Mechanical seals need a tiny amount of leakage to work properly. This small leak actually helps lubricate and cool the seal faces, making them last longer.

Mechanical Seal Leak Rate Calculator

Calculate leakage based on the basic leak rate formula.

Input Parameters

Calculated Leak Rate (Q)

Calculation Breakdown

ln(r₂/r₁) = 0.000

h³ = 0.00e+0 m³

Numerator (π × h³ × ΔP) = 0.00e+0

Denominator (6 × η × ln(r₂/r₁)) = 0.00e+0

The Basic Leak Rate Formula

The most common formula for calculating mechanical seal leak rate is:

Q = (π × h³ × ΔP) / (6 × η × ln(r₂/r₁))

Where:

- Q = leakage rate (m³/sec or in³/sec)

- r₁ = inner face radius (mm or inches)

- r₂ = outer face radius (mm or inches)

- h = gap height between faces (μm or μin)

- ΔP = pressure difference across seal (Pa or psi)

- η = dynamic viscosity of fluid (Pa·s or lbf-sec/in²)

- ln = natural logarithm

This formula works best when the seal faces are running on a thin liquid film with minimal contact.

Example Calculation

Let’s work through a real example:

Given values:

- Inner radius (r₁) = 26.98 mm

- Outer radius (r₂) = 31.75 mm

- Gap height (h) = 0.254 μm

- Pressure difference (ΔP) = 1.8 MPa (1,800,000 Pa)

- Viscosity (η) = 0.001 Pa·s (water at 20°C)

Step 1: Calculate ln(r₂/r₁)

ln(31.75/26.98) = ln(1.177) = 0.163

Step 2: Calculate h³

(0.254 × 10⁻⁶)³ = 1.638 × 10⁻²⁰ m³

Step 3: Put it all together

Q = (3.14159 × 1.638 × 10⁻²⁰ × 1,800,000) / (6 × 0.001 × 0.163)

Q = 9.26 × 10⁻¹⁵ / 9.78 × 10⁻⁴

Q = 9.47 × 10⁻¹² m³/sec

Converting to more practical units:

9.47 × 10⁻¹² m³/sec = 0.34 mL/hour

Alternative Formula for Special Cases

For externally pressurized seals, you might see this more complex formula:

Q = 7.5 × 10⁻¹⁵ × (1 + 0.0013 × D)³ × n¹·⁹ × h⁻⁰·¹ × (k + pf)⁻⁰·⁹ × Dp⁰·¹

This formula includes additional factors like shaft diameter (D), speed (n), and face pressure (pf).

Normal vs. Excessive Leakage

What’s considered normal? Most mechanical seals leak between 5-10 cc/hour (cubic centimeters per hour) during normal operation. That’s about 1-2 teaspoons per hour.

If your calculated or measured leak rate is much higher, it could mean:

- Damaged seal faces

- Improper installation

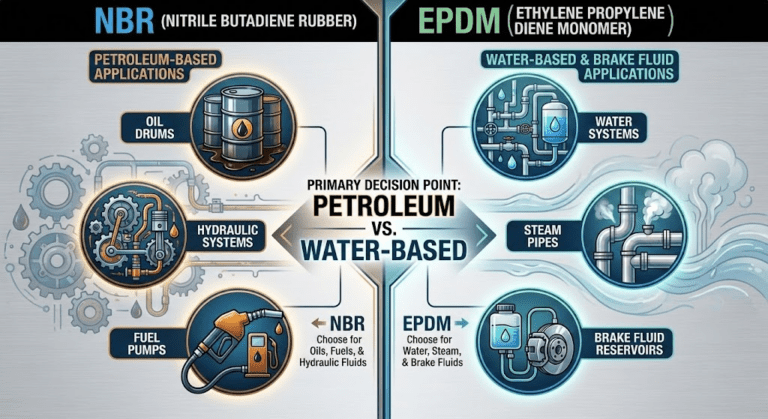

- Wrong materials for your fluid

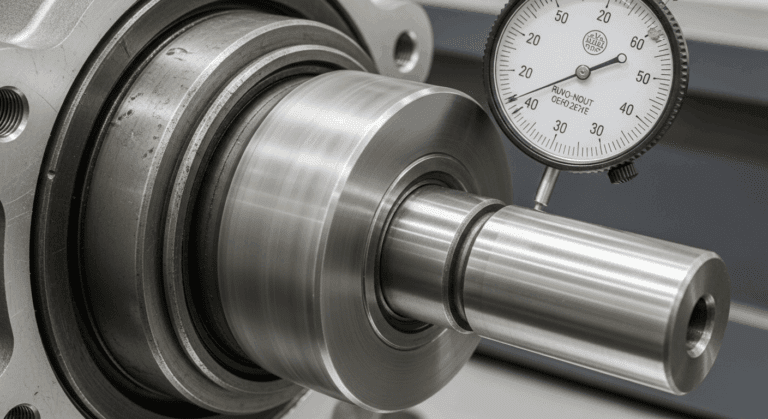

- Excessive vibration or misalignment

When Formulas Don’t Work

Sometimes you can’t calculate leak rate accurately because:

- Seal faces are damaged or worn unevenly

- There’s no stable liquid film between faces

- The seal is running dry or semi-dry

- Multiple leak paths exist

In these cases, you’ll need to measure actual leakage or replace the seal.

Measuring Actual Leak Rate

If you need to verify your calculations:

- Collect leakage over a set time period

- Measure the volume collected

- Calculate rate = volume / time

Remember to account for evaporation if dealing with volatile fluids.