably. In extreme cases, the seal components contact each other. That shouldn’t happen with a non-contact seal design. But when it does, friction spikes, material wears away, and the seal deteriorates fast.

The problem gets worse in equipment with uneven temperature distribution. If one side of the seal runs hotter than the other, clearances become nonuniform along the seal’s path, creating weak spots where failure is more likely.

Engineers must account for thermal expansion when designing clearances, but operators need to monitor temperature trends. Rising temperatures combined with increasing leakage indicates thermal stress on your seals.

3. Vibration and Misalignment

Excessive vibration forces the shaft to move in ways labyrinth seals can’t handle. When the shaft vibrates or drifts out of alignment, clearances shift rapidly and seal teeth start hitting the housing.

Even slight shaft imbalance produces vibrations you might not notice, but they damage seals over time. Worn impellers cause hydraulic imbalance and increase vibration, which leads directly to seal contact and wear.

Labyrinth seals create their own destabilizing forces on the shaft (forces that depend on pressure drop, swirl velocity, and rotational speed). At certain operating conditions, these seal-generated forces amplify existing vibration problems. The result is a feedback loop that accelerates seal deterioration.

Operators should monitor vibration levels and address imbalance problems promptly. If your equipment has been showing signs of vibration (unusual noise, noticeable shaking), your labyrinth seals are already taking damage.

4. Wear from High-Speed Operation

Running equipment at high speeds subjects labyrinth seals to intense centrifugal forces. These forces pull outward on seal components, causing deflection and changing clearances during operation. At speeds exceeding 10,000 rpm, these effects become pronounced.

When seal fins contact the housing (a problem called “rub”), the wear mechanism changes based on speed. At lower speeds, oxidation and adhesive wear develop slowly. As speed increases, delamination kicks in (the seal material separates in layers). At the highest speeds, metal-to-metal wear takes over and destroys components in minutes.

High-speed equipment also experiences degradation from corrosion during idle periods. When equipment sits inactive, moisture and oxygen attack the seal material, sometimes causing more damage than mechanical wear during operation. This is especially problematic for equipment in coastal or humid environments.

5. Installation Mistakes

Poor installation causes a huge percentage of premature seal failures. Steel tools damage the precisely machined teeth. Even tiny deformations or chips change clearances and destroy sealing effectiveness.

Wrong installation technique also misaligns seal components. Install rings without proper support or use too much force, and the seal geometry shifts out of spec immediately.

Incorrect clearance specifications create problems too. Clearance too tight? Thermal expansion closes the gap completely. Clearance too loose? Leakage skyrockets beyond design limits. Both lead to failure.

Operators should always follow manufacturer installation procedures exactly. Use soft-faced hammers, proper installation tools, and never force components into place. If you’re unsure about clearance specifications for your equipment, verify them with the manufacturer before assembly.

6. Inadequate Lubrication and Grease Management

Labyrinth seals need the right amount of grease. Too little leaves the seal exposed to contaminants. Too much creates buildup that traps moisture and dirt.

Hand greasing only keeps the seal protected for a limited time. After that window closes, contamination sneaks in. Automated or periodic greasing systems work better, but they need monitoring to verify they’re actually functioning.

Water ingress into grease is particularly damaging. When high-pressure water is used to clean equipment (common in mining operations), water can be forced backward through seals and into bearing grease. Excess grease buildup makes this problem worse by trapping water against the seal surface.

Operators need to verify that greasing procedures match equipment specifications. Check that grease type is compatible with the seals and operating temperature. Too much or too little lubrication creates problems—the goal is the right amount at the right time.

7. Pressure and Leakage Issues

Labyrinth seals control leakage through passages designed to release pressure gradually. When clearances become nonuniform or seal components wear, pressure control fails and leakage explodes.

Clearance size has the biggest impact on seal performance. Even tiny changes from wear or thermal effects drastically increase leakage. Rotational speed and thermal expansion constantly shift effective clearances.

When leakage increases from equipment that previously ran dry, listen to what your seal is telling you. Rising leakage means wear is happening, clearances are degrading, or thermal issues are developing inside.

Track leakage trends and pressure readings. These give you early warning of seal failure. If leakage is rising but you see no visible damage, internal wear or thermal stress is working behind the scenes.

Conclusion

Labyrinth seal failures rarely explode out of nowhere. Contamination, thermal stress, vibration, and material wear all build up gradually. When you understand what causes these failures, you spot the warning signs early: rising temperature, increasing vibration, growing leakage, or visible damage. You catch the problem before complete failure hits.

Your seals don’t wear during normal operation. That means most damage comes from installation mistakes, running equipment out of spec, or maintenance procedures that introduce contamination. Control these factors during installation and routine operation, and your labyrinth seals will work reliably for years.