Globe valves are essential components in various industrial applications, regulating and controlling the flow of fluids. This article explores the inner workings, components, and applications of globe valves, providing a comprehensive understanding of their functionality and importance in fluid control systems.

What Is a Globe Valve

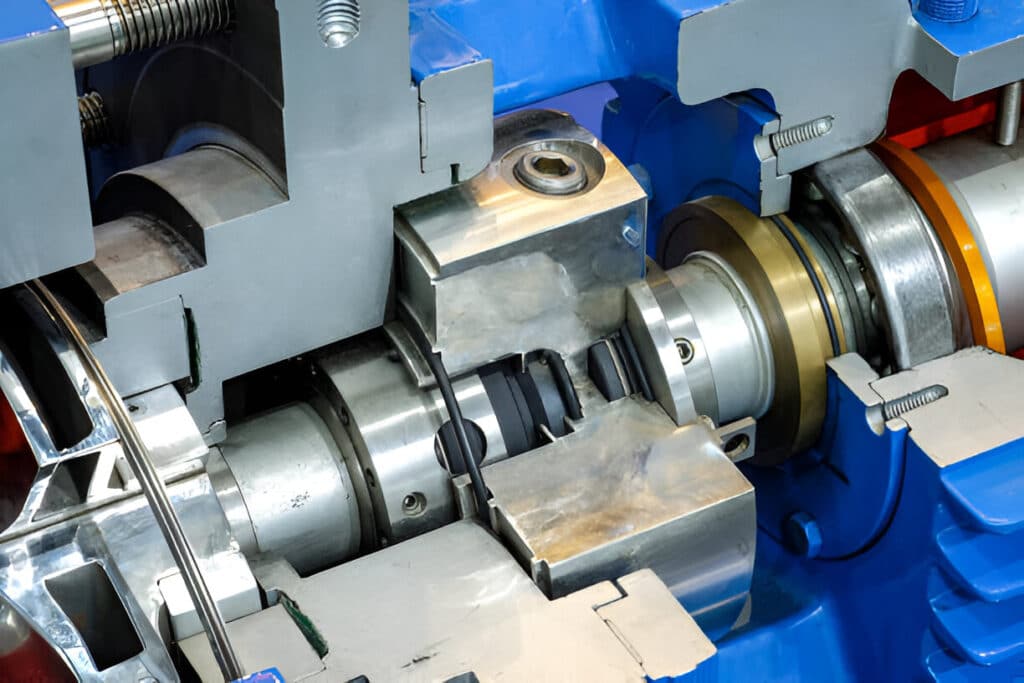

A globe valve is a type of linear motion valve that controls flow by using a movable plug or disc to open, close, or partially obstruct an opening in the valve body. The name “globe valve” refers to the spherical body shape of the valve, which allows for efficient operation and precise control over flow rate.

How Globe Valves Work

Globe valves operate by using a movable disc or plug to control flow through the valve body. When the disc is seated against the valve seat, flow is stopped. As the disc is lifted away from the seat, fluid can pass through the opening between the disc and seat. The position of the disc, controlled by the stem and actuator, determines the flow rate through the valve.

Components of Globe Valve

Body

The body is the main component of a globe valve, providing the primary pressure boundary. Globe valve bodies are typically made from cast iron, bronze, or stainless steel, depending on the application and the type of fluid being controlled. The body houses the internal components, such as the disc, seat, and stem, and connects to the pipeline through threaded, flanged, or welded end connections.

Bonnet

The bonnet is the part of the globe valve that contains the packing box and provides access to the internal components for maintenance. It is attached to the body using bolts or threads and can be removed to replace or repair the disc, seat, or stem. The bonnet also supports the valve stem and handwheel or actuator.

Disc/Plug

The disc, also known as the plug, is the movable part of the globe valve that controls the flow of fluids by closing against the seat. Globe valve discs can have various designs, such as ball, composition, or plug types, depending on the application and the desired flow characteristics. The disc is attached to the stem and moves up and down to open or close the valve.

Seat

The seat is the stationary part of the globe valve that provides a tight seal when the disc is closed against it. The seat is usually made from a hard, wear-resistant material, such as stainless steel or stellite, and can be integral with the body or a separate ring. The seating surface is precisely machined to ensure a leak-tight closure.

Stem

The stem is the part of the globe valve that connects the disc to the handwheel or actuator, transmitting the linear motion required to open or close the valve. Globe valve stems are typically made from stainless steel and can have a threaded or smooth design. The stem passes through the bonnet and is sealed with packing or a bellows to prevent leaks.

Handwheel/Actuator

The handwheel or actuator is the device used to operate the globe valve by turning the stem and moving the disc. Handwheels are the most common manual operators for smaller globe valves, while pneumatic or electric actuators are used for larger valves or automated control. The handwheel or actuator is mounted on top of the bonnet.

Cage

Some globe valves, particularly those used for throttling or control applications, may include a cage around the disc and seat. The cage guides the disc and provides additional flow characterization, such as equal percentage or linear flow. Cages can also be designed with special features, such as anti-cavitation or low noise trims, to improve the valve performance under specific operating conditions.

What Is a Globe Valve Used For

Globe valves are used in a wide range of applications, including:

- Flow control and throttling in process lines

- Isolation of equipment or sections of piping

- Pressure reduction and regulation

- Chemical feed systems and water treatment

- Boiler feed water and steam systems

- Fuel oil systems and other viscous fluid applications

Types of Globe Valves

T-Type Globe Valve

The T-type or straight pattern globe valve is the most common type of globe valve used in various applications. It features a straight flow path, with the inlet and outlet ports in line with each other. The valve disc moves linearly, perpendicular to the flow, to control the flow rate.

T-type globe valves offer good throttling capability and tight shut-off, making them suitable for regulating flow in steam systems, water systems, and other industrial applications. However, due to the convoluted flow path, they have a higher pressure drop compared to other valve types like ball valves or gate valves.

Angle Globe Valve

Angle globe valves have the inlet and outlet ports at a 90-degree angle to each other, forming an “L” shape. This design allows for a more streamlined flow path compared to T-type globe valves, resulting in a lower pressure drop and improved flow efficiency. The valve disc and seat are angled at 45 degrees, allowing for a straight flow path through the valve body.

Angle globe valves are commonly used in applications where space is limited or where the valve is installed directly after a pipe elbow. They are also used in high-pressure and high-temperature systems, such as boiler feed water systems and steam systems.

Y-Pattern Globe Valve

Y-pattern globe valves, also known as Y-body globe valves, have a unique body design that resembles the letter “Y.” The inlet and outlet ports are angled at 45 degrees to each other, while the valve stem is perpendicular to the flow path. This design provides a more direct flow path compared to T-type globe valves, resulting in lower pressure drops and improved flow capacity.

Y-pattern globe valves are often used in applications where high flow rates and low pressure drops are required, such as in chemical processing plants and power plants. They are also used in applications where frequent maintenance is necessary, as the valve internals can be easily accessed without removing the valve body from the pipeline.

Advantages of Globe Valves

- Excellent throttling and precise flow control compared to other valves

- Reliable tight shutoff when fully closed

- Durable with even seat wear in throttling applications

- Easy maintenance with readily accessible and replaceable trim

Disadvantages of Globe Valves

- Higher pressure drop and flow resistance compared to other valves like ball valves or gate valves

- Larger size and weight for a given flow capacity

- Susceptible to cavitation and erosion damage in certain high-pressure drop applications

- More expensive than simpler valves like ball valves or butterfly valves

FAQs

How Does a Globe Valve Regulate Flow?

A globe valve regulates flow by using a movable disc or plug that seats against a stationary seat in the valve body. As the disc is moved away from the seat, the flow rate increases in direct proportion to the disc position.

What Is the Difference between a Gate Valve and a Globe Valve?

Gate valves are designed for fully open or fully closed operation, while globe valves are better suited for throttling and regulating flow. Gate valves have a straight-through flow path with minimal resistance, while globe valves have a more convoluted flow path and higher pressure drop.

What Is the Difference between a Ball Valve and a Globe Valve?

Ball valves use a rotating ball with a bore to control flow, while globe valves use a linear motion disc or plug. Ball valves are compact, fast-acting, and have low pressure drop, while globe valves offer more precise flow control and better throttling capability.

What Is the Difference between a Stop Valve and a Globe Valve?

“Stop valve” is a general term for valves used to shut off flow, which can include globe valves, gate valves, and other types. Globe valves are a specific type of stop valve that also provides throttling and flow regulation capabilities.

Conclusion

Globe valves are critical components in fluid control systems, offering precise flow regulation and reliable shutoff capabilities. By understanding the design, operation, and applications of globe valves, engineers and technicians can select the appropriate valve for their specific requirements and ensure optimal performance in industrial processes.