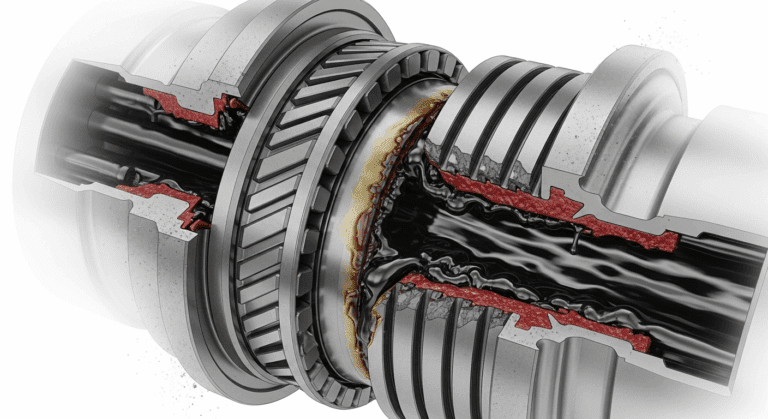

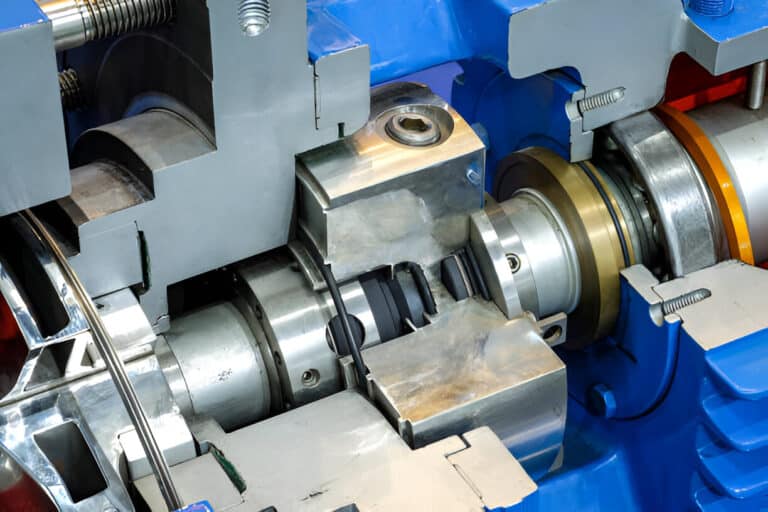

Labyrinth mechanical seals work like a maze for fluids and gases, creating a tortuous path that prevents leakage without any physical contact between parts. These non-contact seals are workhorses in rotating equipment like turbines, compressors, and pumps because they don’t wear out from friction like traditional seals.

Proper maintenance of labyrinth seals can extend their life from months to years, saving you thousands in replacement costs and preventing costly equipment downtime.

How to Inspect Labyrinth Seals

You should inspect your labyrinth seals every 3-6 months during routine equipment checks. Look for three main things: visible damage to the seal teeth, buildup of debris in the grooves, and signs of excessive leakage around the seal area.

Here’s your inspection checklist:

- Check the clearance gap – Use a feeler gauge to measure the gap between the seal teeth and the shaft. If it’s more than 0.5mm larger than the original specification, you’ve got a problem.

- Look for bent or broken teeth – Shine a flashlight into the seal area and check each tooth. Even one damaged tooth can reduce sealing effectiveness by 30%.

- Inspect for contamination – Look for dirt, process material, or corrosion products stuck in the labyrinth grooves. Think of it like checking your car’s air filter—debris blocks the seal’s ability to work properly.

- Monitor leakage rates – Compare current leakage to baseline measurements. A 50% increase means it’s time for maintenance.

Cleaning Labyrinth Seals Properly

Cleaning is 80% of labyrinth seal maintenance, and you can do it without removing the seal from the equipment.

Start by using compressed air at 30-40 PSI to blow out loose debris from the grooves. Work from the inside out, just like you’d clean a keyboard.

For stubborn buildup, use a soft brass brush or plastic scraper to gently remove deposits. Never use steel tools—they’ll damage the precisely machined seal teeth.

Apply a solvent appropriate for your process (typically isopropyl alcohol or mineral spirits) with a spray bottle to dissolve any remaining contamination. Let it soak for 5 minutes, then blast it out with compressed air again.

When to Replace vs. Repair

Replace your labyrinth seal immediately if more than 20% of the teeth are damaged or if the clearance has increased beyond manufacturer tolerances.

Minor damage to 1-2 teeth can often be repaired by carefully filing down sharp edges that might cause further damage. This is like filing a broken fingernail—you’re preventing it from catching and tearing further.

If you’re seeing steady increases in leakage despite regular cleaning, the seal has likely reached the end of its service life and needs replacement.

FAQs

How often should a labyrinth seal be replaced?

Labyrinth seals typically last 3-5 years with proper maintenance, though some run for 10+ years in clean service. Replace them when clearances exceed manufacturer specs by 50%, when more than 20% of teeth are damaged, or when leakage rates become unacceptable despite cleaning.

Do labyrinth seals need lubrication?

No, labyrinth seals are non-contact devices that don’t require lubrication. In fact, adding grease or oil can attract contaminants and clog the labyrinth grooves, reducing sealing effectiveness.

How do I measure labyrinth seal clearance?

Use feeler gauges to measure the gap between seal teeth and the shaft at four points (12, 3, 6, and 9 o’clock positions). Record all measurements and compare them to the manufacturer’s specifications to determine if replacement is needed.