Bearing seals are protective barriers that keep lubricants inside bearings while blocking out dirt, water, and other contaminants. Without them, your bearing would fail within days or even hours, turning expensive machinery into scrap metal.

Think of a bearing seal like the rubber gasket around your car door. Just as that gasket keeps rain out while keeping the air conditioning in, bearing seals create a crucial barrier that determines whether your equipment runs smoothly for years or grinds to a halt.

The type of seal you choose can mean the difference between replacing bearings every few months or having them last for decades. Let’s break down the main types and help you pick the right one for your needs.

Contact Seals

Contact seals physically touch the rotating shaft to create a tight barrier against contamination. They’re like a weatherstrip on a window that presses firmly against the glass to block drafts.

These seals excel at keeping out water, dust, and debris because they form an actual physical barrier. You’ll find them in dusty environments like mining equipment, agricultural machinery, and food processing plants where contamination is a constant threat.

The downside is friction. Because the seal rubs against the shaft, it generates heat and wears down over time. This makes contact seals unsuitable for high-speed applications—anything above 3,000 RPM typically causes them to overheat and fail.

Contact seals work best when you need maximum protection and can accept slightly higher operating temperatures. They’re perfect for slow-moving equipment that faces harsh conditions.

Non-contact Seals

Non-contact seals maintain a tiny gap between the seal and the shaft, typically just a few thousandths of an inch. Picture holding your hand just above a hot stove—close enough to feel the heat but not touching.

Because there’s no physical contact, these seals generate almost no friction or heat. This makes them ideal for high-speed applications like electric motors, spindles, and turbines that can spin at 10,000 RPM or more.

The tradeoff is less protection. That tiny gap means some contaminants can potentially sneak through, especially very fine dust or mist. Non-contact seals work best in relatively clean environments where speed matters more than absolute protection.

You’ll want non-contact seals when your equipment runs fast and hot. They’re the go-to choice for precision machinery where even slight friction would cause problems.

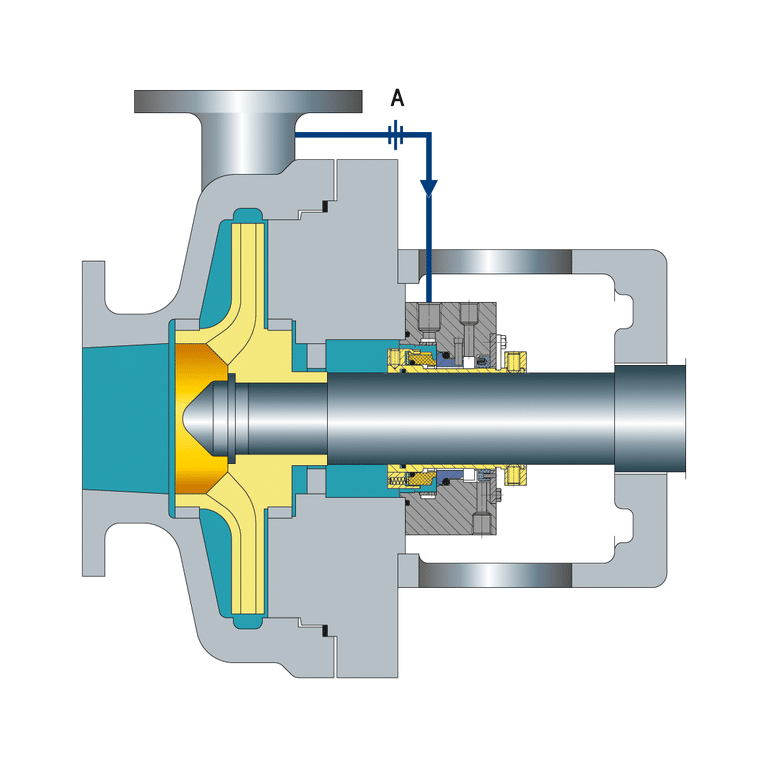

Labyrinth Seals

Labyrinth seals create a maze-like path that forces contaminants to navigate multiple twists and turns before reaching the bearing. Imagine trying to walk through a hedge maze—even if there’s technically a path through, it’s so complicated that most people give up.

These seals use a series of grooves, chambers, and channels to trap particles and fluids. Each turn in the labyrinth causes contaminants to lose energy and drop out before they can reach the bearing.

The beauty of labyrinth seals is they offer excellent protection without any contact at all. They can handle high speeds, high temperatures, and never wear out because nothing touches.

Labyrinth seals shine in heavy industrial applications like steel mills, paper plants, and chemical processing facilities. They’re particularly effective when you can add grease to the labyrinth channels, creating an even more effective barrier.

Selecting the Right Bearing Seal

Choosing the correct seal requires balancing five key factors that determine your bearing’s performance and lifespan:

- Speed requirements – Contact seals max out around 3,000 RPM due to friction heat. Non-contact and labyrinth seals handle speeds up to 20,000 RPM or higher.

- Contamination level – Heavy contamination (water, mud, metal chips) demands contact seals or complex labyrinths. Light dust or clean environments can use simpler non-contact designs.

- Temperature range – High-temperature environments need non-contact or labyrinth seals since friction from contact seals adds unwanted heat. Cold environments may require special materials.

- Maintenance access – Contact seals need regular replacement due to wear. Labyrinth seals can run maintenance-free for years but cost more upfront.

- Cost constraints – Basic contact seals cost the least but need frequent replacement. Labyrinth seals cost 3-5 times more initially but can outlast multiple sets of contact seals.

Start by identifying your biggest threat: contamination or speed. If contamination is severe, lean toward contact seals. If speed is critical, go non-contact. When you need both, invest in a labyrinth seal system.

FAQs

How often should bearing seals be replaced?

Contact seals typically last 2,000-5,000 operating hours depending on speed and contamination. Non-contact and labyrinth seals can last the bearing’s entire lifetime if properly maintained. Check manufacturer recommendations for your specific application.

Can I upgrade from contact to non-contact seals?

Yes, but you’ll need to verify shaft tolerances and housing dimensions match the new seal specifications. Non-contact seals require tighter tolerances to maintain their precise gap. Consult your bearing manufacturer for compatibility.

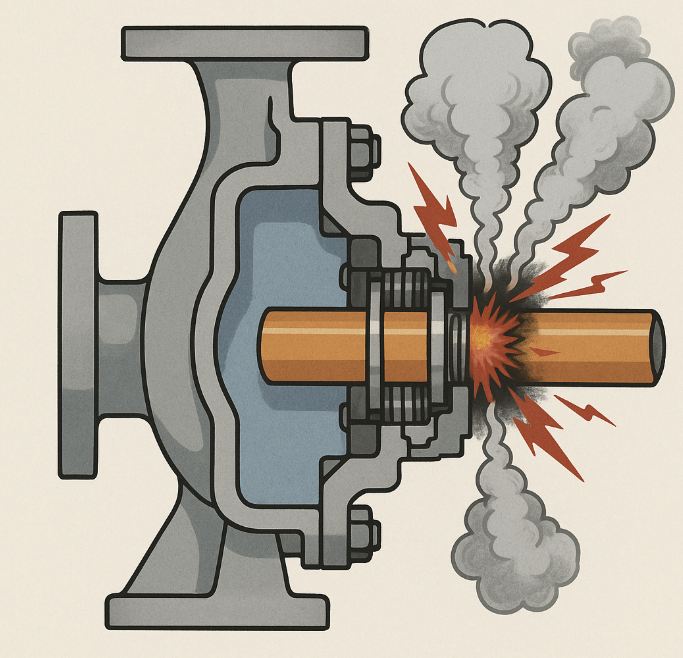

What causes bearing seals to fail prematurely?

Improper installation causes 40% of seal failures. Other common causes include shaft misalignment, excessive vibration, wrong seal material for the chemicals present, and operating beyond the seal’s speed or temperature ratings.

Are more expensive seals always better?

Not necessarily. A simple contact seal might outlast an expensive labyrinth seal in the wrong application. Match the seal type to your specific operating conditions rather than assuming higher cost equals better performance.

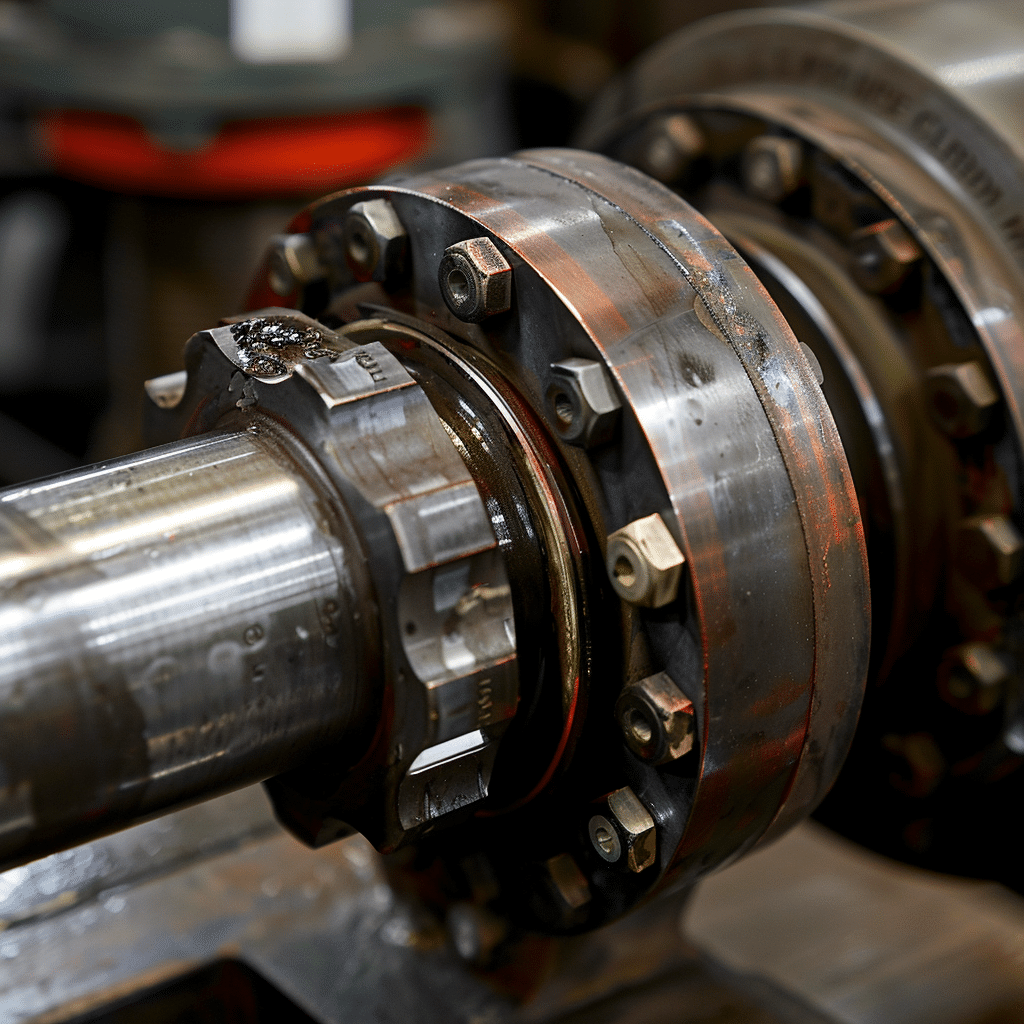

How do I know if my bearing seal has failed?

Look for grease leaking out, unusual bearing noise, increased operating temperature, or visible contamination inside the bearing housing. Any of these signs indicate immediate seal inspection is needed.