Pump seal failure can lead to costly downtime, repairs, and environmental damage in industrial facilities. Detecting seal issues early is crucial, but many maintenance teams struggle to effectively monitor seal health.

Fortunately, there are proven strategies to detect pump seal failure before it’s too late. By monitoring pump performance, checking for visible leaks, analyzing vibration levels, and sampling seal flush fluid, teams can identify and address seal issues proactively. In this post, we’ll dive into each of these techniques and show you how to implement an effective seal monitoring program.

Step 1: Monitor Pump Performance

Regularly monitoring pump performance for detecting early signs of pump seal failure. Key indicators to track include:

- Discharge pressure: A sudden drop in discharge pressure can indicate a failing pump seal allowing fluid to leak.

- Flow rate: Reduced flow rates compared to the pump’s specifications or historical data may point to seal leakage.

- Power consumption: Increased power draw by the pump motor can occur if the seal is damaged and creating drag.

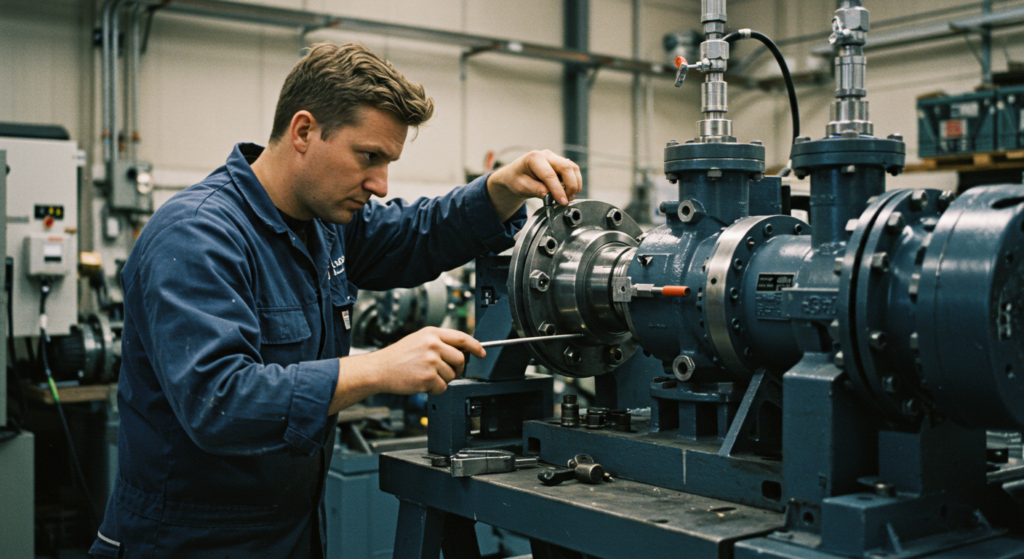

Step 2: Check for Visible Leaks

Visually inspect pumps and surrounding areas for signs of fluid leakage, which is a clear indicator of seal failure. Check for:

- Puddles or drips: Look for any accumulation of liquid around the pump base, seal housing, or nearby piping connections.

- Stains or residue: Seepage from a deteriorating seal may leave behind stains, crystallized deposits, or oily residue on the equipment.

- Abnormal noise: Listen for any hissing, whirring or squealing sounds coming from the seal area during pump operation.

Step 3: Analyze Vibration Levels

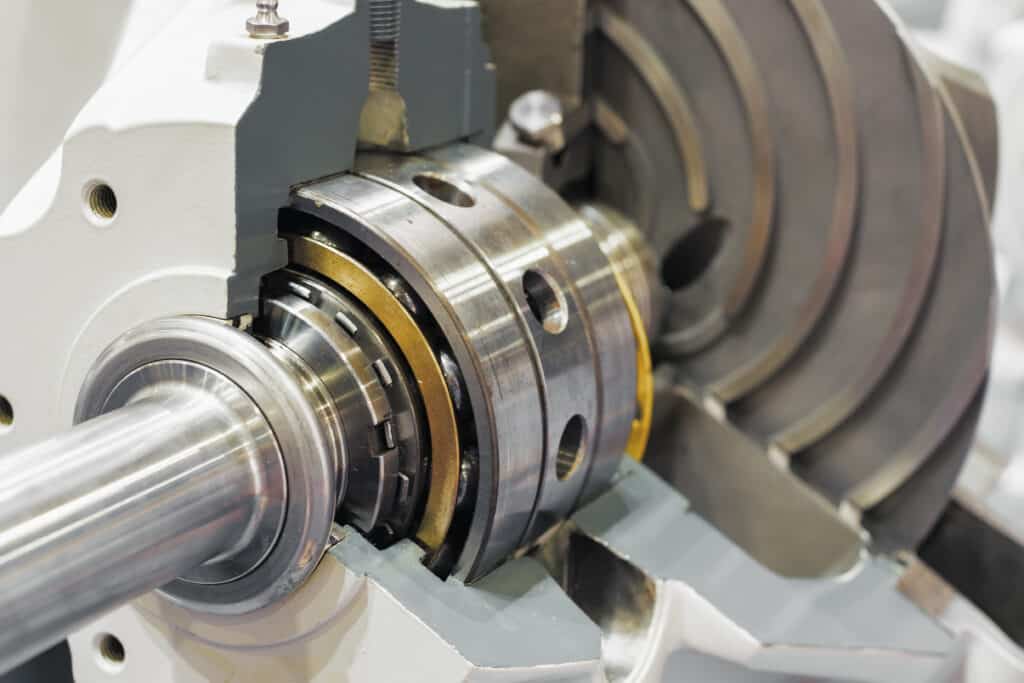

Excessive vibration can lead to premature seal wear and indicate an impending failure. Measure and analyze vibration levels by:

- Vibration sensors: Install accelerometers on the pump housing and bearings to continually monitor for abnormal vibrations.

- Handheld analyzers: Perform periodic vibration checks using portable data collectors and analysis software.

- Frequency analysis: Evaluate the frequency spectrum of the vibration signal to identify problematic frequencies related to seal issues.

Step 4: Sample and Analyze Seal Flush Fluid

Proactively sample and test the seal flush fluid circulating behind the pump seal to detect incipient failures. Look for:

- Particulates: Inspect the fluid for an increase in solid particles, which can indicate seal face wear and debris generation.

- Discoloration: Note any changes to the normal appearance or color of the fluid that may suggest chemical compatibility issues.

- Temperature rise: Check if the fluid temperature downstream of the seal is higher than expected, signifying increased mechanical friction.