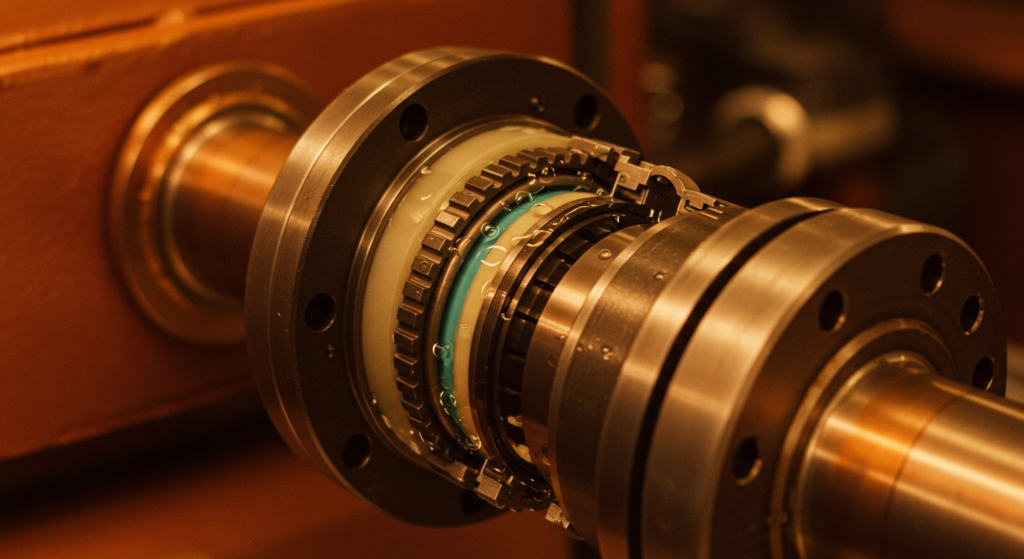

Labyrinth seals protect your equipment by preventing dirt, water, and other contaminants from reaching bearings. Unlike contact seals that press against the shaft, labyrinth seals use a precise gap—often just a few thousandths of an inch—to create a barrier. Get this gap right, and your equipment runs smoothly for years. Get it wrong, and bearings fail unexpectedly.

Understanding Gap Specifications

Standard Gap Sizes

Labyrinth seal gaps are incredibly small. Most standard labyrinth seals have gaps between 0.003 inches and 0.004 inches—that’s roughly 76 to 102 microns. To put this in perspective, a human hair is about 75 microns thick, so you’re working with tolerances that rival a strand of hair.

For rotating equipment with different shaft diameters, manufacturers use a simple rule of thumb: set your radial seal clearance at 0.001 inches per inch of shaft diameter. So if you have a 2-inch diameter shaft, your target gap would be around 0.002 inches. For a 4-inch shaft, aim for 0.004 inches.

Gap Rules of Thumb

The closer the clearance, the better your seal excludes contamination. But there’s a tradeoff: clearances that are too tight limit how much the seal can move, which can cause problems under vibration or thermal stress.

A practical rule in the field is to keep your radial clearance at least 1.5 times the bearing clearance. This prevents rotor dynamic problems and gives the seal room to operate safely without the seal teeth rubbing against the shaft.

When measuring, you’ll typically find that gaps can be as tight as 0.002 inches for precision floating seals, but most industrial equipment uses gaps in the 0.003 to 0.005 inch range.

How Temperature Affects Gaps

Temperature cycling causes gaps to grow over time. When equipment heats up, seal components expand. When they cool, they contract. This constant expansion and contraction gradually increases your seal gap.

Always measure gaps at operating temperature, not cold. A gap that looks fine at room temperature might actually be too large once the seal heats up.

Tools You Need for Measuring

Measuring labyrinth seal gaps requires basic tools you probably already have. Here’s what equipment operators use:

- Feeler Gauge – The most practical tool for field measurements. It’s simple, inexpensive (typically $10-30), and gives you quick results. Get a set with blades ranging from 0.001 to 0.010 inches.

- Dial Indicator – Provides more precise measurements than a feeler gauge, accurate to 0.001 inches. Useful when you need to verify measurements or when working with tighter tolerances.

- Micrometer – For detailed analysis, a micrometer measures down to 0.0001 inches. Not essential for basic gap checking, but valuable if you’re tracking trends or need documentation.

- Compressed Air (30-40 PSI) – Before measuring, clean debris from seal grooves. A portable air compressor or shop air works perfectly.

- Soft Brass Brush or Plastic Scraper – For stubborn deposits in seal grooves. Never use steel tools—they’ll damage the finely machined seal surfaces.

- Clean Cloth or Paper Towels – For wiping sealing surfaces clean before measurement.

Step-by-Step Measurement Procedures

Step 1: Prepare the Equipment

Stop the equipment safely. The best time to measure is when the equipment reaches its normal operating temperature—this shows how the seal performs under real conditions. If you can’t measure during operation, at least wait until the equipment has warmed up. Cold measurements don’t accurately reflect how thermal expansion affects your gap.

Document what you observe: the current temperature, how long the equipment has been running, and any recent maintenance work.

Access the seal carefully. Depending on your equipment, you might need to remove a small cover or guard. Clean away any visible dirt or grease around the seal area using your cloth.

Step 2: Identify Measurement Points

Check the gap at four locations around the seal: 12 o’clock, 3 o’clock, 6 o’clock, and 9 o’clock positions. Mark them or just mentally note where they are.

This reveals the full picture. An uneven gap—wide in one spot, tight in another—means the seal is tilted or damaged.

Step 3: Use the Feeler Gauge Method

Start with your thinnest blade and insert it gently between the seal teeth and shaft at 12 o’clock. Find the blade that slides with light pressure—snug but not forced, not loose.

Move to all four measurement points and record each blade thickness. Identical measurements mean even wear. Variations larger than 0.001 inches signal alignment issues.

Go slow. Forcing a gauge damages the seal, and rushing produces bad readings.

Step 4: Verify with Dial Indicator (Optional)

For more precision, mount a dial indicator on a stand with the probe tip touching the shaft. Rotate the shaft slowly while watching the dial. The difference between highest and lowest readings is the radial runout—how much the shaft moves.

Measure at the same four points you used with the feeler gauge. Compare the dial readings to your feeler gauge results—they should match closely. If they don’t, recheck your feeler gauge technique.

Step 5: Record and Compare Results

Write down all four measurements. Calculate the average gap and compare it to your equipment’s specification—usually found in the maintenance manual or on the seal itself.

Create a simple record:

- Date and temperature

- Equipment identification

- Gap measurements at 12, 3, 6, and 9 o’clock

- Average gap vs. specification

- Any visible seal damage

Track these records over time. Gaps that grow slowly over months mean normal wear. Gaps that suddenly jump suggest a real problem.

Common Problems and What They Mean

| Problem | Measurement | What’s Happening | What to Do |

|---|---|---|---|

| Gap Too Large | 0.007″ or larger | Contaminants entering bearing; seal worn out | Replace seal immediately |

| Gap Growing Slowly | Increases 0.001-0.002″ over 6 months | Normal wear from thermal cycling | Plan replacement in next maintenance window |

| Uneven Gap | Variation >0.001″ around circumference | Seal tilted, misaligned, or damaged | Check seal installation; replace if teeth damaged |

| Gap Too Small | 0.001″ or less | Possible seal or shaft rubbing; friction heating | Inspect for damage; check alignment |

| Sudden Gap Change | Changes >0.002″ between measurements | Contamination, vibration damage, or bearing wear | Stop equipment; inspect bearing and seal |

| Visible Debris in Grooves | Any gap size | Contaminant ingress failing seal function | Clean with compressed air; monitor closely |

| Asymmetrical Wear Pattern | Groove erosion visible at one spot | Contamination accumulation; possible bearing issues | Replace seal; flush bearing area |