Pool pump seal failures can be frustrating and costly, often requiring expensive repairs or replacement.

Many pool owners are unaware of the various factors that can lead to premature seal failure, leaving them unprepared to prevent or address these issues.

In this blog post, we’ll explore the most common causes of pool pump seal failures, including normal wear and tear, improper installation, dry running conditions, chemical degradation, excessive vibrations, pressure fluctuations, and debris. By understanding these factors, you can take proactive steps to extend the life of your pool pump seals and avoid costly downtime.

Normal Wear and Tear

Pool pump seals, like any mechanical component, are subject to normal wear and tear over time. The constant rotation of the pump shaft, friction between the seal faces, and exposure to pool water gradually degrade the seal materials. Even with proper maintenance and ideal operating conditions, seals will eventually wear out and require replacement.

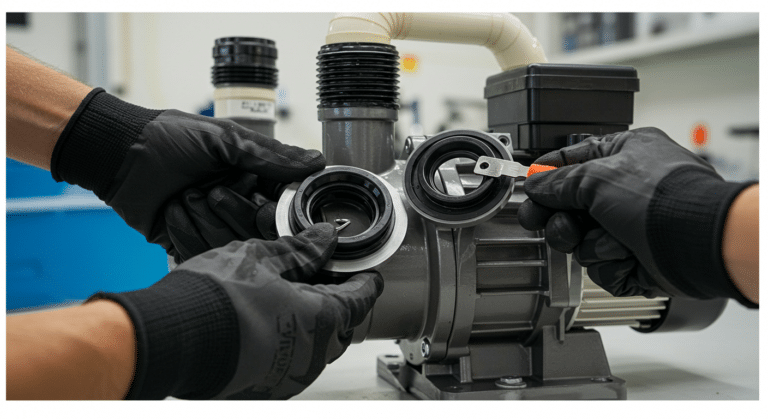

Improper Installation and Alignment

Incorrect installation and misalignment of the pump and motor can lead to premature seal failure. When the pump and motor shafts are not properly aligned, it creates uneven wear on the seal faces, causing them to deteriorate more quickly. Misalignment can also cause excessive vibration, which further damages the seal and other pump components.

Dry Running Conditions

Dry running occurs when the pump operates without sufficient water flow, causing the seal faces to overheat and fail rapidly. Several factors can contribute to dry running conditions:

- Low water levels in the pool: When the water level drops below the skimmer inlet, air can enter the pump system, disrupting proper water flow and causing the pump to run dry.

- Air leaks in the pump system: Leaks in the suction-side plumbing, such as cracked pipes, loose connections, or damaged O-rings, allow air to enter the pump, leading to dry running.

- Restarting the pump without proper priming: After maintenance or a power outage, restarting the pump without first filling it with water (priming) can cause dry running and seal damage.

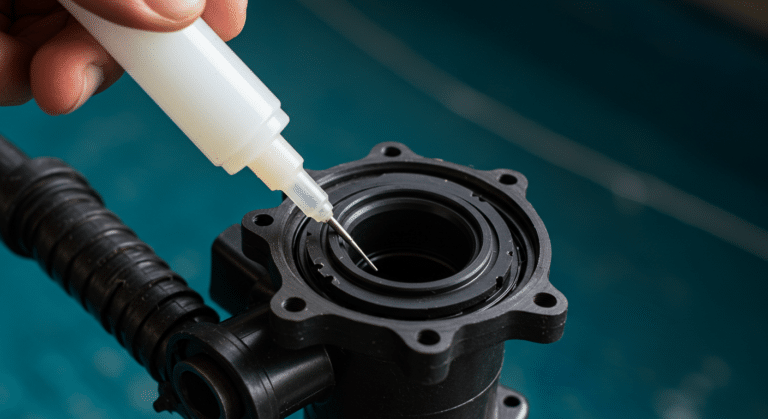

Chemical Degradation of Seal Materials

The chemicals used to maintain pool water balance and hygiene can adversely affect the materials used in pump seals, leading to premature failure. Some common chemical-related issues include:

- Seal plate issues: The seal plate, which houses the stationary part of the seal, can deteriorate due to corrosion or scale build-up caused by imbalanced pool chemistry. A damaged seal plate can cause leaks and seal failure.

- Low PH and high chlorine levels: Acidic water (low pH) and excessive chlorine can attack the seal materials, particularly the elastomeric components, causing them to become brittle and fail prematurely.

- Saltwater pool issues: While salt chlorinators are popular for their convenience, the high salt content in the water can accelerate corrosion of metal components in the pump, including the seal plate and spring.

Excessive Vibrations and Shocks

Excessive vibrations and shocks can cause significant damage to pool pump seals over time. When a pump experiences excessive vibration, it can cause the seal faces to chatter or bounce against each other, leading to premature wear and failure.

Some common causes of excessive vibration in pool pumps include:

- Imbalanced impeller: If the impeller is not balanced properly, it can cause the pump to vibrate excessively during operation.

- Worn or damaged bearings: Worn or damaged bearings can allow the pump shaft to wobble or vibrate, putting extra stress on the seals.

- Loose mounting bolts: If the pump is not securely mounted to its base, it can vibrate or move during operation, causing damage to the seals.

- Cavitation: Cavitation occurs when the pump is starved for water, causing the impeller to spin in a vacuum and create intense vibrations.

Pressure Fluctuations and Water Hammer Effect

Pressure fluctuations and water hammer effects can cause severe damage to pool pump seals, leading to premature failure. These issues arise from:

- Sudden valve closures: Abruptly closing valves in the plumbing system can create pressure spikes that stress the seal and other pump components, causing damage and leaks.

- Improper startup procedures: Starting the pump against a closed discharge valve or without proper priming can create a water hammer effect, where a shockwave travels through the plumbing system, damaging the seal and other components.

Debris

Debris in the pool water, such as leaves, twigs, sand, or small toys, can cause seal failure if they enter the pump system. When debris gets trapped between the seal faces or around the impeller, it can cause scratches, abrasions, or even breakage of the seal components, leading to leaks and premature failure.